Laizhou Huayin Digital Rockwell Hardness Tester Diamond indenter Rockwell hardness block

name |

Hardness value range |

External dimensions |

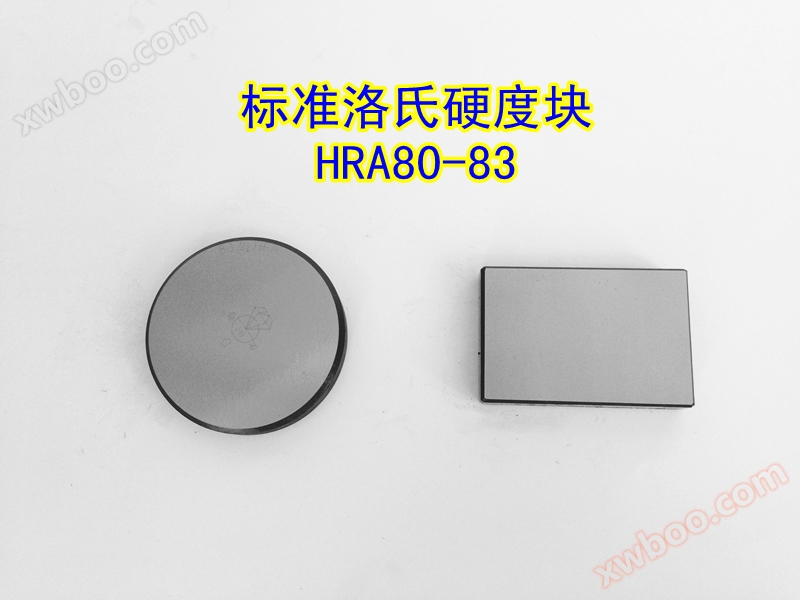

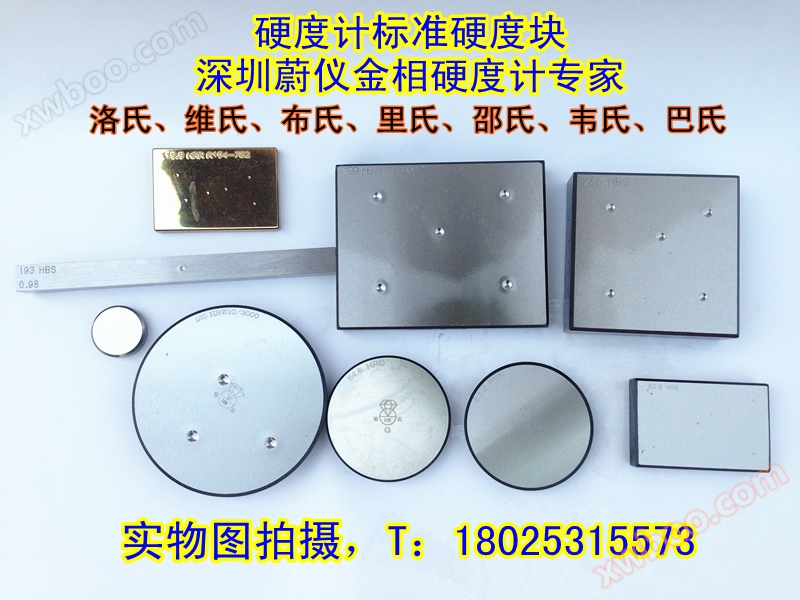

Rockwell hardness standard block |

80-88HRA |

Round with a diameter of 60 * 10mm Rectangular 60 * 40 * 10mm |

85-95HRB | ||

20-30HRC | ||

35-50HRC | ||

60-70HRC | ||

Non standard range: 50-55HRC |

Round with a diameter of 60 * 10mm |

|

Surface Rockwell hardness block |

88-92HR15N |

Round with a diameter of 60 * 10mm Rectangular 60 * 40 * 10mm |

74-82HR30N | ||

45-55HR30N | ||

45-55HR45N | ||

85-91HR15T | ||

70-80HR30T | ||

54-72HR45T | ||

Plastic Rockwell hardness block |

70-100HRE (copper) |

rectangle60*40*8mm |

50-155HRL (copper) | ||

50-155HRM (copper) | ||

50-155HRR (copper) | ||

630±40HLD | ||

530±40HLD | ||

790±40HLG |

Circular size 120 * 70mm |

|

550±50HLG |

When the tested sample is too small or the Brinell hardness (HB) is greater than 450, the Rockwell hardness measurement is used for the Rockwell hardness (HR) test. The test method is to use a diamond cone with a vertex angle of 120 degrees or a steel ball with a diameter of 1.59mm/3.18mm, and press it into the surface of the tested material under a certain load. The hardness of the material is determined by the indentation depth. According to the different hardness of experimental materials, they can be divided into three different scales to represent:

HRAIt uses a 60kg load and a diamond cone indenter to determine the hardness, and is used for materials with extremely high hardness. For example: hard alloy.

HRBThe hardness is obtained using a 100kg load and a 1.58mm diameter quenched steel ball, and is used for materials with lower hardness. For example: annealed steel, cast iron, etc.

HRCThe hardness is obtained using a 150kg load and a diamond cone indenter, and is used for materials with high hardness. For example: quenched steel, etc.

There are three different standards for Rockwell hardness: HRA, HRB, and A, B, and C in HRC. Known as Scale A, Scale B, and Scale C. The Rockwell hardness test is one of the several commonly used indentation hardness tests today. The initial pressure of the three scales is 98.07N (10Kgf), and the hardness value is calculated based on the indentation depth. The ruler A uses a ball cone diamond shaped indenter, and then applies pressure to 588.4N (60Kgf); Scale B uses a steel ball with a diameter of 1.588mm (1/16 inch) as the indenter, and then applies pressure to 1471N (150Kgf), making it suitable for detecting softer materials. The ruler C is suitable for detecting harder materials.

The most commonly used rulers are HRC, HRB, and HRF, among which the HRC ruler is used to test quenched steel, tempered steel, quenched and tempered steel, and some stainless steels. This is the most widely used hardness testing method in the metal processing industry. The HRB ruler is used to test various annealed steels, normalized steels, soft steels, some stainless steels, and harder copper alloys. The HRF ruler is used to test pure copper, softer copper alloys, and hard aluminum alloys. Although HRA rulers can also be used for most ferrous metals, their practical applications are generally limited to testing hard alloys and thin hard steel strip materials.