1、 Introduction to Working Principle and Application Scope

The rotary drum dryer transports the material to be dried to the feeding end of the rotary cylinder dryer through a feeder. The material is added from the higher end, and the heat carrier can enter from the lower end in a countercurrent heat exchange form with the material; It can also be designed to allow the heat carrier and material to flow into the cylinder simultaneously. If further reduction of exhaust dust content is required, bag filter or water bath dust collector can be installed for dust removal and emission. The drying cylinder rotates, and the material moves to the lower end under the action of gravity. As the wet material moves forward inside the cylinder, it undergoes heat and mass transfer with the hot air, thus achieving the purpose of drying.

Rotary drum dryers are widely used in various industries, such as:

1. Chemical, mining, metallurgy, agriculture.

2. Dry powdered and granular materials with special requirements.

3. Such as various crystals, light calcium carbonate, activated clay, magnetic powder, graphite, inorganic mud, clay, lime slurry, ore slurry, phosphorus slag, and aluminum plant red mud.

4. Materials that require low-temperature drying and require continuous drying in large quantities.

2、 Characteristics

1. The dryer has a large processing capacity, low fuel consumption, low drying cost, and is a continuous and uninterrupted large-scale drying device.

2. Simple structure, easy operation, and easy cleaning.

3. Fewer malfunctions and lower equipment maintenance costs;

4. It has a wide range of adaptability and can be used for dehydration and drying of granular materials and materials with relatively good flowability;

5. It has high operational flexibility, strong scalability, and strong adaptability to production capacity. Even if the output increases slightly, there is no need to replace equipment.

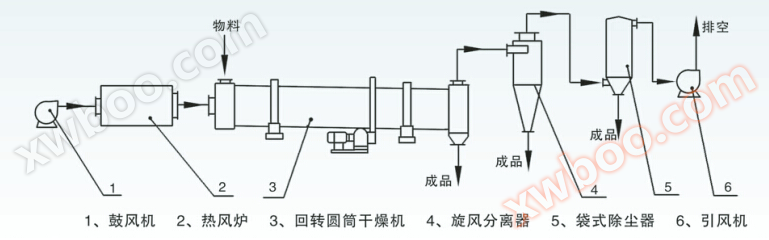

3、 Process flowchart

4、 Technical parameters (the values in the table below are for reference only during selection)