Structure and working principle:

The main components of the water pump include the inlet section, outlet section, guide vanes, outlet section guide vanes, middle section, impeller, shaft, shaft sleeve, sealing ring, balance ring, balance disc, tail cover, etc; The rotor is composed of impellers, balance disks, and other components mounted on the shaft. Both ends of the rotor are supported by rolling bearings, which are lubricated with grease.

The working chamber of the pump is formed by the inlet section, middle section, guide vanes, outlet section guide vanes, outlet section, and tail cover. The liquid enters on one side along the axial direction, and the axial force generated during pump operation is balanced by the balance plate.

⑶ ① Shaft seal: Soft packing seal is used to prevent air infiltration and large amounts of liquid leakage. A small amount of high-pressure water flows into the packing chamber to act as a water seal to prevent impurities from entering the shaft seal; The tightness of the packing must be appropriate, so that the liquid can leak out drop by drop, thereby reducing the heat, wear, and power consumption caused by friction. Excessive liquid loss will reduce the efficiency of the water pump.

② Transmission: The pump is directly driven by the motor through an elastic coupling; From the direction of the motor, the pump rotates clockwise.

③ Bearing: Rolling bearings are used to allow the pump rotor to make slight movements.

④ Sealing ring: prevents high-pressure water from leaking back into the inlet of the water pump to reduce volume loss, and can be replaced after wear and tear.

⑤ Balance disk: located between the outlet section and the tail cover, used to balance axial forces.

⑥ Balance ring and balance sleeve: fixed on the outlet section, they together with the balance plate form a balance device.

⑦ Shaft sleeve: It serves to protect the pump shaft and fix the impeller at the two packing chambers, and can be replaced after wear.

⑷ Working principle: The pump shaft rotates under the drive of the electric motor, doing work on the liquid and increasing its energy, so that the required amount of liquid is sent from the suction tank to the required height or pressure through the pump's overcurrent component.

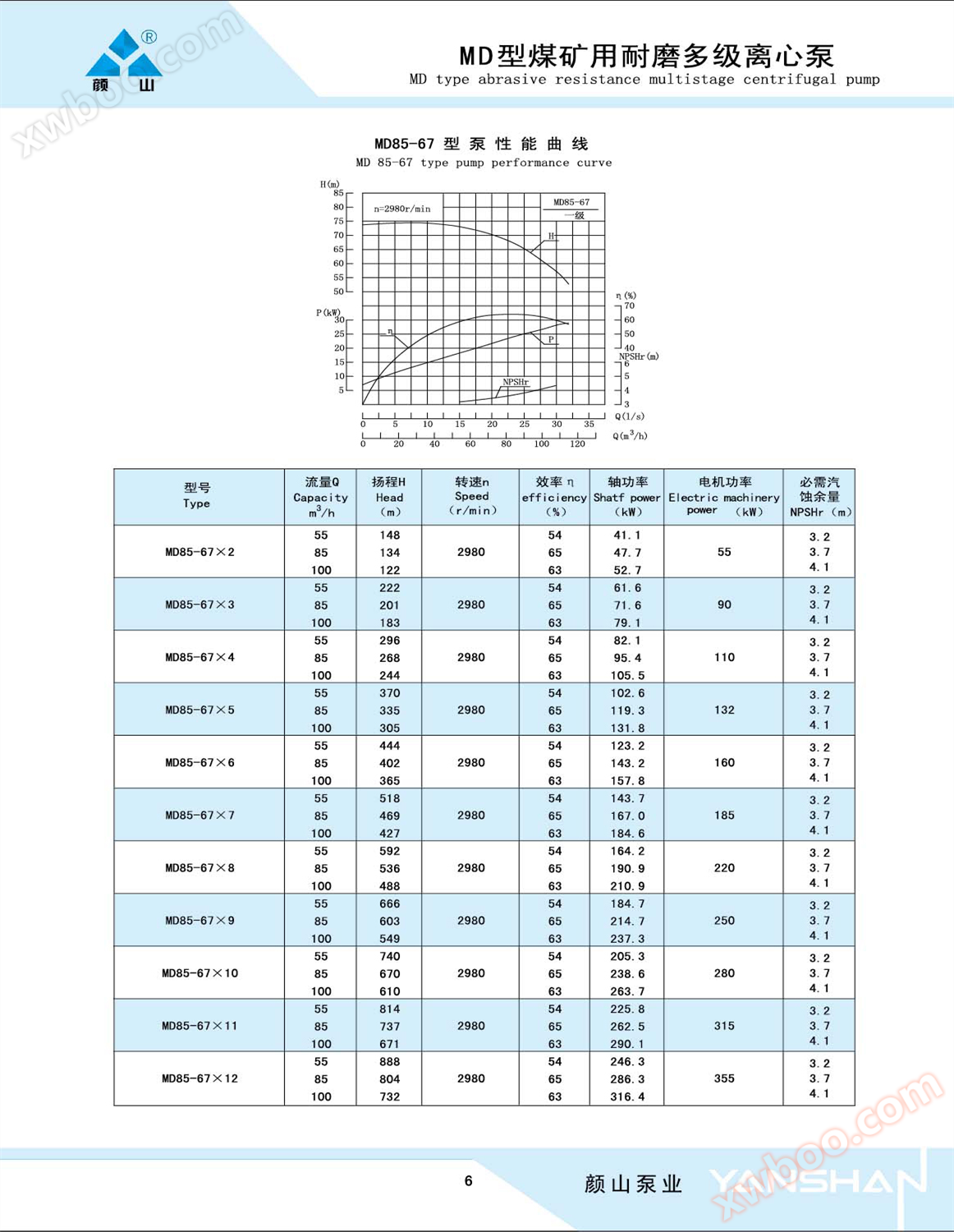

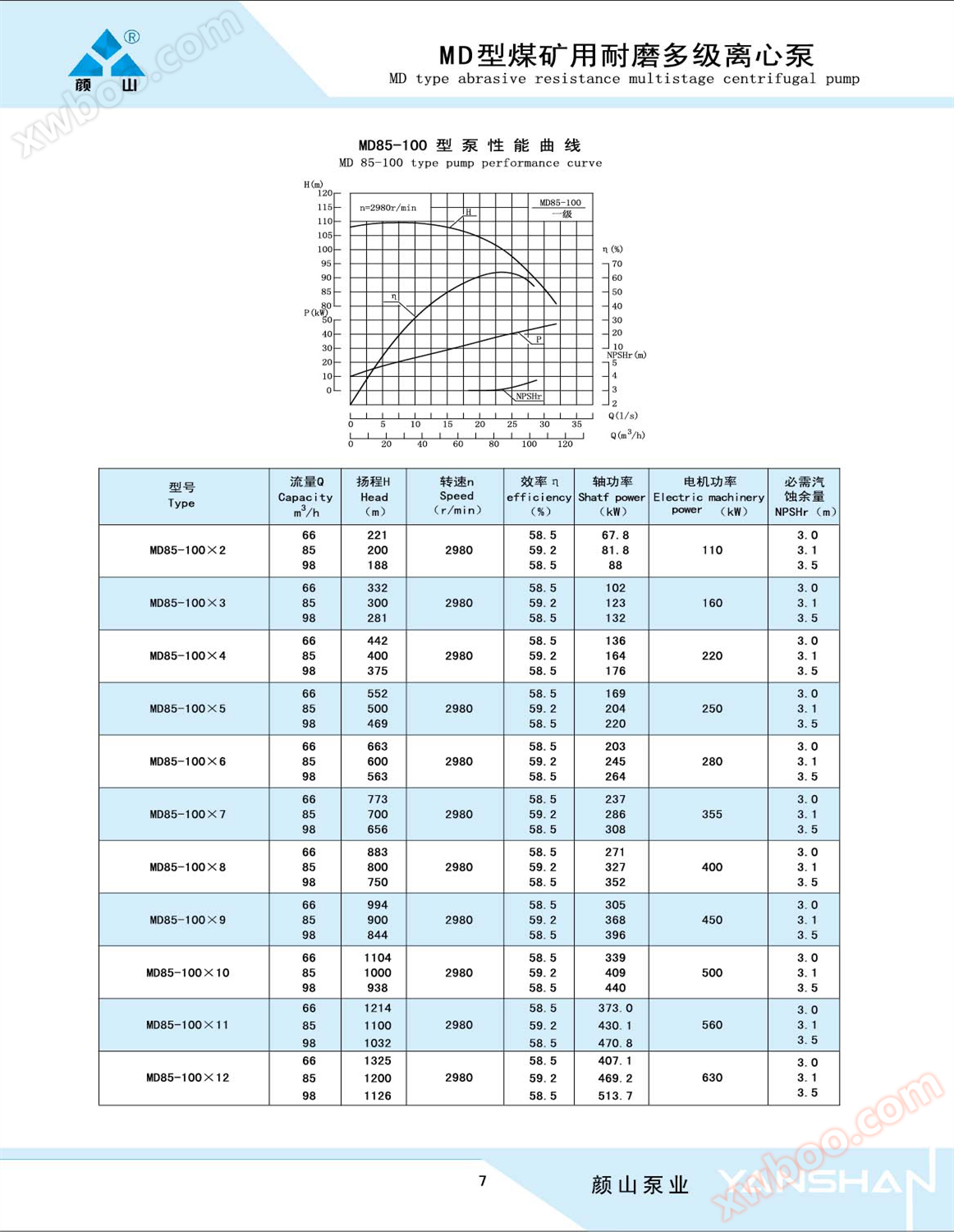

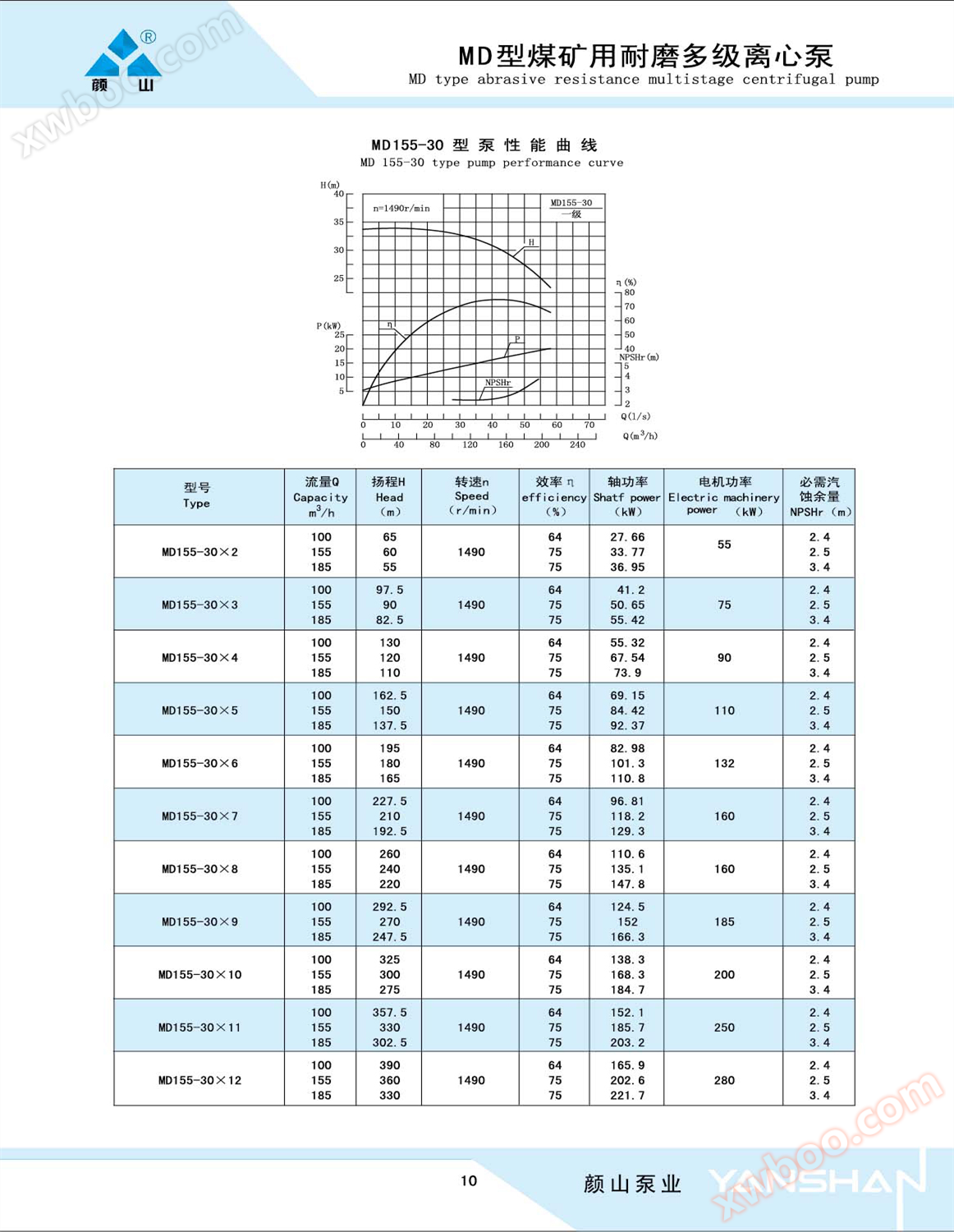

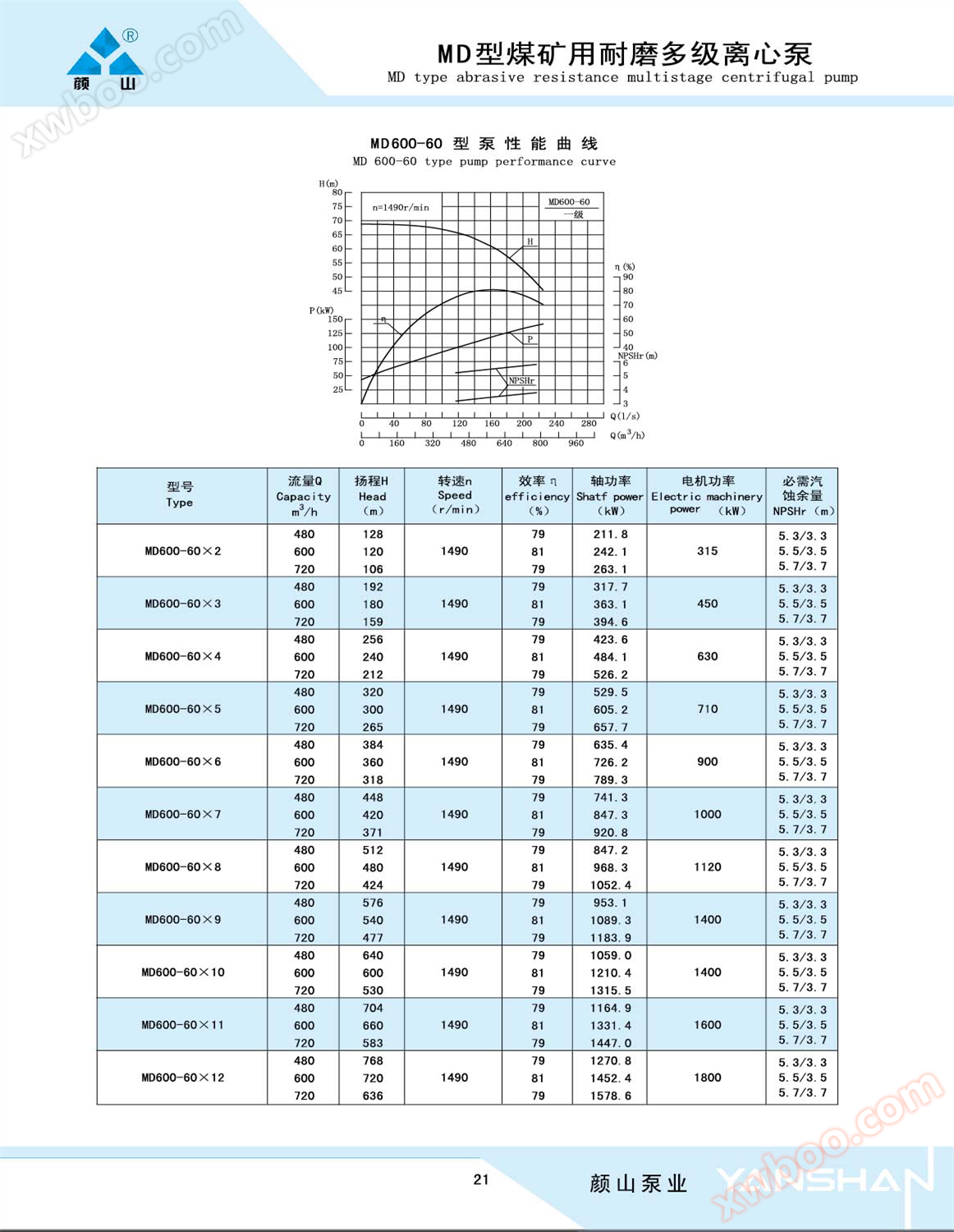

Performance parameter range:

Flow rate: 50~500m3/h

Head: 40-1000m, maximum particle size 0.5mm.

Cavitation allowance: (allowable vacuum suction height) 2.7-5m (7.5-5.2m)