VIP member

Tunnel steel arch welding robot production line

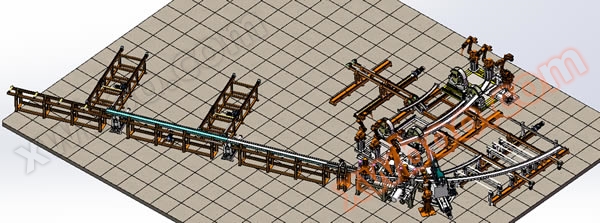

The top view is shown in the figure, and the workstation covers an area of 22000mm * 18000mm. As shown in the figure, it is the automated production p

Product details

vertical view

As shown in the figure, the workstation covers an area of 22000mm * 18000mm

As shown in the figure, the automated production process of the surrounding rock arch is a fully automated planning process from the loading of I-beam raw materials to the welding of finished products;

This workstation is suitable for 16 # -25 # I-beams, with finished product lengths ranging from 2500mm to 6000mm.

Detail drawing

The diagram shows the feeding assembly line and the handling trolley. The handling trolley transports raw materials from the assembly line to the drum conveyor line.

The diagram shows a bending machine, cutting robot, and sawing machine;

The bending machine is a single-sided bending machine, which does not affect the welding of the feeding end;

Cutting robots are used for cutting holes in I-beam arches after bending;

The sawing machine can move and rotate automatically to adapt to cutting different types of I-beams.

The diagram shows an adjustable spacing feeding conveyor line; The cut I-beams are transported by rollers to the chain conveyor line;

Adjust the position of the I-beams on the conveyor line and transport them to the welding positioner.

The diagram shows the layout of the welding section; Two feeding robots and four welding robots correspond to two cage type positioners;

The movable cage type positioner receives materials from the assembly line, and after returning to the feeding area, the feeding robot loads the materials;

After spot welding, the welding robot returns the feeding robot, and the welding robot cooperates with the positioner to weld the partial weld seam;

After welding is completed, transport to the fixed cage type positioner; After completing the remaining welding work, the second robot will automatically discharge the material onto the assembly line.

Online inquiry