1.1 Function Overview

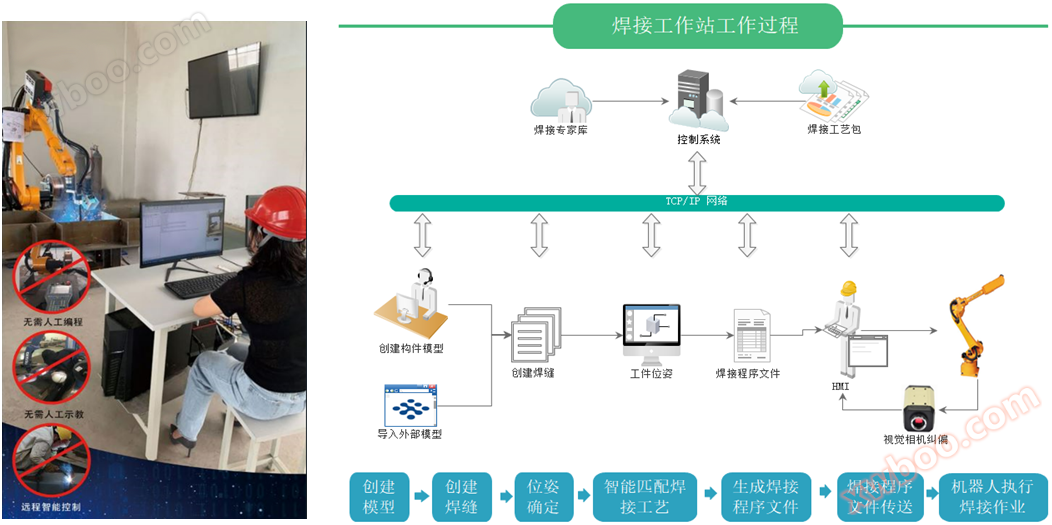

The system is a self-developed system, whose main function is to deeply integrate the welding process and import it into a 3D model. Through the visual system, the entire component weld seam is accurately positioned, and the welding program is automatically generated based on the actual contour of the position in the model.

Software deployment in On the PC system, it can be placed in any location and remotely controlled through TCP/IP protocol, allowing for direct operation of on-site equipment for welding in the office.

1.1.1 The system can meet two shifts per day(each shift8 hours of normal operation and the ability to maintain stable accuracy;

The design drawings of the workstation have undergone repeated verification and simulation design, and the design strength of each component is reliable, easy to assemble and maintain. While ensuring functionality, the appearance is also aesthetically pleasing;

All purchased parts of the workstation equipment are provided by well-known manufacturers in the industry, and the quality of all processed parts has been strictly controlled, with strength standards, superior performance, and smooth movement;

1.1.4The measurement units for the parts and instruments of the workstation equipment, as well as all drawing data, are based on the national standard sheet(GB)Standard; The design, manufacturing, and materials used for all instruments and components shall comply withISOandIECtreetopStandard or other equivalent standards;

1.1.5 Workstation components are made of high-quality materials, and the selected mechanical and electrical components are high-quality and reliable series products;

1.1.6 The front end of the robot is equipped with an anti-collision sensor, which can stop the machine in time for protection in case of collision. At the same time, an automatic cleaning gun and wire cutting system and an automatic dust removal system can be configured according to requirements;

1.1.7 Workstation visual interaction, 3D numerical simulation drive, intelligent planning of welding paths, visual scanning correction of paths, matching parameters, and automatic creation of welding programs in the process library and other intelligent welding functions.

1.1 Structure types and working mode of recommendation system

1.1.1 The H-beam crane beam and the main beam of the reinforced plate structure are operated using a one key start method with H-beam special machines, with minimal manual intervention and the highest work efficiency. Operators can operate multiple machines for work;

1.1.2 For H-shaped steel columns, roof beams, internal stiffeners and main welds of box structures, and other structural types, visual human-computer interaction is used for work, and operators can operate multiple machines;

1.1.3 Bridge slabs, large box type partitions and other structures, due to the long weld seams and small number of weld types, are welded using model driven welding, with less manual intervention and high welding efficiency. Operators can operate multiple machines for work;

1.1.4 Kotai Intelligent System is a complete system that supports various working modes mentioned above. It selects suitable modules for work according to actual usage needs to improve production efficiency.

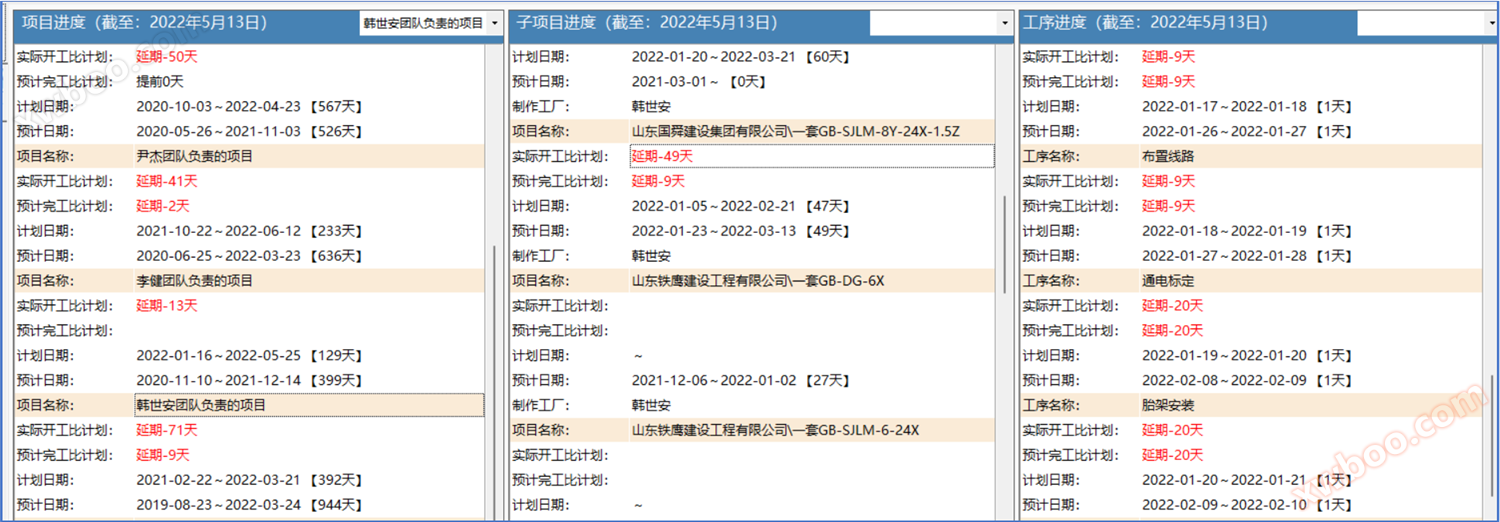

MES system

1.1.5 System features:

a) Based on Internet technology, realize the sharing of factory model data.

b) Process oriented production management can incorporate every aspect of the production process into the process flow for management

c) Integrate and improve the overall efficiency of project operation, in real-time, dynamically, and realistically, achieving full participation in management by all staff

d) Process technology, departments, groups, and permissions can be fully customized by oneself

e) Real time push of process flow information

f) Plan to automatically arrange according to production pace

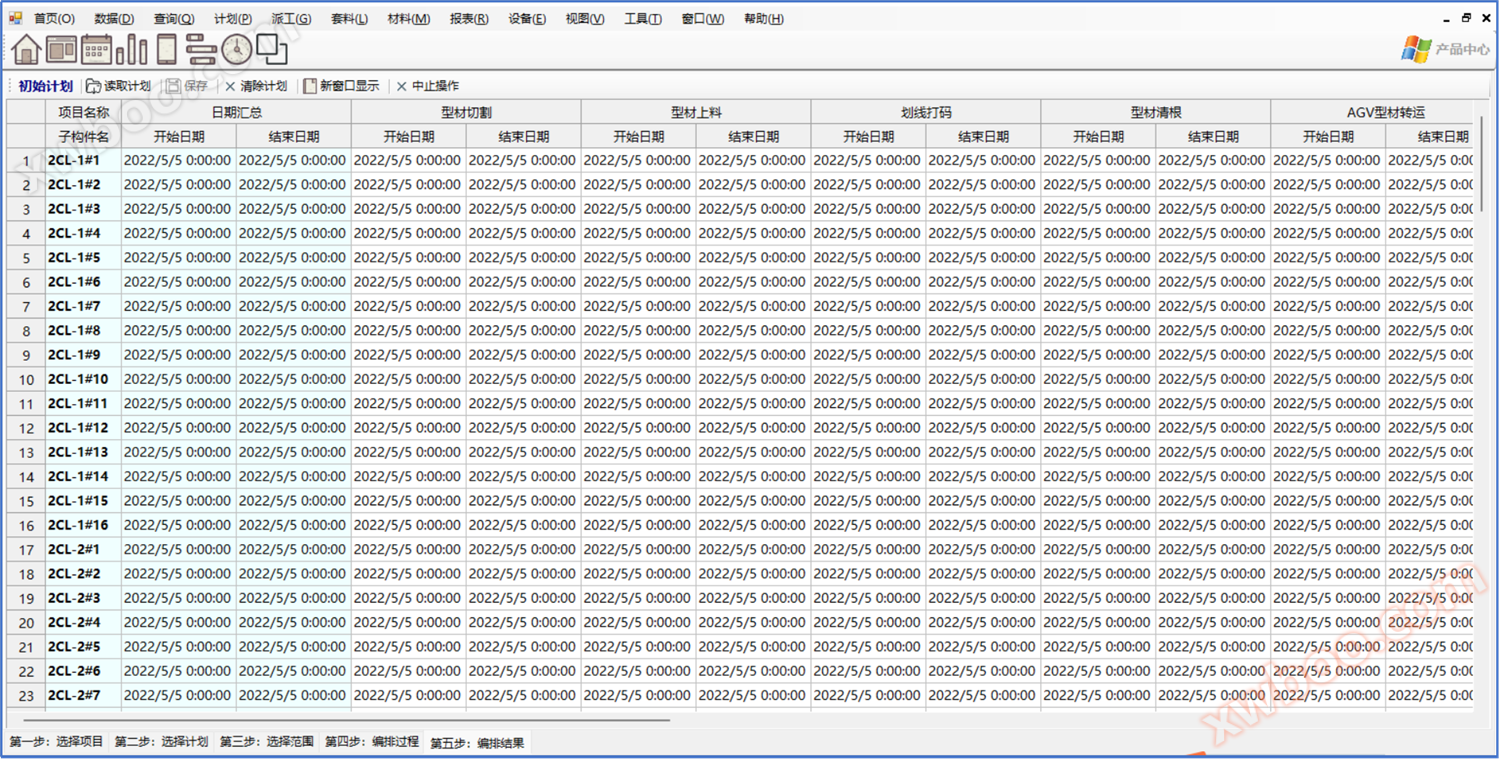

1.1.6 Planning module: Prior to the implementation of production tasks, KETI MES automatically arranges plans based on project requirements and the production pace of each workshop and workstation, generating daily work plans and supporting components for each workstation.

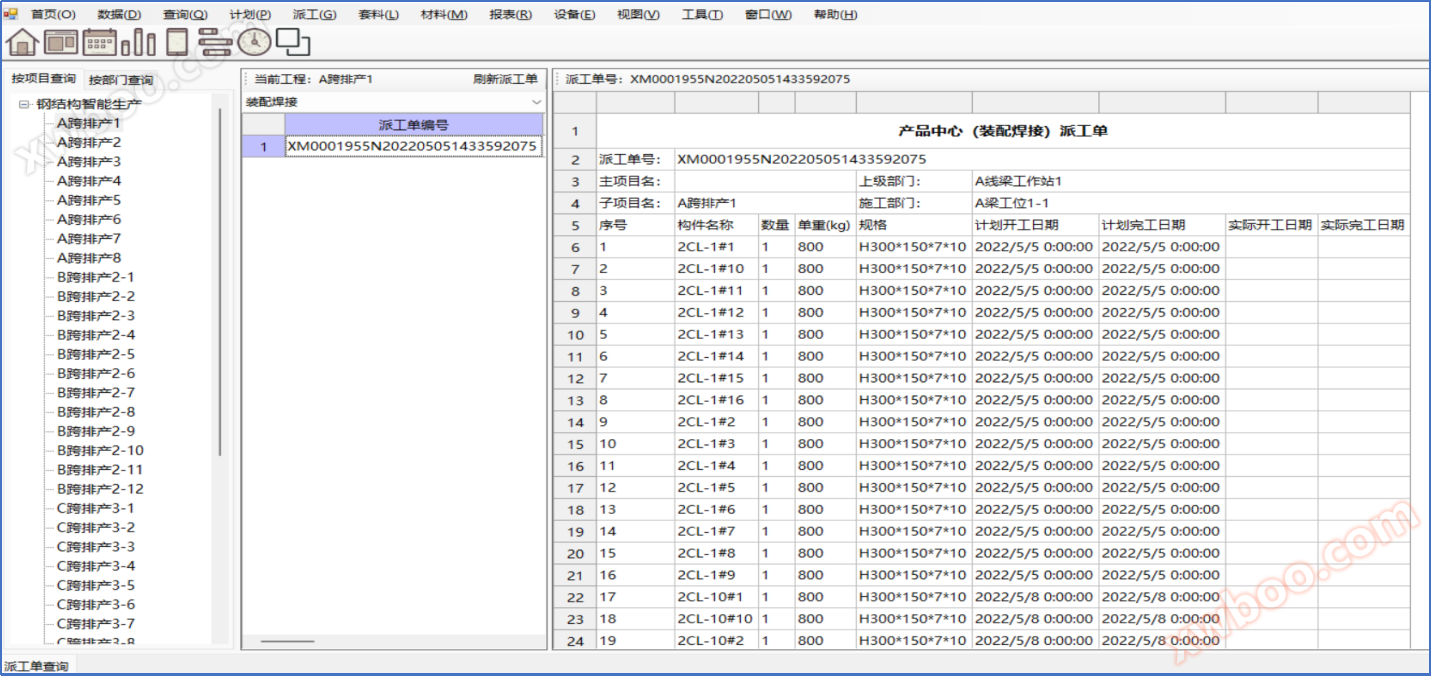

Dispatch module: Automatically arrange plans and generate specific work tasks based on project requirements and the production pace of each workshop and workstation.

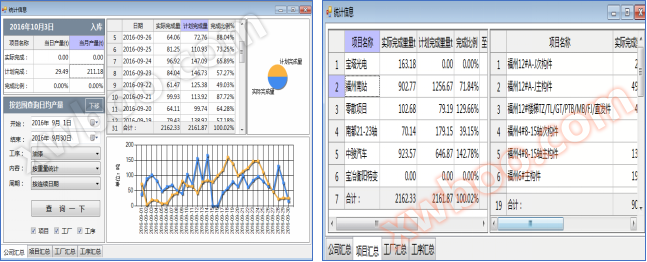

Statistics module: can query overall company data, project statistics data, factory statistics data, and process statistics data.

2. Project proposal

2.1 Product Types

2.1.1 Structural dimensions

|

Serial Number |

product |

height |

width |

Length (dual machine cooperation) |

|

1 |

h-beam |

Wing height≤0.8m |

≤1.2m |

≤12m |

|

2 |

Other products |

Vertical board height≤0.5m |

≤1.2m |

≤12m |

2.1.2 Typical product photos of users

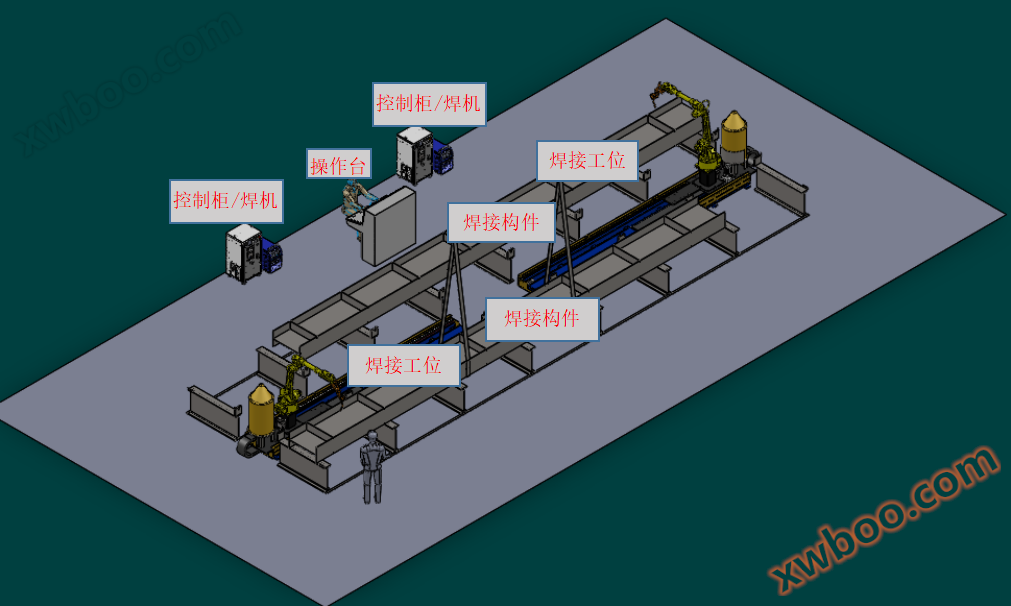

2.1 Global Layout Plan

Layout elevation view

Workflow (Model Driven Approach)

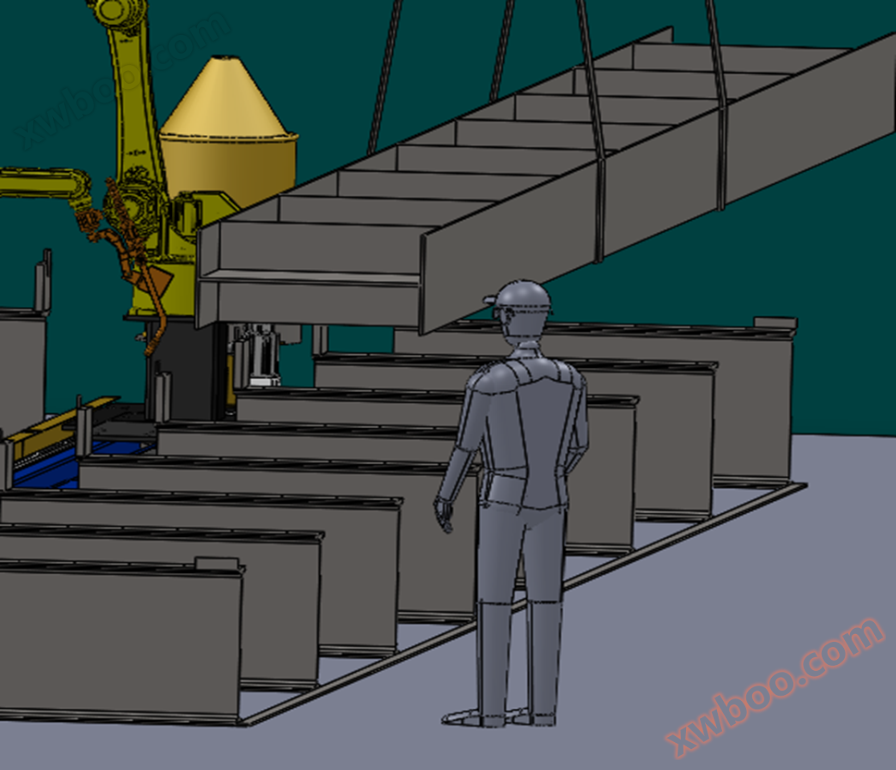

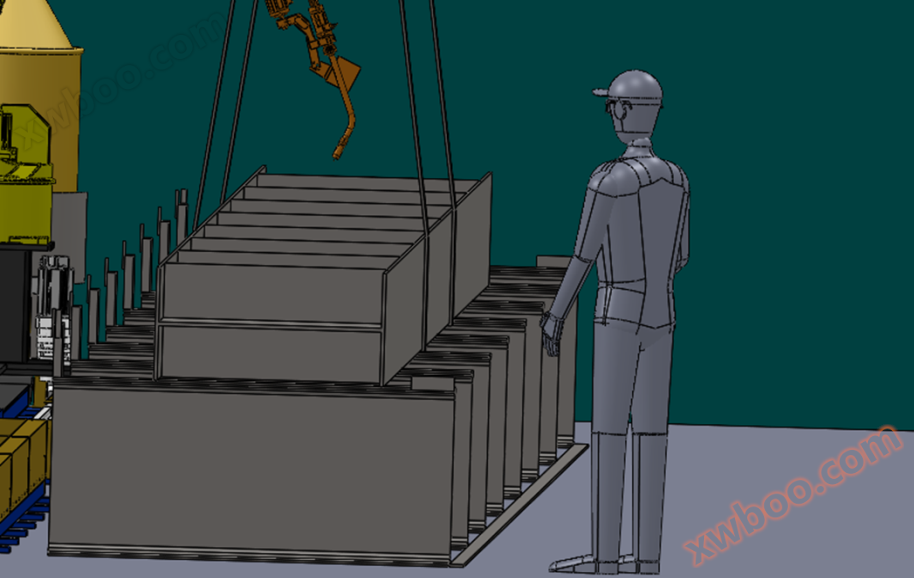

2.2.1 Manually or using a conveyor chain to transport the components to be welded to the workbench, near the positioning point P

2.2.2 (Simultaneously or in advance) The operator rotates the model uniformly according to the component number and component placement method, and creates nodes

2.2.3 If the placement deviation is too large, first use a camera to identify the component and locate point P

2.2.4If the placement position is close, the operator directly loads the model to start scanning (at this time, the operator can lift another component to the second set of equipment rack or another workstation of this equipment, and perform the above operation)

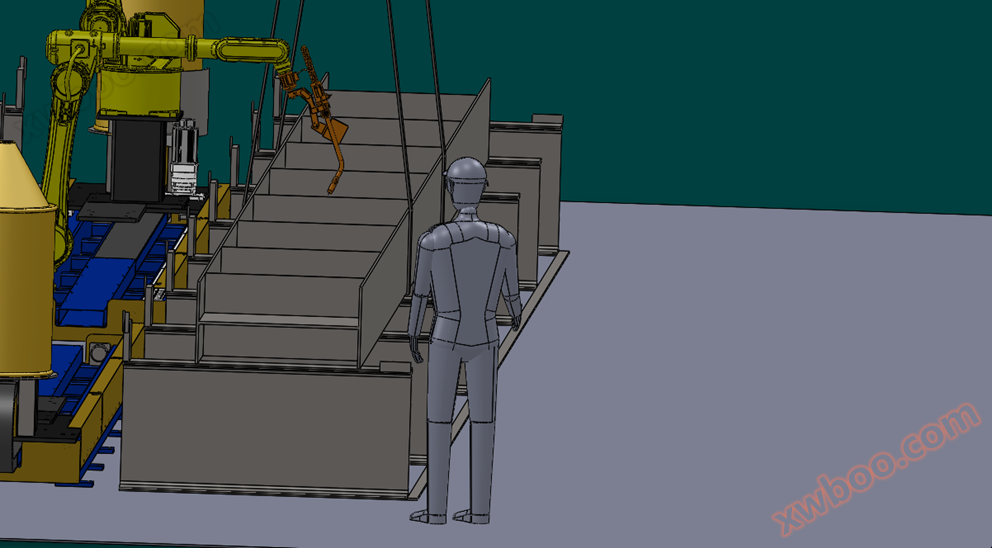

2.2.5After scanning is completed, the system starts welding

2.2.6The entire component welding is completed, and the component is transported to the subsequent work station.

2.2.7This allows operators to operate multiple sets of equipment for work

2.2.8If there is no component model, visual interaction can be used to operate the equipment welding. After the components are placed on the rack, the operator uses a camera to take photos of the parts to be welded, match the process, and start scanning welding. Compared with model driven, the workload of operators is relatively increased.