BYK5800 pencil hardness tester Wolf Wiburn

Purpose and Application of BYK5800 Pencil Hardness Tester:

Pencil scratches belong to a type of scratch hardness testing instrument. This is a simple and quick method to scratch the coating surface with sharp edges or other rough surfaces to test the hardness of the coating. It can also be used in the production process, such as coil coating.

Pencil hardness testing is an effective method for testing the hardness and scratch resistance of coatings.ASTM D 3363The method allows the use of a pencil with known hardness to measure by moving on the surface of the sample at a fixed angle and constant pressure.

Standard: ASTM D3363 BS 3900-E19 ECCA T ISO 15184

Design and Function of BYK5800 Pencil Hardness Tester:

The pencil hardness tester ensures that the testing is technically compliant with the Wolff Wilborn standard, ensuring that the force and angle remain constant throughout the entire testing process. The instrument is easy to operate and eliminates the possibility of pencil pressure being influenced by human factors.

BYK5800 Pencil Hardness Tester Test Procedure:

Grind out the pencil lead with a protrusion of about 5mm, hold the pencil vertically, and grind the graphite core flat and sharp with the graphite facing downwards against sandpaper (particle fineness 400).

Insert the pencil into the instrument, protrude 5mm, and then place the instrument on the surface of the template. Grasp the wheel axle with your thumb and index finger, and push the instrument on the template at a speed of approximately 10 cm/s. Choosing a pencil with appropriate hardness requires experimentation. It is recommended to start with a medium soft pencil or a medium hard pencil, and gradually find the pencil.

During the testing process, be careful not to confuse the pencil marks and penetration marks. If necessary, use a damp sponge or a soft eraser to wipe off excess line marks.

The numbers of two types of pencils are marked with pencil hardness. The hardness of a pencil, such as 2H... 3H, means that a 2H pencil can leave marks on the surface while a 3H pencil can slightly scratch the paint film. It is not recommended to use this testing method for paints with high pigment content or paints containing flake pigments.

BYK5800 pencil hardness tester ordering information:

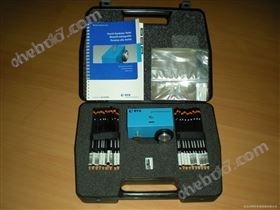

PH-5800 pencil hardness tester

The standard configuration is as follows:

Pencil hardness tester, 20 9B-9H standard pencils, 1 special pencil sharpener, 1 piece of 400 grit sandpaper, carrying case;

Ordering information:

Replace with a pencil

PH-5801 1 set of 20 standard pencils 9B-9H (20 pencils)

Pencil (pen holder with replaceable lead)

ordering information |

|

Optional spare parts and accessories |

model |

name |

quantity |

9500 |

Pencil kit |

|

5802 |

Pencil case is used for5800 |

1 |

9512 |

Replace the pencil lead,6B,9500 |

12branch1wrap |

9513 |

Replace the pencil lead,5B,9500 |

12branch1wrap |

9514 |

Replace the pencil lead,4B,9500 |

12branch1wrap |

9515 |

Replace the pencil lead,3B,9500 |

12branch1wrap |

9516 |

Replace the pencil lead,2B,9500 |

12branch1wrap |

9517 |

Replace the pencil lead,B,9500 |

12branch1wrap |

9518 |

Replace the pencil lead,HB,9500 |

12branch1wrap |

9519 |

Replace the pencil lead,F,9500 |

12branch1wrap |

9520 |

Replace the pencil lead,H,9500 |

12branch1wrap |

9521 |

Replace the pencil lead,2H,9500 |

12branch1wrap |

9522 |

Replace the pencil lead,3H,9500 |

12branch1wrap |

9523 |

Replace the pencil lead,4H,9500 |

12branch1wrap |

9524 |

Replace the pencil lead,5H,9500 |

12branch1wrap |

9525 |

Replace the pencil lead,6H,9500 |

12branch1wrap |