Smart operation and maintenance solution for new energy power plants

1、 Scheme Introduction

With the development and construction of the new energy industry, the scale of new energy power plants is becoming larger and the requirements for operational stability and reliability are increasing. Therefore, the technical requirements for operation and maintenance personnel to master are also constantly improving; Due to the variety of equipment in power plants, insufficient automation in management, and high labor intensity, a large number of operation and maintenance personnel are required to support the relevant operation and maintenance management work; In addition, due to the fact that new energy power plants are often far away from towns and transportation arteries, the difficulty of operation and inspection work has increased, making it difficult to effectively supervise on-site operations in real time, which can easily lead to safety hazards during operations.

At present, the construction of monitoring systems for new energy stations is mostly concentrated in the operational field, such as SCADA systems, online monitoring of wind turbines or photovoltaic arrays, power prediction, online monitoring of power main equipment, energy systems, etc. The interconnection between various systems is limited, and there is a lot of data that is difficult to share with each other, which cannot provide effective data support for operation and maintenance decisions.

The intelligent operation and maintenance platform for new energy power plants can strengthen the safety of new energy equipment operation and the safety of operators, ensure the stable and reliable operation of the power generation system to complete the power generation plan, increase power generation, achieve intelligent and efficient equipment digitization and refined management, and ensure the high-quality completion of various operation and maintenance operations.

2、 Program features

The intelligent operation and maintenance platform for new energy power plants has a 1+7+N intelligent operation and inspection system, including one intelligent operation and inspection full scenario solution platform, seven intelligent microservices, and N intelligent application construction ideas.

1 intelligent operation and inspection full scenario solution platform

1 intelligent operation and inspection full scenario solution platform

Realize intelligent real-time panoramic monitoring and inspection, multi-dimensional and three-dimensional management of equipment operation and maintenance, emergency response to equipment failures, equipment operation control, personnel safety control, etc.

Provide 7 intelligent microservices

Panoramic monitoring, intelligent management, remote intelligent inspection, proactive warning, equipment status assessment, intelligent decision-making, and safety operation control.

Construction ideas for N intelligent applications

Utilizing high-definition video with intelligent devices, combined with video surveillance technology, unmanned equipment, machine learning technology, mobile operation technology, Internet of Things technology, and big data analysis to achieve panoramic real-time intelligent monitoring; Based on the transformation of digital information technology, the key technology of digital visualization blockchain 5G is applied to achieve smarter, safer, and more unified management, realizing integrated digital intelligent control.

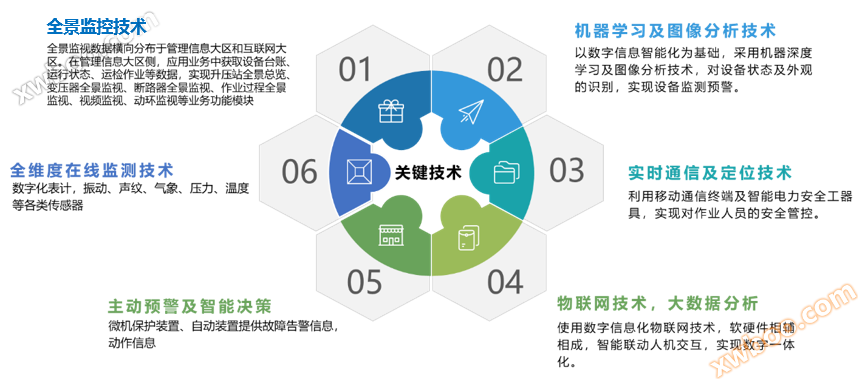

3、 Key technologies of the plan

Using video surveillance technology, machine learning technology, real-time communication and positioning technology, and the application of IoT big data analysis as the underlying business modules, we implement business functions such as panoramic overview of the field area, panoramic monitoring of transformer boosting stations, panoramic monitoring of circuit breakers, panoramic monitoring of the operation process, video monitoring, dynamic environment monitoring, and personnel safety regulations. The main key technologies are as follows:

1. Panoramic monitoring technology

Panoramic monitoring data is horizontally distributed in the management information region and the Internet region. On the management information area side, the application business obtains data such as equipment ledger, operating status, and operation inspection operations, realizing business function modules such as panoramic overview of the substation, transformer panoramic monitoring, circuit breaker panoramic monitoring, operation process panoramic monitoring, video monitoring, and dynamic environment monitoring.

Panoramic monitoring technology Panorama Stitching

2. Machine learning and image analysis techniques

Based on the intelligence of digital information, machine deep learning and image analysis technology are used to automatically determine the opening and closing status of indicator lights, instruments, pressure plates, switches, and knife switches, as well as the status of lead connectors. At the same time, based on the preset information conditions, relevant abnormalities that do not match the working status are automatically identified, such as blurred dial, damaged dial, broken insulator, silicone discoloration, damaged oil seal, suspended solids, bird nests, surface oil stains on components, ground oil stains, metal rust, etc. Equipment defects are identified, and whether there are abnormalities in the image is analyzed to achieve equipment monitoring and early warning.

Machine deep learning image parsing

3. Full dimensional online monitoring technology

The system can collect vibration, voiceprint, and other information related to the collection equipment, while also measuring meteorological, pressure, and temperature related information. Through infrared thermography, it can not only measure the temperature of the equipment, but also identify the specific parts of the relevant equipment, achieving rapid fault identification.

Infrared thermal imaging monitoring equipment

4. Internet of Things technology and big data analysis

By utilizing digital information and IoT technology, software and hardware complement each other, intelligently linking human-machine interaction, and achieving digital integration.

IoT big data analysis technology

4、 Function of the solution platform

The characteristics of the smart operation and maintenance platform for new energy power plants are: automated monitoring and perception, standardized operation processes, intensive production command, digital project control, intelligent analysis and decision-making, and visualized operation and inspection sites.

The platform system mainly consists of seven modules: panoramic monitoring, intelligent management, remote intelligent inspection, active warning, equipment status assessment, intelligent decision-making, and safety operation control.

The main functions of the system are as follows:

1. Visualized intelligent panoramic monitoring

Macro panoramic monitoring: mainly through visualization methods such as GIS maps and charts, it provides construction information for production management personnel to meet the needs of command personnel to control the overall production situation.

Microscopic panoramic monitoring: Based on digital twin technology, real-time monitoring of the operating status of main and auxiliary equipment is achieved, including operating data, status data, load data, fault defects, repair records, warning information, etc., quickly retrieving equipment and automatically locating key data in the visual model.

Visual intelligent panoramic monitoring: By monitoring data, equipment operating conditions (alarm warning), and video overview, it can achieve monitoring of photovoltaic areas, wind farms, booster stations, and other places. At the same time, it can monitor the safety and fire protection inside power plants. The system supports data fusion and realizes the display of real-life 3D models.

2. Intelligent patrol

Intelligent inspection refers to the use of big data analysis and artificial intelligence technology, utilizing high-definition video surveillance, (robots, drones,) equipment monitoring sensors and other devices to achieve high-frequency intelligent inspection at any time, real-time and efficient inspection, early detection of power generation equipment defects, and ensure equipment operation safety. Features of intelligent inspection function: remote inspection visualization, intelligent warning of equipment defects, intelligent linkage between main and auxiliary equipment, intelligent recognition of inspection defects, intelligent linkage between main and auxiliary equipment, one click sequential control of video double confirmation, etc.

3. Intelligent device management

The main functions of the intelligent device management system are to ensure standardization of the work process, accuracy and efficiency of the work, intelligence, full process tracking, filing, and review of the warehouse to achieve cost reduction and efficiency improvement. Intelligent device management includes unified management of power safety tools and spare parts, statistics of operating main equipment and spare parts, and unified management of auxiliary equipment.

4. Intelligent homework

Intelligent homework is based on electronic fences and precision positioning personnel control systems. The 3D electronic fence is equipped with intelligent wearable devices or terminals, and provides low latency and large connection channels through an indoor precision positioning gateway that integrates 5G technology. It realizes multi-level precision positioning, target tracking, trajectory query, and over limit alarm functions for homework personnel in the 3D three-dimensional space. After the system detects equipment failure warnings, it combines intelligent data-driven evaluation to provide maintenance plans, tools, and other operational processes. In high difficulty fault maintenance situations, technicians and experts are equipped with online video and voice guidance. Realize high efficiency and low cost with simple operation, no professional restrictions, and no mandatory training requirements.

5. Intelligent linkage

For the programmatic operation of new energy power generation, real-time collection of on-site videos is used to identify and analyze the positions of switches, transformers, etc. Combined with online monitoring and local monitoring system information, video linkage operation is achieved to verify the operation through video.

6. Proactive warning and intelligent decision-making

Active early warning refers to the use of intelligent inference models to obtain data on the operating status of power station equipment through SCADA, centralized monitoring of main/auxiliary equipment, intelligent inspection and other systems, and to apply them to transformers, circuit breakers, etc GIS、 Early warning and dynamic tracking monitoring of defects in main substation equipment such as isolation switches, lightning arresters, and transformers, to achieve proactive warning and defense decision-making recommendations before equipment failure. Intelligent decision-making refers to the use of intelligent reasoning technology to construct rule models and fault case libraries for transformers, reactors, circuit breakers, etc., based on the status data sensed by SCADA, centralized monitoring systems for main/auxiliary equipment, and inspection systems, as well as various equipment fault information GIS、 Quickly extract, analyze, and analyze key information of fault data for main substation equipment such as isolation switches, lightning arresters, and transformers, generate emergency response reference plans, operation and maintenance auxiliary decision-making suggestions, diagnostic testing suggestions, and maintenance auxiliary decision-making suggestions, and assist staff in handling key links after equipment failures.

7. Intelligent device evaluation

The new energy digital intelligent operation and control platform integrates full scenario digital intelligent multi-dimensional visualization monitoring and inspection technology, focusing on the operation and maintenance of main equipment, emergency handling of equipment failures, linkage of intelligent operation and maintenance, equipment control, and other closed-loop integrated full process platforms. The operation and management of main equipment and spare parts, as well as material control, are the core priorities of the owner and the station. The system has the characteristics of global, predictive, and forecasting, and can achieve comprehensive penetration and control of all equipment in the station area. Starting from the dimensions of overall equipment usage, power generation output and revenue, operational efficiency, fault life assessment, and health control, data screening is conducted.

1) Equipment Health Management

Taking intelligent big data as the technological fulcrum, health evaluation and grading of main equipment and spare parts are carried out based on data such as regular inspection, maintenance, patrol and repair benefits of equipment, achieving risk estimation and prevention, fixed-point tracking of the entire life cycle of equipment, achieving visible benefits, streamlined operation and maintenance, and controllable equipment. Transforming the traditional passive approach of only dealing with equipment damage, scrapping, and shutdown failures into a globally controllable proactive approach.

2) Equipment life assessment

Starting from equipment health management data, we aim to achieve customized life cycle profiles for different devices. With scientific data analysis results as the clear guidance for operation and inspection goals, we proactively and effectively maintain, replace, and iterate equipment, and make transformative efforts to achieve the ideal "light" operation and maintenance of no faults, no shutdowns, and no emergencies in the field. By conducting equipment health control and life assessment, we bring a qualitative leap to the new energy generation and transformation industry, enabling operations and maintenance to stay ahead of risks and failures, and enabling production benefits and efficiency costs to foresee the future.