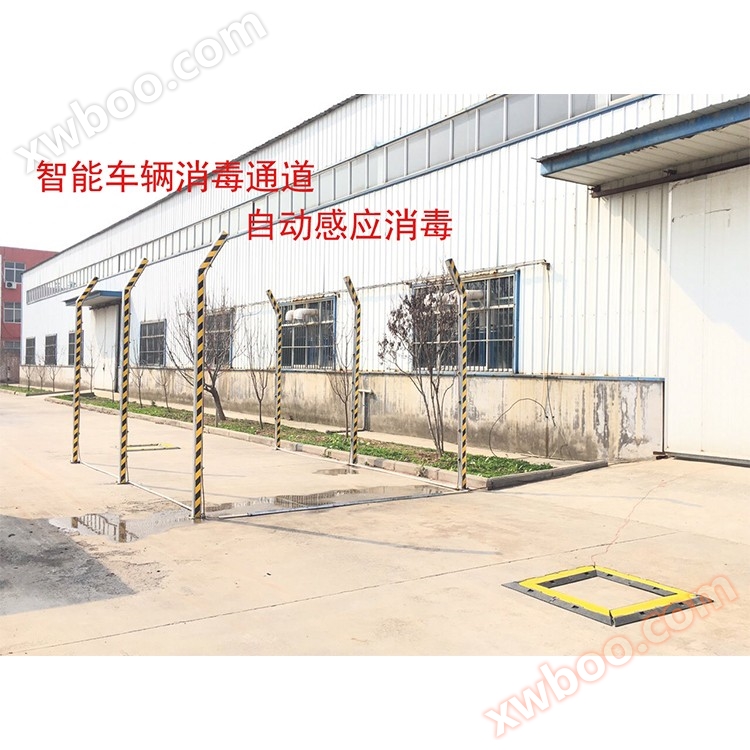

Vehicle disinfection channel series

1. Disinfection object:

To prevent various infectious diseases through epidemic prevention and disinfection;

Vehicle disinfection at the urban-rural junction;

◆ Disinfection of animal and plant transportation and passenger vehicles;

Disinfection of foreign vehicles entering and leaving the country;

Disinfection of taxis, buses, and other vehicles within the city;

◆ Disinfection of vehicles entering and leaving pastures, food factories, feed factories, and meat processing factories;

2. Disinfection method:

(1) When the structure of the vehicle is a box truck or a multi story truck with a fence, the method of disinfecting the entire vehicle includes disinfecting the side, bottom, and upper parts of the vehicle's tires in all directions. The best effect is to wet the vehicle body with the liquid sprayed during disinfection.

(2) The disinfection facility adopts the light sensing control type of ultra-low volume high-pressure spray for disinfection in a short time and with high efficiency. The sprayed disinfectant prevents it from flowing into rivers, land, and preventing secondary pollution.

(3) The spray facility is equipped with an antifreeze device that can operate normally without failure at minus 40 degrees. The spray pipeline has no reverse water return (agent) antifreeze device.

3. Functional features:

1. Equipment and site requirements: The equipment has strong adaptability to the site and environment, can be quickly disassembled and installed, and is easy to install. It can be adjusted according to the site whether it is a passage room or a non passage room. It can be quickly installed at the entrance and exit of the epidemic prevention area or adjusted according to customer size in a short period of time.

2Host and disinfection power part: The motor adopts a national standard full power copper three-phase asynchronous AC motor, which has the characteristics of high power and long service life. The disinfection pump adopts fully imported stainless steel corrosion-resistant high-pressure disinfection pump, imported oil seal, acid and alkali corrosion resistance, strong power, long service life and other characteristics.

3. Intelligent sensing system: It intelligently recognizes the entry and exit of vehicles, can distinguish the direction of entry and exit, and the equipment in the sensing area starts working when the vehicle enters the site. The equipment in the sensing area does not start working when the vehicle leaves the factory (referred to as one-way disinfection). The equipment in the sensing area starts when the vehicle enters the site and starts again when it leaves the factory (referred to as two-way disinfection). Magnetic induction has strong anti-interference ability against harsh environments. The equipment will not activate when personnel enter or exit the sensing area, and has basic automatic recognition capabilities.

4Automatic water filling and dispensing system: a fully imported intelligent dosing system that does not require electric drive. It can be driven by the water pressure of tap water to move the turbine, with high precision in proportioning (adjustable precision ratio of 0.2% -2%). It is made of imported composite materials that are corrosion-resistant and wear-resistant, and has a long service life. The automatic water supply system is designed with dual control of electromagnetic water supply and automatic water level controller. The tap water is connected to the equipment inlet and filtered by the water purification system inside the chassis before being transported to the medicine liquid ratio system. The evenly mixed medicine liquid will be transported to the medicine box. When the liquid level in the medicine box is lower than the design water level, the automatic water supply device and the medicine dispensing system will automatically start working. When the water level reaches the design water level, they will automatically stop and close.

5. Drinking water grade dual filtration system: The filtration system adopts 10 inch PP explosion-proof bottle dual water filtration. After purification treatment of tap water, impurities are avoided from causing damage to the equipment, which can ensure that the nozzle is not easily blocked and the system operates normally all year round.

6. Dual water level sensing: The equipment water tank is designed with dual water level sensing to avoid situations such as overflow and waste caused by the inability to detect water level in the equipment placement area due to uneven terrain.

7. Disinfection pole and pipeline: The pole is made of 304 stainless steel material, with a net height of 4 meters. The effective disinfection height for the top of the vehicle is ≥ 5 meters, far exceeding the national height limit standard. The disinfection specialized atomizing nozzle is designed with a large angle and high impact conical shape, which has strong wind resistance against the airflow during operation. The large angle design of the nozzle increases the effective working area, saves the use of disinfectant, and maximizes the disinfection effect. For vehicle chassis and tire disinfection: the upward atomization disinfection of the vehicle chassis and tires achieves a three-dimensional cross and all-round disinfection, leaving no gaps and eliminating traditional blind spots, achieving fully active disinfection.

8. Intelligent multi choice control mode: This machine integrates and provides a complete hierarchical humanized control, which can be manually turned on and off (manual control), remotely controlled (remote control), and infrared intelligent fully automatic control (fully automatic control). The three control modes can be freely selected according to the customer's on-site needs.

9. Chassis Disinfection System: Designed for upward impact atomization disinfection of vehicle chassis and tires, achieving comprehensive and three-dimensional disinfection without leaving any gaps. It can actively and thoroughly disinfect the vehicle chassis and traditional disinfection blind spots.

10. Water shortage shutdown protection function: In the event of water shortage caused by the staff's lack of knowledge or operational errors during use, the equipment will automatically shut down forcibly. When the device is replenished with water normally, the device will work normally. To avoid unnecessary damage to equipment caused by idle operation.

11. Intelligent cooling system: The control part adopts an intelligent temperature sensing intelligent cooling mode. When the temperature in the electronic control part reaches 40 degrees Celsius, the cooling system will automatically start. When the temperature is lower than the design temperature, the cooling system will automatically stop. Ensure the normal daily use and maintenance of electronic components.

12. Cast steel speed reducer: The ground spray speed reducer is configured as a pressure resistant high-end cast steel speed reducer.

13. Stainless steel pipeline protection groove: The equipment pipeline is equipped with a stainless steel high-pressure pipeline protection groove to ensure that the pipeline is damaged due to external forces.

14. Thickened luminous warning column: equipped with thickened warning columns, it provides advance guidance for vehicle entry and exit channels, and can serve as a reflective warning for vehicles entering and exiting at night.