Overview

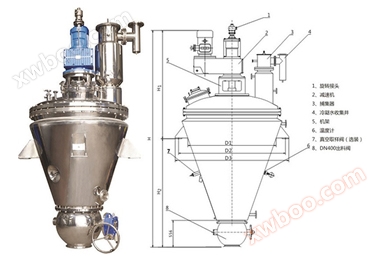

ZDG seriesVacuum ribbon dryerThis is a new generation of vacuum drying and mixing equipment developed by our factory to digest and absorb similar foreign products. The equipment integrates drying, crushing, vacuum pressure reduction, and powder mixing. It consists of a motor, reducer, frame, mechanical seal, filter, spiral stirrer, conical cylinder with jacket heating, and discharge valve. It can achieve continuous operation of the entire process in a closed manner. Its drying efficiency is 3-5 times that of the SZG series double cone rotary vacuum dryer of the same specifications. It is mainly used for powder drying in industries such as pharmaceuticals, chemicals, pesticides, and food, and can achieve continuous operation of the entire process in a closed manner. It is the preferred drying equipment for the above industries.

working principle

The main body of the ZDG series vacuum ribbon dryer is vertically stationary, and the internally heated ribbon undergoes circular stirring and lifting motion. The ribbon agitator is driven by a motor reducer to rotate, and the animal material is carried along the conical cylinder and lifted from bottom to top. After reaching the highest point, the material flows automatically to the center of the vortex and returns to the bottom of the conical cylinder under the action of gravity and inertia. The entire process forces the material to be heated in the conical cylinder, with relative convection and mixing. The heat diffuses in the material, causing the material to undergo irregular reciprocating motion in all directions, completing high-frequency heat transfer and exchange between the material and the cylinder wall surface. The solvent evaporated by heating is extracted in a vacuum state, achieving the effect of heating and drying in a short time.

Features of the equipment

- 1. The parts in contact with equipment and materials are made using materials that comply with GMP requirements.

- 2. Top drive, the equipment has no contact with the outside air, no leakage, and no dead corners during the feeding, drying, mixing, and discharging processes.

- 3. The design, manufacturing, and testing of equipment chambers shall be carried out in accordance with the requirements of pressure vessels.

- 4. The rotating joint adopts GMP approved double end dry mechanical seal, with no foreign objects falling off.

- 5. The chamber and stirring blade are equipped with heating channels, and the stirring blade orderly and uniformly carries animal materials for heat exchange, with a large heating area.

- 6. The material does not hang on the wall or clump during the drying process.

- 7. The smoothness of the contact area with the material: Ra ≤ 0.4um (surface passivation or electrolytic polishing).

- 8. Set up an online sampler.

- 9. Set up a valve top dead corner blowback port.

- 10. Smooth operation, protecting crystal form.

- 11. Low operating energy consumption cost and high mixing efficiency.

- 12. Easy to operate and maintain.

Technical Specifications

| Model | Total volume (L) | Working volume (L) | Heating area (m)2) | Rotational speed (r.p.m.) | Motor power (Kw) | Design pressure inside the tank (MPa) | Design pressure of jacket (MPa) |

| ZDG - 500 | 500 | 350 | 2 | 34 | 4 | -0.09~0.096 | 0.3 |

| ZDG-750 | 750 | 450 | 2.8 | 5.5 | |||

| ZDG-1000 | 1000 | 700 | 3.8 | 7.5 | |||

| ZDG-1500 | 1500 | 1100 | 4.6 | 30 | 11 | ||

| ZDG-2000 | 2000 | 1400 | 6.3 | 26 | 15 | ||

| ZDG-3000 | 3000 | 2100 | 7.1 | 10 | 18.5 | ||

| ZDG-4000 | 4000 | 12800 | 9.5 | 18 | 30 | ||

| ZDG-5000 | 5000 | 3500 | 12.2 | 15 | 45 |