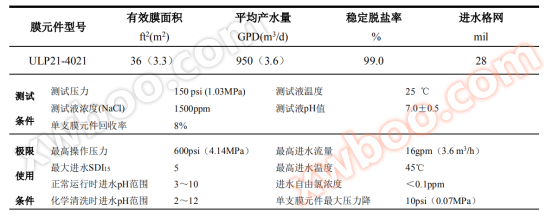

VONTRON Ultra low voltageULP21-4021RO Reverse Osmosismembrane element

Product Introduction

ULP(Ultra Low Pressure)Series ROreverse osmosis membraneIt is an ultra-low pressure aromatic polyamide composite membrane element developed by Time Walton for desalination of tap water and groundwater. It can achieve the same high water flux and desalination rate as conventional low-pressure membranes under ultra-low operating pressure conditions. Its operating pressure is about the same as the operating pressure of conventional low-pressure composite membranes2/3In order to reduce the investment cost of related equipment such as pumps, pipelines, containers, and the operating cost of reverse osmosis systems, and improve economic efficiency.

ULPSeries RO reverse osmosis membrane elements are suitable for use with salt content below 2000ppmof RODesalination treatment of water sources such as production water, groundwater, tap water, and municipal water is mainly applied to various scalesPurified waterVarious fields such as boiler feedwater, food processing, and pharmaceutical manufacturing.

Notes:

1. The data and information provided by Time Walton in this sample have been obtained through long-term experiments, and we are confident that these data and information are accurate and effective. Customers are requested to strictly follow the design, usage, and maintenance requirements of the product and keep relevant data records; Times Walton shall not be liable for any consequences arising from customers' failure to use and maintain the product in accordance with the conditions provided in this sample.

2. The water production listed in the table is the average value, and the water production of a single membrane element shall not be lower than the nominal value20%.

3. Before leaving the factory, dry membrane components do not have protective liquid, while wet membrane components are used1%Sodium bisulfite (added in winter)10%The propylene glycol antifreeze solution is stored and packaged under vacuum.

4. Dry membrane components should remain moist at all times after wetting; When wet membrane components are not used for a long time, in order to prevent the growth of microorganisms, it is recommended to use a solution containing1.0%Sodium bisulfite (food grade) protective solution (used)ROSoak membrane components in water production preparation.

5. When using membrane components for the first time, it is recommended to first rinse them with low pressure15~25Minutes (not suitable for soaking or overnight soaking), then rinse under high pressure60~90Minutes (the water production rate shall not be less than the system's designed water production rate)50%). During the initial one hour operation of the membrane element, all produced and concentrated water should be discharged.

6. It is prohibited to add any chemical agents that may affect the membrane components during storage and operation. If such chemical agents are used in violation, Time Walton will not bear any consequences arising therefrom.

7. Due to technological advancements and product updates, product information may change at any time without prior notice. Please stay tuned for updates on product information from Time Walton Company.