VIP member

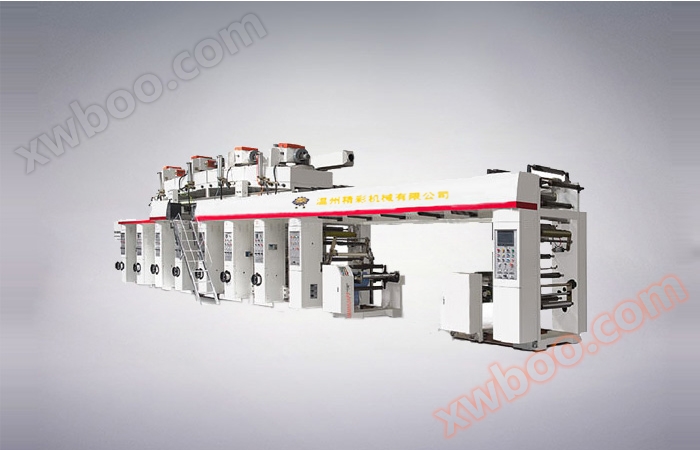

JSASY-B Type Heat Transfer Printing Machine

JSASY-B Type Heat Transfer Printing Machine

Product details

JSASY-B Type Heat Transfer Printing Machine

Purpose:

This machine is a specialized equipment for gravure printing, lamination, coating, and slitting of roll shaped materials such as BOPP, PET, PVC, PE, aluminum foil, paper, non-woven fabric, glass paper, and thin leather.

Features:

1. Each control unit of the automatic color matching system is independently equipped with a microprocessor, which can quickly and accurately correct color deviation.

2. Main transmission mechanism: The main transmission adopts Japanese Yaskawa vector frequency converter to control the vector motor, with variable frequency speed regulation, and drives each group of printing plates.

3. Shaftless plate installation mechanism: The plate is installed using a cylinder, which pulls the core shaft for installation, and the horizontal adjustment is moved by a screw.

Feature: Reduce version change time.

4. Pneumatic ink scraper: The scraper can be adjusted up, down, and at any angle, with a single cylinder for hanging pressure and a synchronous motor for rotating the cam for lateral movement.

Feature: Extended version of longevity noodles.

5. Embossing lifting mechanism: Embossing adopts dual cylinder boosting and slider self-locking positioning, which provides protection against cylinder leakage and cylinder dropping during shutdown.

Features: Ensure even pressure and color difference.

6. Color matching mechanism: computer-controlled synchronous motor is used to automatically match colors through deceleration transmission ball screw adjustment.

Features: Rotating lubrication, high color matching accuracy.

7. Material receiving and discharging mechanism: adopts dual station, non-stop material receiving.

8. The tension of material collection and discharge, as well as the traction tension of material collection and discharge, are controlled by variable frequency vector control for linear speed.

Features: Accelerated color matching stability, no horizontal plate running, can save materials, ink, solvents, and energy for large-scale printing. In high-speed fully automatic material exchange, the maximum waste of material exchange is about 10 meters, and ink, solvent, and energy are saved by about 20%, greatly reducing the cost of finished products.

9. Drying: Electric heating tubes are distributed at the blowing ports of each oven for heating, forming an air flow thermal cycle inside the oven, and the temperature is controlled by an intelligent temperature controller. Recycling and reusing air.

Characteristic: Save electricity.

10. Cooling structure: The oven adopts a centrifugal blowing and suction method, and the return roller is cooled with water.

Characteristic: The material cools quickly.

2. Main transmission mechanism: The main transmission adopts Japanese Yaskawa vector frequency converter to control the vector motor, with variable frequency speed regulation, and drives each group of printing plates.

3. Shaftless plate installation mechanism: The plate is installed using a cylinder, which pulls the core shaft for installation, and the horizontal adjustment is moved by a screw.

Feature: Reduce version change time.

4. Pneumatic ink scraper: The scraper can be adjusted up, down, and at any angle, with a single cylinder for hanging pressure and a synchronous motor for rotating the cam for lateral movement.

Feature: Extended version of longevity noodles.

5. Embossing lifting mechanism: Embossing adopts dual cylinder boosting and slider self-locking positioning, which provides protection against cylinder leakage and cylinder dropping during shutdown.

Features: Ensure even pressure and color difference.

6. Color matching mechanism: computer-controlled synchronous motor is used to automatically match colors through deceleration transmission ball screw adjustment.

Features: Rotating lubrication, high color matching accuracy.

7. Material receiving and discharging mechanism: adopts dual station, non-stop material receiving.

8. The tension of material collection and discharge, as well as the traction tension of material collection and discharge, are controlled by variable frequency vector control for linear speed.

Features: Accelerated color matching stability, no horizontal plate running, can save materials, ink, solvents, and energy for large-scale printing. In high-speed fully automatic material exchange, the maximum waste of material exchange is about 10 meters, and ink, solvent, and energy are saved by about 20%, greatly reducing the cost of finished products.

9. Drying: Electric heating tubes are distributed at the blowing ports of each oven for heating, forming an air flow thermal cycle inside the oven, and the temperature is controlled by an intelligent temperature controller. Recycling and reusing air.

Characteristic: Save electricity.

10. Cooling structure: The oven adopts a centrifugal blowing and suction method, and the return roller is cooled with water.

Characteristic: The material cools quickly.

Main technical parameters:

| model |

JSASY-B-1050 |

JSASY-B-850 |

JSASY-B-650 |

| Printing diameter | Ф120mm~Ф320mm | Ф120mm~Ф320mm | Ф120mm~Ф320mm |

| Printing width | 1000 | 800 | 600 |

| Unwinding diameter | Ф600mm | Ф600mm | Ф600mm |

| Roll diameter | Ф600mm | Ф600mm | Ф600mm |

| mechanical speed | 10-150m/min | 10-150m/min | 10-150m/min |

| printing speed | 10-130m/min | 10-130m/min | 10-130m/min |

| Overprint accuracy | ≤0.1mm | ≤0.1mm | ≤0.1mm |

| drying method | Electric heating (oil heating or steam) | Electric heating (oil heating or steam) | Electric heating (oil heating or steam) |

| Total machine power | 120KW | 120KW | 120KW |

| machine weight | 40000KG | 39000KG | 38000KG |

| Overall dimensions | 18690×3400×3400(mm) | 18690×3200×2500(mm) | 18690×3000×3400(mm) |

Online inquiry