working principle:

SP-LDE series papermaking white liquid flowmeter, slurry type dedicated flowmeterBased on Faraday's law of electromagnetic induction. The conductive medium inside the measuring tube is equivalent to a conductive metal rod in Faraday's test, and the two electromagnetic coils at the upper and lower ends generate a constant magnetic field. When a conductive medium flows through, an induced voltage is generated. The induced voltage generated by measuring the two electrodes inside the pipeline. The measuring pipeline achieves electromagnetic isolation from the fluid and measuring electrode through non-conductive lining (rubber, Teflon, etc.), as shown in the figure.

Advantages and unique selling points:

1. The most important component of the sensor - the coil - is optimized in design and undergoes the strictest real current tests to ensure the measurement accuracy of the product

2. The signal electrode undergoes thorough electrostatic shielding treatment to ensure that small signals are not interfered by the coil and to guarantee measurement accuracy at low flow rates

3. The coil is isolated from the outside world to ensure its long-term insulation strength, which in turn guarantees the long-term measurement accuracy of the sensor

4. All welding processes of the sensor are carried out using argon arc welding technology. Although the cost is high, it can ensure the reliability of welding (welding is the main production process of the sensor), especially the last welding process after installing the coil. Using argon arc welding technology can ensure that the installed coil is not damaged

5. Adopting a grounding electrode structure to form a balanced electrode plane ensures that the entire process of measuring the average speed is limited to the balanced electrode plane, which can effectively eliminate electrical noise interference and provide accurate measurement results

6. Adopt customized double-layer shielded cables

7. Programmable low-frequency rectangular wave excitation improves the stability of flow measurement and reduces power loss

8. High frequency excitation is used for measuring special media (such as slurry) to eliminate clutter interference

9. Adopting a 16 bit embedded microprocessor, it has fast computing speed and high accuracy

10. All digital processing, strong anti-interference ability, reliable measurement, high accuracy

11. Ultra low EMI switching power supply, suitable for a wide range of power supply voltage changes, with good EMC resistance performance

12. Complete all functional designs with a single circuit board, using SMD devices and surface mount SMT (SMT) technology for high circuit reliability

13. High definition backlit Chinese LCD display, displaying cumulative flow rate, instantaneous flow rate, flow percentage, etc

14. Menu operation, easy to use, simple to operate, easy to learn and understand

15. Bidirectional measurement system, with three integrators inside that can display forward cumulative quantity, reverse cumulative quantity, and differential cumulative quantity respectively

16. Equipped with self checking and self diagnostic functions, and displayed on the screen

17. Unique lightning protection design

Key points for selection:

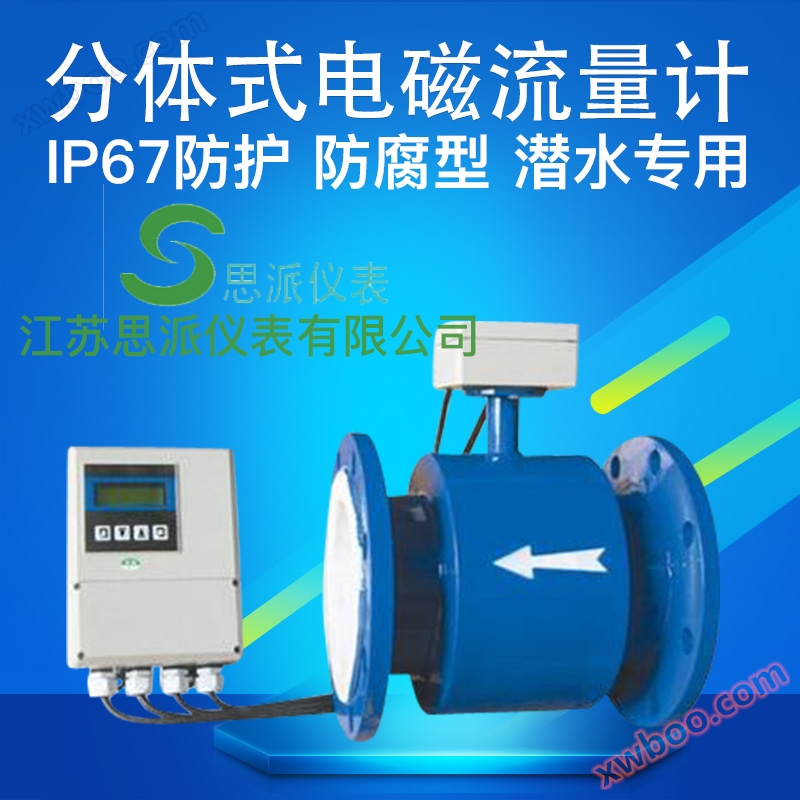

1. Choose the appropriate type based on the characteristics of integrated and separated electromagnetic flow meters. The installation and wiring of the integrated electromagnetic flowmeter are convenient, with moderate accuracy, and should not be installed below the ground to prevent the converter from being submerged in water. The separated electromagnetic flowmeter has high accuracy, and the converter and sensor are installed in different locations, making it more suitable for situations with poor on-site environment (such as hazardous, toxic, and easily flooded places). However, the installation and wiring are strict, otherwise interference signals may be introduced.

2. Choose the appropriate electrode form. For media that do not produce crystals, scars, or contaminate electrodes, standard electrodes can be used. Otherwise, scraper type cleaning electrodes or electrodes with cleaning connection devices can be used. For sludge testing, replaceable electrodes can also be used.

3. Select electrode materials based on the corrosiveness of the tested medium.

4. Select lining materials based on the corrosiveness, wear resistance, and temperature of the tested medium.

5. Protection level. According to the national standard GB4208-1984, which is approximately equivalent to the International Electrotechnical Commission IEC standard (IEC529-7B), the standard for the protection level of the enclosure is IP65, which is a waterproof type that allows the faucet to spray water on the instrument from any direction, with a spray pressure of 30Kpa. The water output is 0.75m3/h, and the distance between the water spray port and the instrument is 3m. IP67 is a waterproof type, which means that the instrument can be completely immersed in water, and the highest point should be at least 150cm underwater for at least 30 minutes. IP68 is a submersible type that can work underwater for a long time. According to the above regulations, instruments that are prone to flooding when installed underground should be rated IP68, while instruments installed above ground should be rated IP65.

Paper white liquid flowmeter, slurry type special flowmeter| Selection of electrode materials and lining materials | ||||||||||||

|

The user should be responsible for selecting based on the corrosiveness of the tested medium. For general media, relevant anti-corrosion manuals can be consulted to select the material of the electrode. For media with complex components such as mixed acids and bases, hanging plate tests should be conducted. |

||||||||||||

|

| model | caliber | |||||

| SP-LDE | 15~2600 | |||||

| code | Electrode material | |||||

| K1 | 316L | |||||

| K2 | HB | |||||

| K3 | HC | |||||

| K4 | titanium | |||||

| K5 | tantalum | |||||

| K6 | platinum alloy | |||||

| K7 | Stainless steel coated with tungsten carbide | |||||

| code | Lining material | |||||

| C1 | Polytetrafluoroethylene (F4) | |||||

| C2 | Perfluoroethylene propylene (F46) | |||||

| C3 | Polyfluoroethylene (FS) | |||||

| C4 | Polyvinyl rubber | |||||

| C5 | polyurethane rubber | |||||

| code | function | |||||

| E1 | Level 0.3 | |||||

| E2 | Level 0.5 | |||||

| E3 | Level 1 | |||||

| F1 | 4-20Madc, Load ≤ 750 Ω | |||||

| F2 | 0-3kHz, 5V active, variable pulse width, output high-end effective frequency | |||||

| F3 | RS485 interface | |||||

| T1 | Normal temperature type | |||||

| T2 | High temperature type | |||||

| T3 | Ultra high temperature type | |||||

| P1 | 1.0MPa | |||||

| P2 | 1.6MPa | |||||

| P3 | 4.0MPa | |||||

| P4 | 16MPa | |||||

| D1 | 220VAC±10% | |||||

| D2 | 24VDC±10% | |||||

| J1 | Integrated structure | |||||

| J2 | Split type structure | |||||

| J3 | Explosion proof integrated structure | |||||