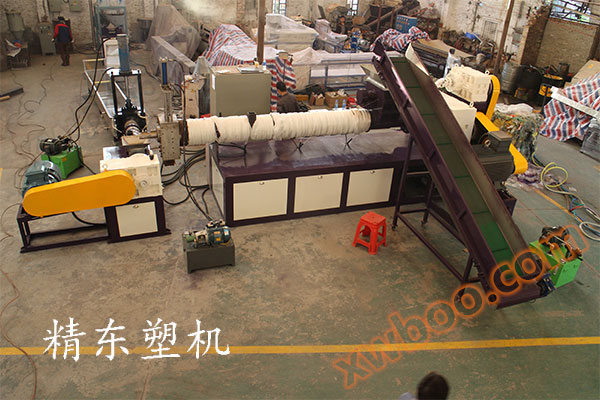

Brand: Jingdong Model: SJ-250

Product alias: PP material granulator Product purpose: Recycling of waste plastics

Type: Granulation extruder Screw number: Twin screw

Screw diameter: 250 (mm) Maximum extrusion diameter: 150 (mm)

Production capacity: 800-1500 (Kg/h) Positioning accuracy: 0.01 (mm)

Dimensions: Customized (mm) Motor power: 75 (kw)

After sales service: quality and quantity guaranteed for one year, lifetime maintenance

The design specifications for extruder screws are Φ 125, Φ 135, Φ 150, Φ 180, Φ 200, Φ 220, and Φ 250

Characteristics of PP granulator for waste woven bags:

1. Plastic PP woven bag PE film granulation recycling machine line, with high output and good granulation capacity (500-1000kg/h).

2. The plastic PP woven bag PE film granulation recycling machine line is widely used for recycling waste PP woven bags and non-woven fabrics into PP particles.

3. Highly automated: One production line has only 2 people.

4. High efficiency: Compared with ST power generation design, POLYTEC2nd has increased the production capacity of PP woven bag granulation and recycling machine production line by 20%.

5. According to the cleanliness of raw materials and actual production needs, single-stage (one extruder with one screen changer) or two-stage (two extruders with two screen changers) can be selected

6. You can choose to use water ring cutting or cooling strip cutting methods to match different raw materials.

The structure of the woven bag granulator is very simple, with two heating rings on each lower screw and a temperature controller on each upper and lower heating ring, which can adjust the temperature according to needs. When using, first heat the granulator for about 20 to 40 minutes, and then put a piece of foam on the machine. If the foam on the machine becomes soft, it means that the temperature is enough and it can work normally. First, add a small amount of foam into the hopper. If the extrudate has melted, a large amount of blanking can be used to start work. If the temperature is too high during work, cut off the heating power supply of the head and continue to work. When the woven bag granulator is working, a layer of filter screen should be added to the screw head below. Several more filter screens should be prepared. If the stripping is not smooth during operation, it indicates that the filter screen is blocked and should be replaced immediately. After the entire use, it is necessary to clear the impurities inside the granulator, so that we can better maintain and upkeep our granulator equipment.

Foshan Nanhai Jingdong Machinery Co., Ltd. is a professional enterprise engaged in the research, development, and manufacturing of plastic machinery equipment with twin-screw extruders, single screw extruders, plastic recycling granulators, pipe machines, rubber strip machines, rattan imitation machines, PVC extruders as the core, as well as related technology and engineering fields, and supporting auxiliary equipment. The equipment is widely used in the production of special materials, masterbatch, engineering modified materials, automotive materials, wires and cables, large plastic pipes, sheets, petrochemicals, chemical fiber construction, medicine, agriculture, and national defense. Our products are exported to countries and regions in Russia, the Middle East, India, North America, Eastern Europe, and North Africa.

'Made for You' is the unchanged characteristic of our enterprise, which meets the requirements of customers, provides technical design, whole machine assembly, on-site debugging and other services, and creates more and greater economic and social benefits for customers in the first time. Our company has been tirelessly pursuing the goal since its establishment. While focusing on the domestic machinery market, we also continuously absorb advanced production technology, scientific management systems, and timely market information from abroad, striving to synchronize our products with the development of the world's machinery. Jingdong Plastic Machinery will always serve you wholeheartedly and work together with you to create a better tomorrow in the market.