Product physical image

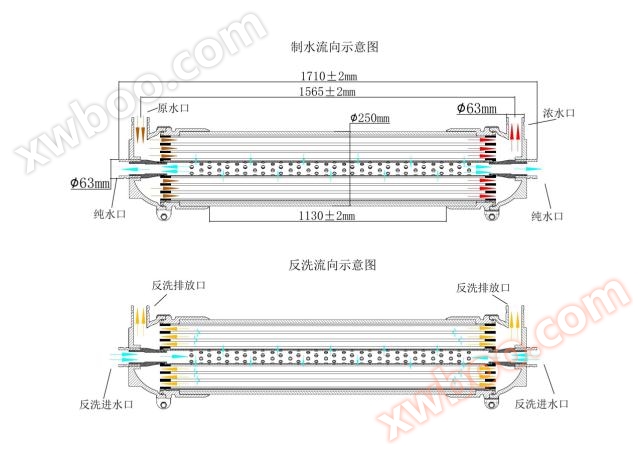

Product Dimension Drawing

1. PVC materialultrafiltration membraneComponents can remove bacteria and microorganisms, reduce turbidity and SDI, and remove colloids, large organic molecules, etc.

2. PVC ultrafiltration membrane components have high mechanical strength and good extensibility of membrane fibers, which prolong the service life of ultrafiltration membrane components.

3. The price of using ultrafiltration membrane components for PVC membrane fibers and UPVC shells is cheap.

4. PVC ultrafiltration membrane components can be applied in various fields such as drinking water purification, river water, seawater, groundwater treatment, RO pretreatment, and reclaimed water reuse treatment.

Membrane material |

modification(PVC) |

Fiber inner and outer diameter dimensions |

0.9mm/1.6mm |

Molecular weight of membrane filament cutting |

100,000Dalton(0.01micron) |

Pure water flux(0.2Mpa,25℃) |

22000L/H |

Component design water production |

1700-6000L/H |

Effective internal pressure film area |

44m² |

Shell material |

UPVC |

End sealing material |

epoxy resin |

Water inlet and outlet interface |

ø63mm(DN50) |

Terms of Use | |

preprocessing |

50-150um |

Operation mode |

Internal pressure operation |

work pressure |

0.02-0.2Mpa |

Maximum inlet pressure |

0.3MPa |

Maximum transmembrane pressure difference |

0.2MPa |

water ingressPHvalue |

2-12 |

Continuous residual chlorine concentration is tolerable |

100ppm |

Intermittent residual chlorine concentration is tolerable |

200ppm |

Operating temperature |

5℃-45℃ |

influent water quality |

Turbidity ≤15NTUWhen using other water sources such as surface water, river water, and well water, it is recommended to increase pre-treatment15Precision filters below 0um ensure that the inlet turbidity is ≤15NTU.) |

water production quality | |

*Turbidity of produced water |

< 0.1NTU |

*Pollution density index(SDI) |

< 1 |

Particles(>0.2µm) |

100% removal |

Microorganisms and pathogens |

99.99% removal |

Backwash design | |

Backwash frequency |

Once every 30-60 minutes |

Backwash pressure |

≤0.2MPa |

Backwash flow rate |

100-150L/ H. m2 |

Backwash dosing agent |

15-20PPmSodium hypochlorite |

Medication backwash frequency |

Suggest automatic dosing during each backwash |

Chemical cleaning design | |

Chemical cleaning frequency |

Once every 1-4 months |

Pickling agent |

Citric acid, oxalic acid or hydrochloric acid (prepared as a solution with pH=2) |

Alkali detergent |

0.5% NaOH+0.1% NaClO (prepared as a solution with pH=12) |

Explanation: * indicates that the raw water is tested under standard municipal tap water conditions with turbidity<5NTU | |