Due to the large amount of high-pressure water used for cooling in high-speed wire production lines, the cooling water inevitably enters the lubrication system of the rolling mill. This requires timely measures to be taken when cooling water is detected to reduce the possibility of floating liquid formation. When the water content of the oil film bearing oil used in high-speed wire mills exceeds 0.5%, the probability of bearing failure increases significantly. If the water content exceeds 1%, rolling bearing failure is highly likely to occur in the short term.

At present, the lubrication system of high-speed wire rolling mills is a centralized thin oil lubrication system, which mostly adopts a dual oil tank configuration. It is supplied with oil by a lubrication pump station and flows through the oil film bearings of the rolling mill before passing through the frame return oil pipe of the rolling mill and sharing the return oil pipe to the oil tank. This requires monitoring the lubrication and oil tank of each rolling mill, promptly identifying which rolling mill is leaking water and whether the water content in the main oil tank exceeds the limit, in order to repair or replace the backup oil tank and activate the oil tank dehydration device in a timely manner.

The JCW-1 rolling mill lubricating oil moisture content online monitoring system can simultaneously connect multiple moisture sensors; Equipped with on-site industrial computer display and calibration functions; Capable of remote data transmission; Electrical protection design for harsh working conditions, intelligent temperature compensation, and online calibration; Expandable multiple oil sensors; Supports RS485, 4-20mA, Bluetooth, NB-IOT, LORA, etc.

1.1 Schematic diagram of JCW-1 rolling mill lubricating oil moisture content online monitoring system

1.2 Sensor selection

This scheme adopts the JCW-1624 oil moisture online monitoring sensor independently developed and produced by Beijing Jiecheng IoT Technology Co., Ltd. JCW-1624 Oil Moisture Online Monitoring Sensor is a new type of online oil moisture content detection sensor based on dielectric constant method. The sensor adopts a unique double symmetrical electrode structure, high-precision dielectric constant detection technology, combined with temperature compensation technology and rich experience in moisture calibration, to accurately obtain changes in water content in oil. It can be widely used in online monitoring of moisture content of crude oil and lubricating oil in oil exploitation, smelting, power, steel, chemical industry, marine gearbox and other fields.

JCW-1624 Sensor Dimensional Drawing

Physical picture of JCW-1624 sensor

main features

Accurately measure the moisture content in oil (ppm)

Measuring moisture content range: 0~15%

Comes with calibration software, making it convenient for customers to calibrate and calibrate

Direct insertion structure, compact and easy to install

Measure various oil samples such as lubricating oil, hydraulic oil, insulation oil, etc

Built in temperature sensor for high-precision temperature compensation

Long term stable operation in harsh environments

Optional on-site display instrument and LCD control display screen

Technical parameters of sensors

Range (absolute accuracy): 0-7% (± 0.1%), 5% to the inversion point (± 2%), 0-100%

Temperature stability: 0.01% water/℃

Resolution: 100ppm

Supply voltage: 12VDC~30VDC (typical value 24VDC)

Fluid temperature: 5~+95 ℃; Compensation temperature range: 5~+95℃ ;

Circuit operating temperature:- 40~+85℃

Pressure range: 0-3Mpa

Output: RS485(MODBUS-RTU); 4~20mA;

Temperature sensor: Pt1000 platinum RTD

Temperature resolution: 0.4 ℃

Material: 304 stainless steel

Mechanical interface: M24*1.5、 Flanges, flow-through type;

Protection level: IP67

Mechanical installation of sensors

This analyzer is generally installed vertically, and the oil flows from bottom to top, which can prevent the accumulation of bubbles in the measurement area. It is necessary to maintain an appropriate flow rate to prevent water separation within the measurement area. For crude oil products, the minimum flow rate is 4 USGPM. If it is a high wax oil product, the flow rate should be at least 20 GPM to prevent wax deposition in the sensor.

The installation of sensors can choose to use large-diameter sensors in series with the main pipeline, or small-diameter sensors in parallel with the main pipeline. It is necessary to ensure that the sample flow truly reflects the true situation of the main pipeline fluid.

Schematic diagram of installation method for moisture sensor pipeline (recommended)

1.3 Intelligent Terminal Protocol Converter

Product Name: Intelligent Terminal Protocol Converter Product Model: JCS-1000 Function Description: Industrial equipment networking, protocol conversion, data acquisition, etc. Applicable occasions: power distribution automation, factory automation, Internet of Things, smart homes, photovoltaic power generation, intelligent security, energy management, etc. Interface description: 1x10M/100M port, 2xRS232/RS485 composite serial port, 9-36VDC power input, port serial port optical transceiver

Typical applications:distribution automation

Application Description of Distribution Network Automation:

The V-protocol converter converts the protocol of the protection device in the pole mounted switch to the IEC60870-5-101 (or 104) protocol

The IEC60870-5-101 protocol supports balanced Southern Network, unbalanced State Grid, and DTU access verification

The IEC60870-5-104 protocol supports main stations from manufacturers such as NARI, Shandong Jicheng, and Sifang

1.4 Introduction to System Cloud Platform and Mobile APP

Beijing Jiecheng IoT Technology Co., Ltd.'s system cloud platform provides digital solutions for device end-users based on cloud architecture, industrial IoT, and big data technology, covering the following functional modules

Real time monitoring of equipment status and historical data recording

- Equipment alarm monitoring

- Equipment maintenance management

The goal is to help end users improve their equipment asset operation and maintenance management level, enhance equipment performance, improve production efficiency, and save costs.

1.4.1 Exclusive website, data isolation

Provide independent accounts for each end user

Data isolation, secure and reliable

• Comprehensive user role and permission management

1.4.2 Powerful functionality and clear interface

• Provide real-time and historical data

• Provide current and historical alarm information

• Manage equipment maintenance

• The backend provides complete and reliable user role and permission management functions

Remote monitoring platform (customizable)

Remote monitoring platform (customizable)

1.4.3 PC Web Interface

1.4.3.1 Multi point map navigation, making industrial control and alarm clear at a glance

• Display the alarm status of each device

• Display of key indicator numbers

Cloud platform interface (customizable)

Cloud platform interface (customizable)

1.4.3.2 APP - ALPHA System

APP-ALPHA is a system that subverts traditional server based data

ALPHA directly reads data that is valid and reflects the actual situation on site

• Equipped with a window for on-site input of equipment operating condition information

Effective path for establishing diagnostic models

• Diagnostic experts' judgment criteria

• Database of inspection personnel for efficient inspection tracking

Pad in hand, device health history traceable

• Can be used to calibrate sensors connected to the system

APP-ALPHA system interface (customizable)

2、 Case Study of Online Monitoring of Lubricating Oil Moisture Content in Rolling Mill of a Special Steel Group Company in Shandong Province

Steel production line

Lubrication pump station

Oil return pipe opening

Welding installation sensor interface

Welding installation sensor interface JCW-1624 oil moisture sensor installed on the return pipe

JCW-1624 oil moisture sensor installed on the return pipe JCW-1624 oil moisture sensor installed on the pre precision rolling oil outlet

JCW-1624 oil moisture sensor installed on the pre precision rolling oil outlet Electrical control box for online monitoring system of oil water content

Electrical control box for online monitoring system of oil water content Internal layout of electrical control box for online monitoring system of oil water content

Internal layout of electrical control box for online monitoring system of oil water content Electrical cabinet of lubrication pump station in steel enterprise

Electrical cabinet of lubrication pump station in steel enterprise

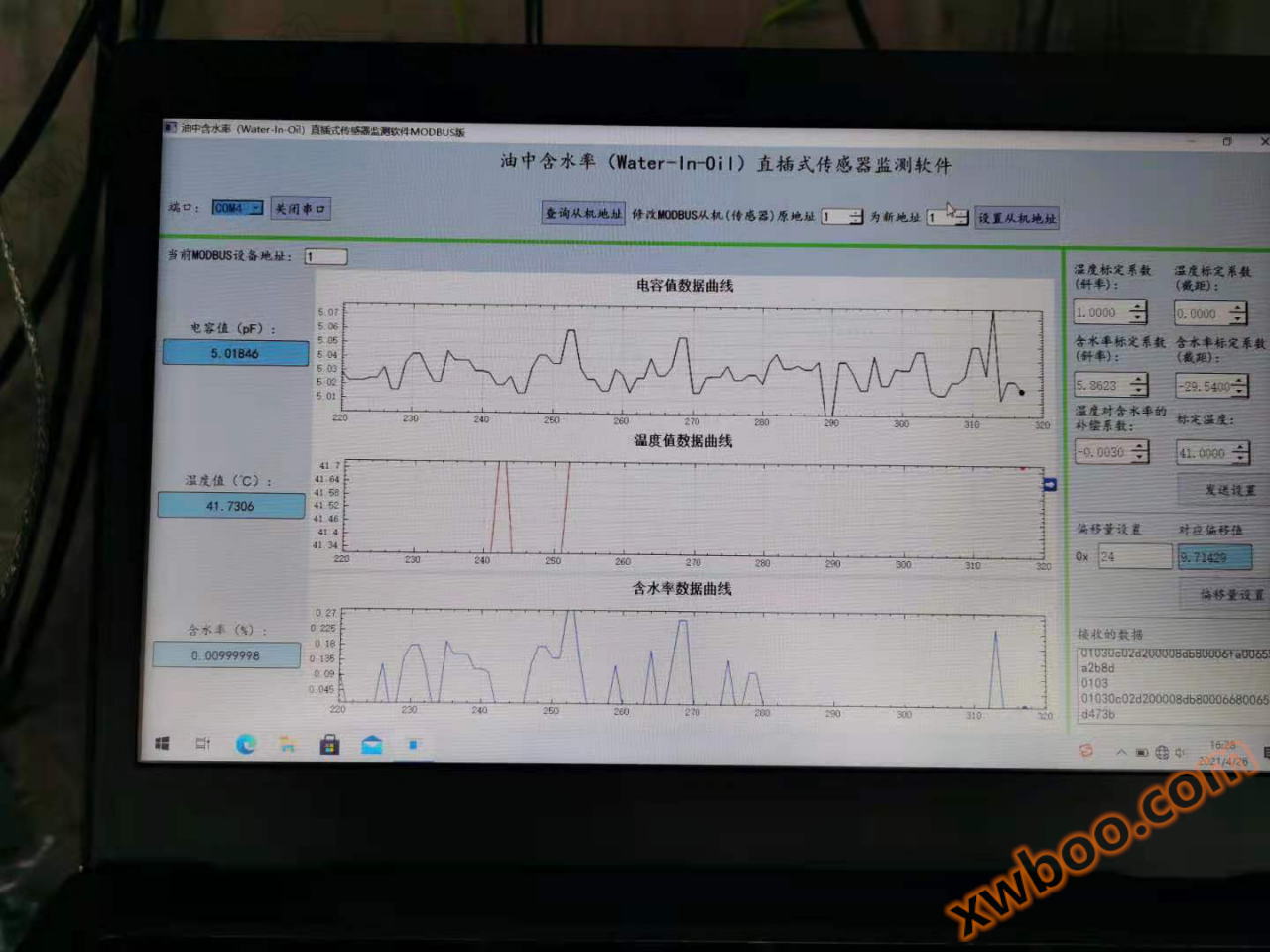

After calibration, the upper computer displays in real-time the moisture content and temperature of the lubricating oil in the return pipeline of the rolling mill

After calibration, the upper computer displays in real-time the moisture content and temperature of the lubricating oil in the return pipeline of the rolling mill Remote monitoring platform

Remote monitoring platform