1、 Product Introduction:

QGD and QG submersible screw pumps consist of four parts: pump assembly, seal, motor, and pump casing. The pump assembly is located at the upper part of the electric pump, and its main components are the screw and rubber stator. The motor is a single-phase or three-phase asynchronous motor located at the lower part of the electric pump. Mechanical sealing is used between the pump assembly and the motor, and "O '- shaped oil resistant rubber sealing rings are used for static sealing at each fixed stop seal. The pump casing is made of stainless steel material. The design of submersible screw pump is a new type of submersible conveying tool developed from the essence of the common advantages of screw pump and submersible pump.

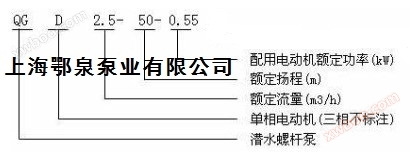

2、 Model meaning:

3、 Performance parameters:

| model | Rated flow rate (m3/h) | Rated head (m) | Rated power (kw) | Rated voltage (V) | Rated current (kg) | Net weight (kg) | Dimensions (mm) | Inner diameter of piping (mm) | Synchronous speed (r/min) | Range of head usage (m) |

| QGD1-50-0.28 | 1 | 50 | 0.28 | 220 | 2.32 | 12 | 95×540 | 25 | 2850 | 0-52 |

| QGD1.2-50-0.37S | 1.2 | 50 | 0.37 | 220 | 2.87 | 12 | 95×528 | 25 | 2850 | 0-52 |

| QGD1.2-50-0.37A | 1.2 | 50 | 0.37 | 220 | 2.87 | 13.5 | 102×540 | 25 | 2850 | 0-52 |

| QGD1.2-50-0.37C | 1.2 | 50 | 0.37 | 220 | 2.87 | 11 | 98×530 | 25 | 2850 | 0-52 |

| QGD1.8-50-0.50A | 1.8 | 50 | 0.5 | 220 | 3.79 | 14 | 102×550 | 25 | 2850 | 0-52 |

| QGD1.2-100-0.55A | 1.2 | 100 | 0.55 | 220 | 4.07 | 22 | 127×620 | 25 | 2850 | 0-105 |

| QGD2.5-50-0.55A | 2.5 | 50 | 0.55 | 220 | 4.07 | 22 | 127×615 | 38 | 2850 | 0-52 |

| QGD2.5-50-0.55 | 2.5 | 50 | 0.55 | 380 | 1.57 | 22 | 127×580 | 38 | 2850 | 0-52 |

| QGD1.8-100-0.75A | 1.8 | 100 | 0.75 | 220 | 5.24 | 24 | 127×620 | 25 | 2850 | 0-105 |

| QGD1.8-100-0.75 | 1.8 | 100 | 0.75 | 380 | 1.99 | 22 | 127×620 | 25 | 2850 | 0-105 |

| QGD2-1.5-0.8A | 2 | 105 | 0.8 | 220 | 6.4 | 25 | 127×680 | 25 | 2850 | 0-110 |

| QGD5-50-1.1 | 5 | 50 | 1.1 | 380 | 2.74 | 27 | 160×615 | 51 | 2850 | 0-52 |

| QGD5-100-2.2 | 5 | 100 | 1.2 | 380 | 5.11 | 42 | 160×910 | 51 | 2850 | 0-105 |

4、 Working conditions:

The submersible screw pump should be able to operate normally under the following conditions:

1. The medium temperature does not exceed+40 ℃;

2. The pH value of the medium is between 6.5-8.5;

3. The mass of solid acrobatics shall not exceed 3%, the particle size shall not exceed 2mm, and the fiber length shall not exceed 0.3 times the pitch of the rotor;

4. The power frequency is Hz, the voltage is single-phase AC 220V, three-phase AC 380V, and the voltage fluctuation range is 0.9-1.1 times the rated value;

5. The depth of diving underwater should not exceed 15m, but the shallowest depth should not be less than 0.5m.

5、 Purpose:

Due to the unlimited head, submersible screw pumps can work within the highest head range, with high head, high efficiency, and wide efficiency zone. Therefore, they are widely used for long-distance water irrigation, efficient oxygenation in aquaculture, deep well water lifting, urban and rural tap water boosting, mine water supply and drainage, and transportation of syrup and non corrosive chemical liquids in the food and chemical industry. Submersible screw pumps are also a type of submersible pump.