VIP member

SH-HC31 Height Controller

The SH-HC31 flame/plasma cutting torch height controller is a mechanical lifting and electronic control integrated cutting torch height automatic cont

Product details

SH-HC31 flame/plasma cutting torch height controller

It is a mechanical lifting and electronic control integrated cutting torch height automatic control module designed specifically for portable flame/plasma cutting machines. It is simple to use, easy to debug, and cost-effective, making it an ideal matching product for welding and cutting equipment manufacturers

Height/sensitivity

Adjusting knob

HC31 adds a digital adjustment knob for height and sensitivity, which can adjust height and sensitivity statically or dynamically, and the setting results can be saved in real time The convenience is significantly improved, and the pulse adjustment knob used has a much longer service life and reliability than contact potentiometers

built-in

Stepper motor drive

The built-in stepper motor driver of SH-HC30 is a reliable driver model that our company has been selling for a long time. It can set the driving current through the controller and has more than 3 times the overload current. Its reliability and impact resistance far exceed that of simple driving chips

The SH-HC31 height controller is an upgraded version based on the HC30 controller that users have long trusted Continuing all the technological advantages of the HC30 controller, such as "control/mechanical integration", "stepper motor drive", "fully digital control", and "one click calibration", and optimizing the operation and settings

★ Industrial grade ARM processor, HC31 central processor has been upgraded from a microcontroller to a brand new ARM embedded core, with significantly improved processing speed, more powerful acceleration and deceleration algorithms, faster dynamic response, and greatly improved anti-interference ability

★ Aluminum alloy structure, HC31 main structure is manufactured using high-quality aluminum alloy drawing molds, with significantly better mechanical strength and consistency than sand mold casting

- Technical Parameter

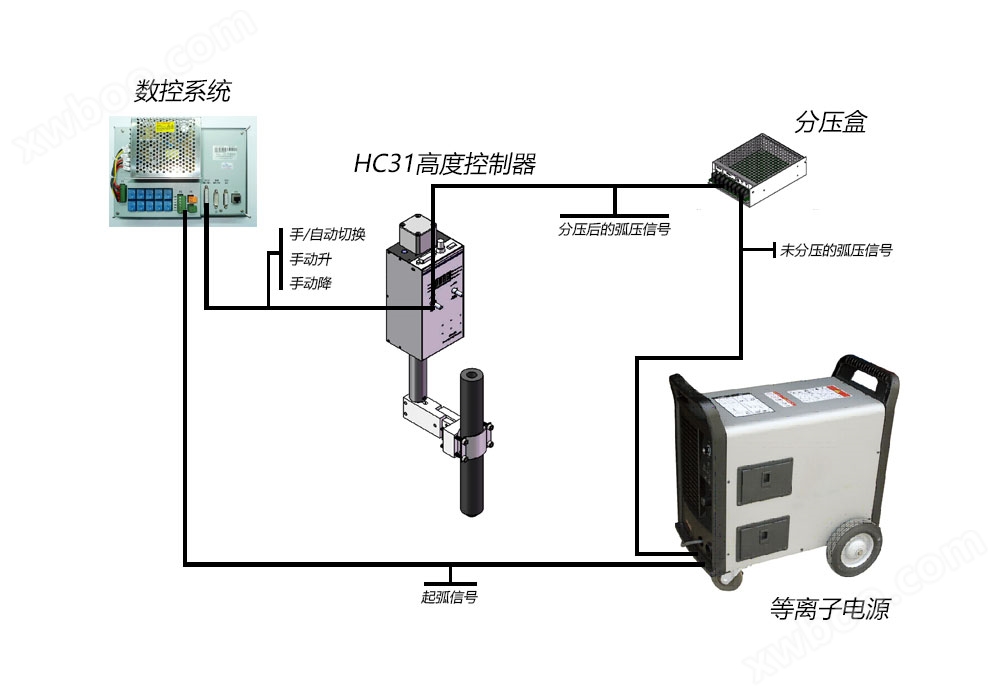

- Schematic diagram of plasma clamping installation

- connection diagram

- Rapid use process of plasma mode

- Usage Guide

| Power requirements | display | Stroke | Automatic increase control range | Automatically increase and adjust speed |

|---|---|---|---|---|

| DC24V 3A | 4-digit digital tube | 100 mm | 2~30 mm | 3000 mm/min (30 degree slope) |

| Control accuracy | Communication method | Box size | Ambient Temperature | detection system |

| Positive or negative 0.5 mm | Route 1 485 | 194.5*87*72.5 mm | -10-50 degrees Celsius | Capacitive detector, arc voltage height detector |

Schematic diagram of SH-HC31 plasma clamping installation

SH-HC31 Connection Diagram

Rapid use process of plasma mode

- SH-HC31 Flame/Plasma Torch Height Controller User Guide

Xinstarte CNC friendly reminder: The above model and parameter description are for reference only.

Online inquiry