overview

Couplings, also known as couplings. A mechanical component used to firmly connect the active and driven shafts in different mechanisms for rotation, and transmit motion and torque. Sometimes it is also used to connect shafts with other parts such as gears, pulleys, etc. It is often composed of two halves, connected separately by keys or tight fitting, fastened at the ends of the two shafts, and then connected together in some way. Couplings can compensate for offset between two shafts due to manufacturing and installation inaccuracies, deformation during operation, or thermal expansion (including axial offset, radial offset, angular offset, or comprehensive offset); And to mitigate impact and absorb vibration.

Most commonly used couplings have been standardized or normalized, and in general, it is only necessary to correctly select the type of coupling, determine the model and size of the coupling. If necessary, the load capacity of vulnerable weak links can be checked and calculated; When the speed is high, it is necessary to verify the centrifugal force at the outer edge and the deformation of the elastic element, and perform balance verification.

type

Couplings can be divided into two categories: rigid couplings and flexible couplings.

Rigid couplings do not have buffering and compensation capabilities for relative displacement between two axes, requiring strict alignment between the two axes. However, this type of coupling has a simple structure, low manufacturing cost, easy assembly, disassembly, and maintenance, and can ensure high alignment between the two axes. It can transmit large torque and is widely used. Commonly used couplings include flange couplings, sleeve couplings, and clamp shell couplings.

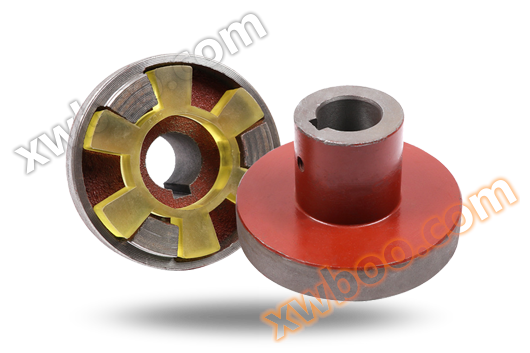

Flexible couplings can be divided into non elastic element flexible couplings and elastic element flexible couplings. The former type only has the ability to compensate for the relative displacement of two axes, but cannot buffer and reduce vibration. Common types include slide couplings, gear couplings, universal couplings, and chain couplings; The latter type, due to the presence of elastic elements, not only has the ability to compensate for the relative displacement of the two axes, but also has buffering and vibration reduction effects. However, the transmitted torque is generally limited by the strength of the elastic elements and is not as good as the flexible couplings without elastic elements. Common types include elastic sleeve pin couplings, elastic column pin couplings, plum blossom couplings, tire couplings, serpentine spring couplings, and reed couplings

Performance Requirement

According to different working conditions, couplings need to have the following performance:

(1) Portability. The mobility of a coupling refers to the ability to compensate for the relative displacement between two rotating components. Factors such as manufacturing and installation errors between connected components, temperature changes during operation, and deformation under load all require mobility. Removable performance compensation or mitigation of additional loads between shafts, bearings, couplings, and other components caused by relative displacement between rotating components.

(2) Buffer capability. For situations where frequent load starting or changes in working load occur, the coupling should have elastic elements that provide buffering and vibration reduction to protect the prime mover and working machine from damage or injury.