technical implementation

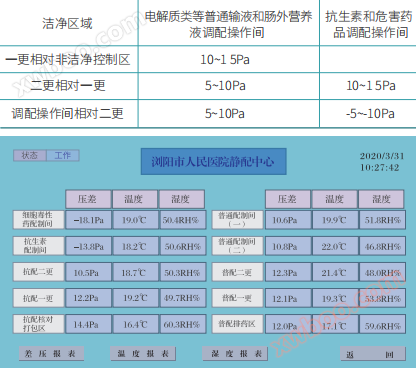

Requirements for pressure difference in clean area

System Features

Comprehensive perception

Automatically collect floating bacteria or settling bacteria sampling instruments, dust particle counters, equipment environmental noise, and illumination digital output signals around the clean environment detection indicators of the static distribution center

Fully perceive indoor environmental temperature, relative humidityCO2、Digital output signals such as PM2.5 and VOC

Real time collection of physical quantities such as clean area air exchange rate, gradient pressure difference, resistance pressure difference of high-efficiency filtration in junior high school, air valve status, access control, window magnetism, etc., automatic alarm for non-compliance

intelligent processing

Each functional area of the air supply and exhaust (return) system is treated as an independent unit, with preset target values. The opening of the air supply and exhaust valves is automatically adjusted according to changes in room pressure. When the air conditioning unit is shut down, compensation fans are activated to ensure gradient pressure difference and effective organization of airflow control

Visible, controllable, and traceable

Solve the challenges of verifying the effectiveness of airtightness, gradient pressure difference, and air exchange rate, ensuring that the WYSIWYG system, equipment, and emergency response system are in working condition at all times, and guaranteeing quality control of key links

Real time online monitoring of differential pressure, temperature, and humidity

24-hour uninterrupted monitoring of differential pressure values, temperature and humidity data in various functional areas

Real time alarm beyond preset value, can query real-time and historical data to achieve centralized control objectives

Scalable

Reserved dedicated communication interfaces for integrated data collection, reliable transmission, data storage, data processing and analysis, millisecond level control and other functions, seamlessly integrated into the intravenous medication information technology software system, fully compatible with HIS system to achieve information sharing

Simplify the process

Meet the requirements of Annex 2 Technical Specifications for Monitoring the Quality of Centralized Dispensing of Intravenous Drugs of the Guidelines, and record the data of all work and operation processes every day, so as to reduce labor intensity and work pressure

High return on investment

Reduce construction costs

Accurately monitor the difference in resistance between initial, intermediate, and high-efficiency filtration, reducing replacement and lowering costs

Accurately measure the ventilation rate of each functional area, control the gradient pressure difference of the air supply and exhaust (return) system, and achieve energy-saving effects