Overview of Box Packaging Machine

This machine integrates automatic box opening, pushing, folding, folding, and sealing, and is suitable for multiple varieties and specifications of paper box packaging machines. It is controlled by PLC microcomputer, with automatic alarm and fault prompt. It has the characteristics of human-machine interface control, simple operation, and convenient maintenance. Its sealing system has functions such as automatic opening, pushing, folding ears, folding ears, folding, and sealing, without the need for manual labor. All parts of the machine that come into contact with the color box are made of high-quality stainless steel and aluminum, and the surface has been polished to create a beautiful and elegant appearance that does not pollute the environment.

Packaging samples

Packaging process

① The paper box rack is used to stack paper boxes, and can hold 500-600 paper boxes at once (the self fastening bottom of the paper box will tilt). When the paper boxes are used up, they need to be manually added. The paper box rack can be adjusted according to the size of the paper boxes. If the mechanism is not adjusted properly (including the paper box rack guide rail and suction cup) and the paper box indentation is not deep enough, it will result in the inability to open the box. If the indentation is deep enough but still cannot open the box, we will add some spring plate devices based on the situation at that time. The paper box indentation is generally 0.4mm deep.

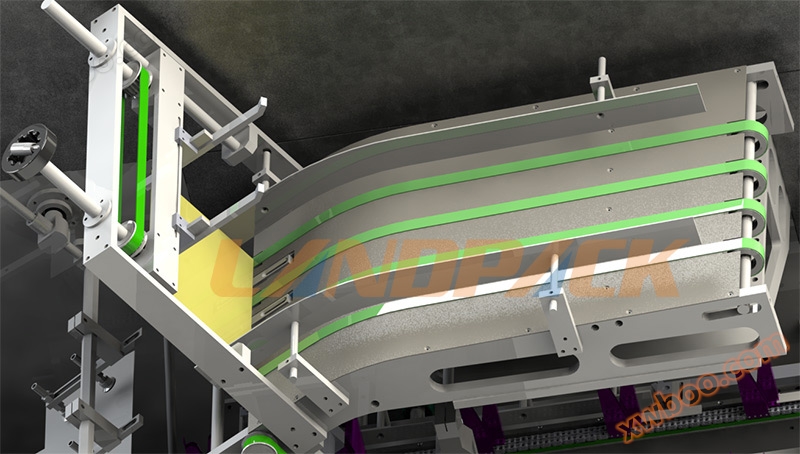

② The material conveyor belt is used to place the position of the product. The conveyor belt can be adjusted by loosening two screws and crossing them according to the size of the product to adjust the pushing grid. There are baffles on both sides of the material tray to prevent the product from being tilted. This conveyor belt can be placed manually or by machine. Use a machine to perform photoelectric positioning, and edit programs on both machines to coordinate their actions.

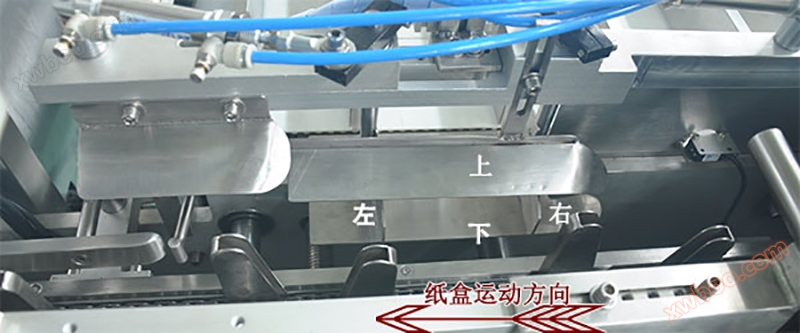

③ When a product is sensed coming from the feeding conveyor belt, the machine will automatically suck and push the material. If no product comes, the machine will not suck the box. If there is a product conveyed but no paper box, the machine will stop to provide protection. After opening the cardboard box, the cardboard box is transported to the feeding port through the cardboard box conveying mechanism chain. There are four (upper, lower, left, right) baffles to open the box, allowing the product to be smoothly pushed into the cardboard box. If there is a situation where the product cannot be pushed in, the machine will automatically stop to protect the machine and the product. It is recommended that there should be a gap of 2-3MM between the inner box or product and the outer box (length/width/height) to prevent the outer box from being too small to push in and damaging the paper box during material pushing.

④Strengthen the production efficiency, stability, and smoothness of the machine.

⑤ When the product is loaded into the paper box, the machine automatically folds the ears and folds on both sides (as shown in the picture). The position of this image is the specific part for adjusting the length/width/height of the machine. We can make a ruler at the position that needs to be adjusted according to the size of the paper box, and the machine adjuster only needs to move the relevant parts to the marked position according to the size of the paper box. If the product is compatible with larger paper boxes, the entire set of molds can be replaced!