Warehouse Material Management System

Warehouse Material Management System

Traditional warehouse management generally relies on a non automated, paper-based system to record and track incoming and outgoing goods, which is entirely implemented manually within the warehouse. Therefore, the efficiency of warehouse management is extremely low. In response, we utilize a warehouse intelligent management system based on RFID wireless radio frequency technology, which can enhance the accuracy and speed of warehouse operations, reduce losses caused by illegal entry and exit, misplacement, theft, inventory and shipment errors due to inadequate management of materials, and minimize storage costs and ensure the safety of materials.

| System functions |

|

Real time monitoring of materials | Real time monitoring of material storage through positioning tags installed on goods to ensure the safety of material entry and exit, |

|

Goods storage registration | Electronic registration of newly stocked materials and binding of location tags. |

|

Outbound and Return Registration | The automatic inventory registration of materials can be achieved through the positioning tags on the materials. |

|

Quick inventory of warehouse | Utilize electronic positioning tags and ultra-high frequency card readers to conduct rapid inventory of the warehouse, check the placement and storage time of goods, and classify and count them. |

|

Quick search for goods | By entering the name or ID number of the goods to be searched on the management software, the location and storage status of the goods can be quickly viewed. |

|

Visualization presentation of materials | Through the three-dimensional images on the software, the distribution of goods in the warehouse can be viewed in real time, making it convenient to quickly locate the location of goods and intuitively view their storage and in place status. |

|

Statistical report function | Generate reports with one click for inventory records, inventory forms, and warehouse information. |

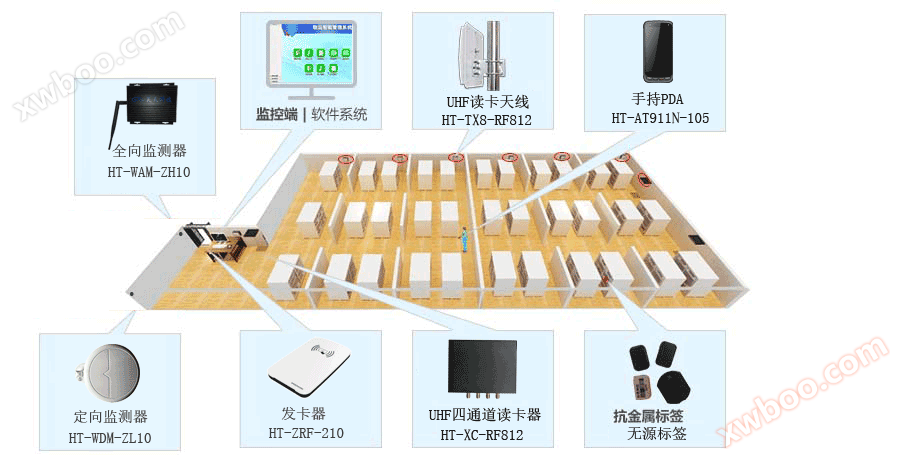

▎ Implementation Architecture

| Management control layer |

|

|

|

printer |

Central server | Software end |

| data collection layer |

|

|

|

|

|

RFID tag desktop card dispenser HT-ZRF-210 |

UHF Four Channel Card Reader HT-XC-RF812 |

handheld RFID reader HT-YRD-105 |

UHF card reading antenna HT-TX8-RF812 |

|

|

||

|

Omnidirectional monitor HT-WAM-ZH10 |

Directional monitor HT-WDM-ZL10 |

|

| Detecting terminal layer |

|

|

||

|

Active material label Ht-zhr- 125 |

RFID passive tag HT-FWR-102 |

|

▎ Product Introduction

| Positioning label |

|

|

|

|

Active material label Ht-zhr- 125 |

RFID passive tag HT-FWR-102 |

| data collection |

|

|

|

|

|

Desktop label dispenser HT-ZRF-210 |

UHF Four Channel Card Reader HT-XC-RF812 |

UHF card reading antenna HT-TX8-RF812 |

Handheld RFID reader/writer HT-YRD-105 |

|

|

|

|

Omnidirectional monitor HT-WAM-ZH10 |

Directional monitor HT-WAM-ZL10 |

▎ Software interface