|

|

Autonomous FGR technology truly low nitrogen products |

|

Beautiful appearance and long-lasting lifespan |

The Fangkuai FGR boiler perfectly combines flue gas recirculation technology with various furnace types to create truly low nitrogen products, with measured NOX<27mg/m3. |

Surface spray coating treatment, beautiful and novel; Special fin material, long lifespan |

||

| Quick and easy installation, simple maintenance in the later stage |

|

Fully intelligent Chinese operation is simple and intuitive | |

Quick installation furnace body design, no special requirements for the site, quick and easy installation; |

Real time dynamic display, real-time performance calculation, touch screen interface, multi-layer password setting, intuitive and fast operation. |

||

Performance advantages

Truly low nitrogen and environmentally friendly products that meet the emission standards of first tier cities, mainly selected for coal to gas conversion in multiple regions

Fangkuai FGR Technology,It is a technology that uses the flue gas at the outlet of the boiler to enter the boiler again as inlet air through equipment, reducing the flame temperature and thus suppressing the production of NOx. In order to perfectly apply this technology to gas boilers, the technical R&D personnel of Fangkuai Boiler conducted multiple experiments and records on the boiler structure and design, and finally optimized it continuously to control NOX emissions within the standard range.

|

Original FGR technology tested NOX<27mg/m3

|

|

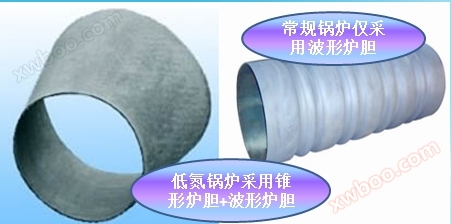

Special structural design significantly improves product performance

|

|

|

The operation interface is intuitive and simple, and the running status is clear at a glance

|

|

|

Multiple intelligent warning functions ensure safe and efficient operation

|

For detailed information about Fangkuai Boiler products, please call our customer service hotline or click on the online consultation button on the right

Customer service hotline: 400-100-9030

Technical Parameter

| Project model | WNS1.0-1.0-YQ |

WNS2.0-1.25-YQ | WNS3.0-1.25-YQ | WNS4.0-1.25-YQ | WNS6.0-1.25-YQ | WNS8.0-1.25-YQ | WNS10-1.25-YQ | WNS15-1.25-YQ | WNS20-1.25-YQ | |||

| rated evaporation | t/h | 1.0 | 2.0 | 3.0 | 4.0 | 6.0 | 8.0 | 10.0 | 15.0 | 20.0 | ||

| Rated steam pressure |

MPa | 1.0 | 1.25 |

|||||||||

| Rated steam temperature |

°C | 184 |

194 |

|||||||||

| feed water temperature | °C | 20 |

||||||||||

| Efficiency (fuel/gas) |

% | 97-100 |

||||||||||

| Fuel Consumption | diesel oil |

Kg/h | 64.4 | 128.9 | 193.3 | 257.7 | 386.6 | 515.4 | 644.3 | 966.5 | 1288.6 | |

| natural gas | Nm^3/h | 70.8 | 141.5 | 212.3 | 283 | 424.6 | 566.1 | 707.6 | 1061.4 | 1415.2 | ||

| gas | Nm^3/h | 143.7 | 287.4 | 431.2 | 574.9 | 862.3 | 1149.8 | 1437.2 | 2155.9 | 2874.5 | ||

| heavy oil | Kg/h | 67 | 134 | 200.9 | 267.9 | 401.9 | 535.8 | 669.8 | 1004.7 | 1339.6 | ||

| Power requirements | V/Hz | 380/50 |

||||||||||

| weight | t |

5.68 | 12.1 | 16 | 11.3 | 16.7 | 21.9 | 25.9 | 34.9 | 41.9 | ||

| Installation size |

Long L | mm | 3925 | 5014 | 5112 | 6110 | 6760 | 7564 | 8345 | 8500 | 9620 | |

| Wide D | mm | 2415 | 2560 | 2790 | 2800 | 2980 | 3225 | 3200 | 3500 | 5180 | ||

| High H | mm | 2263 | 3250 | 3485 | 3643 | 4075 | 4230 | 4415 | 4830 | 5272 | ||

| Transport size |

Long L | mm | 3120 | 4114 | 4380 | 4910 | 5664 | 6114 | 6900 | 6850 | 7670 | |

| Wide D | mm | 2415 | 2560 | 2200 | 2435 | 2980 | 2980 | 3200 | 3350 | 5180 | ||

| High H | mm | 2163 | 2390 | 2692 | 2770 | 3342 | 3360 | 3450 | 3930 | 4380 | ||

| Steam outlet diameter | mm | 50 | 65 | 80 | 100 | 126 | 125 | 150 | 200 | 200 | ||

| Diameter of sewage outlet | mm | 40 | 40 | 50 | 50 | 50 | 50 | 50 | 50 | 50 | ||

| Inlet diameter | mm | 25 | 40 | 40 | 40 | 40 | 40 | 50 | 50 | 65 | ||

| chimney | mm |

300 | 350 | 450 | 450 | 550 | 550 | 700 | 900 | 900 | ||

| electric power | fuel | kw | 3.55 | 8.9 | 14 | 16 | 18 | 29 | 34 | 69 | 79 | |

| gas | kw |

3.2 | 8.5 | 13 | 16 | 18 | 29 | 34 | 61 | 67 | ||

| remarks |

Horizontal triple return | |||||||||||

The above parameters do not have contractual nature and should be subject to the specific terms of the contract

The fuel consumption is the value after installing the condenser; Fuel calorific value: heavy oil 9860kcal/kg, diesel 10250kcal/kg, natural gas 9140kcal/Nm3, liquefied petroleum gas 24998kcal/Nm3, city gas 4500kcal/Nm3; Due to the continuous improvement of technology, any changes will not be notified; Please request detailed parameters from Fangkuai headquarters.