product details

Product details

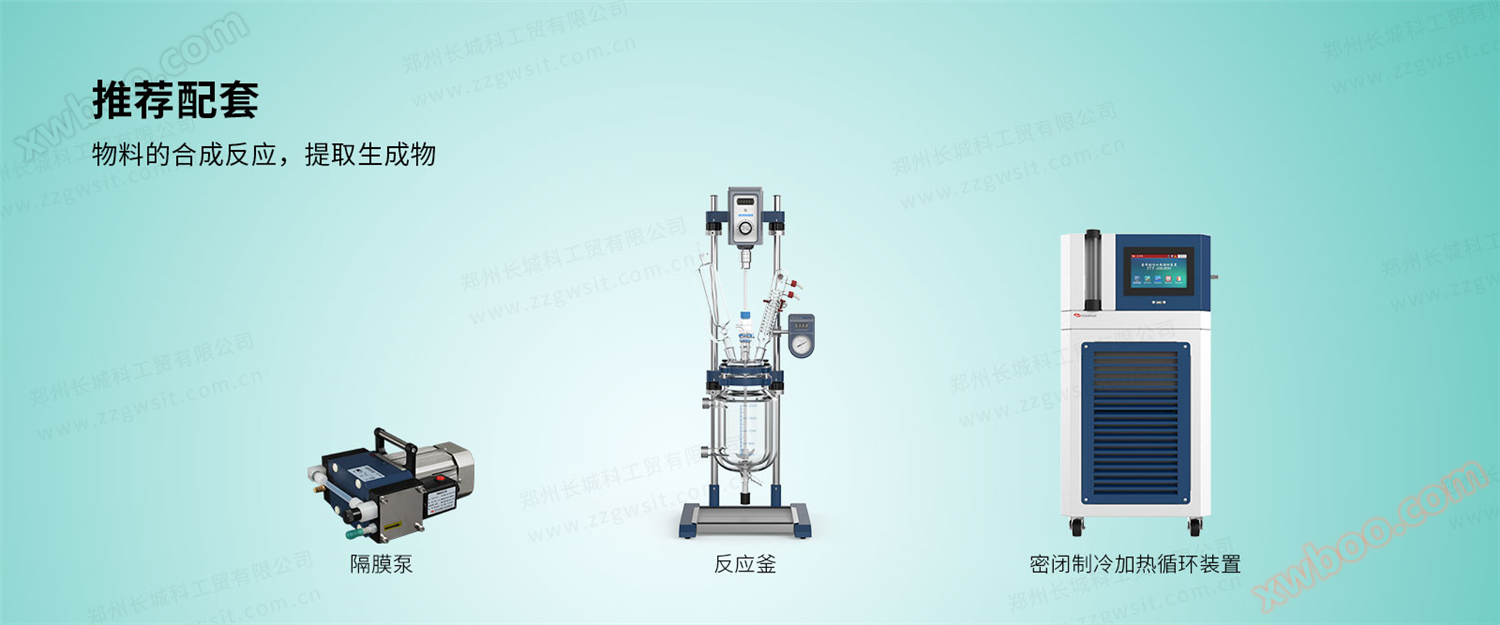

TCU temperature control unit industrial temperature control system provider

The TCU temperature control unit is used in various industries such as chemical and pharmaceutical industries when reaction kettle control is required. Multiple reaction kettle refrigeration, heating, and temperature control systems are referred to as TCUs. So, how does the TCU temperature control unit operate? How does the principle of Tcu temperature control unit come about?

Great Wall Technology Industry and Trade is a professional manufacturer of TCU temperature control units for refrigeration and heating circulation devices, also known as high and low temperature integrated machines or refrigeration and heating integrated machines. It provides high and low temperature circulating liquids for cooling or heating equipment such as reaction vessels and rotary evaporators, and provides heat or cold sources for reaction vessels through external circulation to achieve the required reaction conditions with high temperature control accuracy. Widely used in various scientific research and university laboratories such as organic synthesis, biology, pharmaceuticals, and food. There are explosion-proof types available for selection, which have the characteristics of safety, efficiency, environmental protection, and convenience.

reminder:

After the acceptance of the instrument and equipment, a one-year free warranty (excluding glass parts) and lifelong maintenance are provided.

During the warranty period of the equipment, if there are any quality problems or defects, our company will provide free replacement parts to ensure the timely and normal use of the user's equipment.

After the warranty period, if replacement parts are needed, only the cost of the parts will be charged.

4. The experimental data is sourced from the actual measurement data of the Great Wall Science and Technology Industry and Trade R&D Center.

Before putting the equipment into use, please read the product manual carefully.

| name | Closed refrigeration heating cycle device | |

| model | ZT-5-200-30H | |

| Temperature stability inside the reaction vessel(℃ ) | ±0.5 | |

| Temperature range for use(℃) | -30~ 200 | |

| ambient temperature(℃) | 5~ 35 | |

| ambient humidity | ≤70% | |

| power supply | 220V-240~, 50HZ | |

| Safety protection | Delay, overcurrent, overheating, over temperature | |

| Whole machine power(kW) | 3 | |

| display | LCD screen display, touch operation | |

| Heating wire power(kW) | 2 | |

| refrigerant | R404A | |

| Refrigeration capacity(kW) | 200℃ | 0.6 |

| 20℃ | 0.6 | |

| 0℃ | 0.5 | |

| -10℃ | 0.4 | |

| -20℃ | 0.3 | |

| -30℃ | 0.2 | |

| recirculating pump | power(W) | 180 |

| maximum flow(L/min) | 25 | |

| Maximum pressure(bar) | 1.5 | |

| External loop interface size | 1/2″ | |

| Expansion tank material | SUS304 | |

| Material of conveying pipelines and valves | SUS304 | |

| The refrigeration host occupies space(mm) | 420W×650D×860H | |

| Weight(kg ) | 106 | |