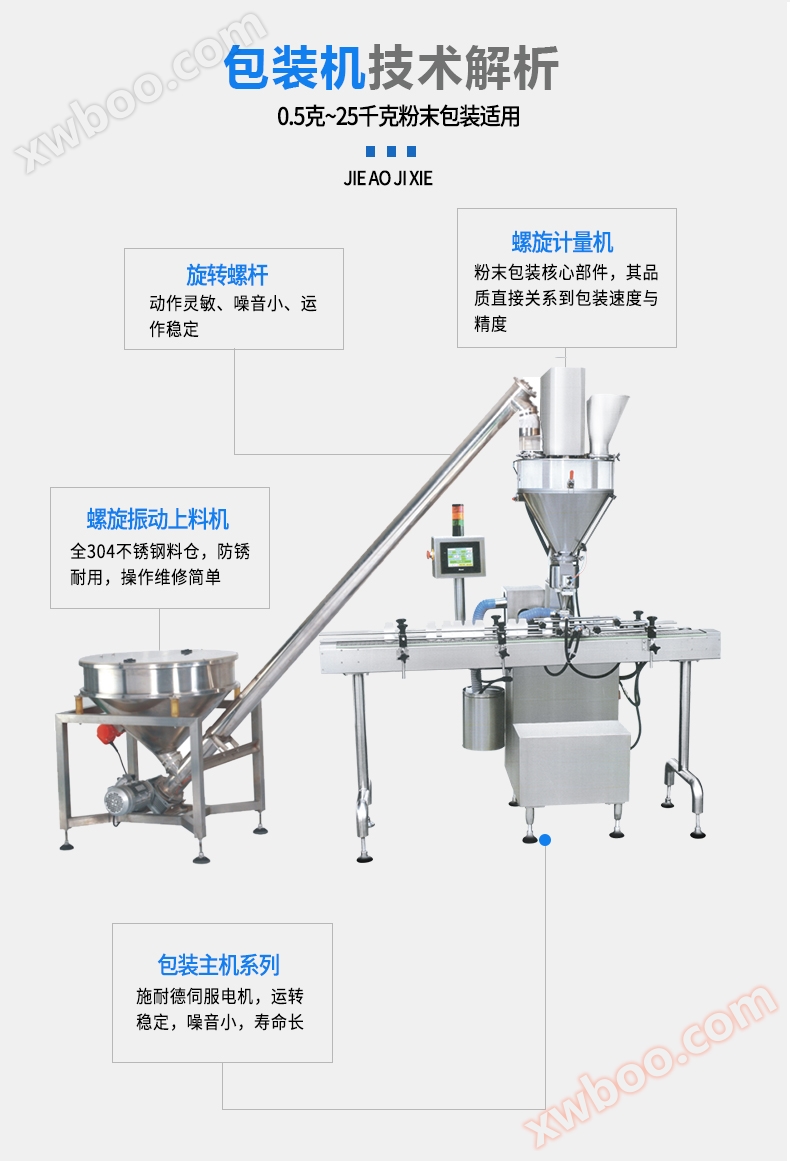

workflow:To tank→ Tank support → Vibration → Measurement and filling → Vibration → Vibration → Weighing feedback → Supplementary filling → Weight inspection and over tolerance removal → Tank discharge.

1Equipment features:

1Single row dual head filling, main filling and supplementary filling, ensuring high canning accuracy.

2Servo and pneumatic systems control the support and horizontal movement of tanks, with accurate positioning and fast speed.

3Servo motor and servo drive control screw, with stable performance and high precision.

4All stainless steel structure; Horizontal opening type material box (polished inside and outside), easy to clean.

5、PLCControl, touch screen human-machine interface display, easy to operate.

6A weighing system with high reaction speed ensures high canning speed and precision.

7The filling head is equipped with a handwheel to adjust the height, making it easy to achieve external bell shaped canning.

8Equipped with dust removal device, connected to negative pressure pipeline, no dust pollution to the environment.

9Horizontal linear structure, small footprint, easy to clean.

10The fixed screw installation structure does not produce metal pollution during canning.

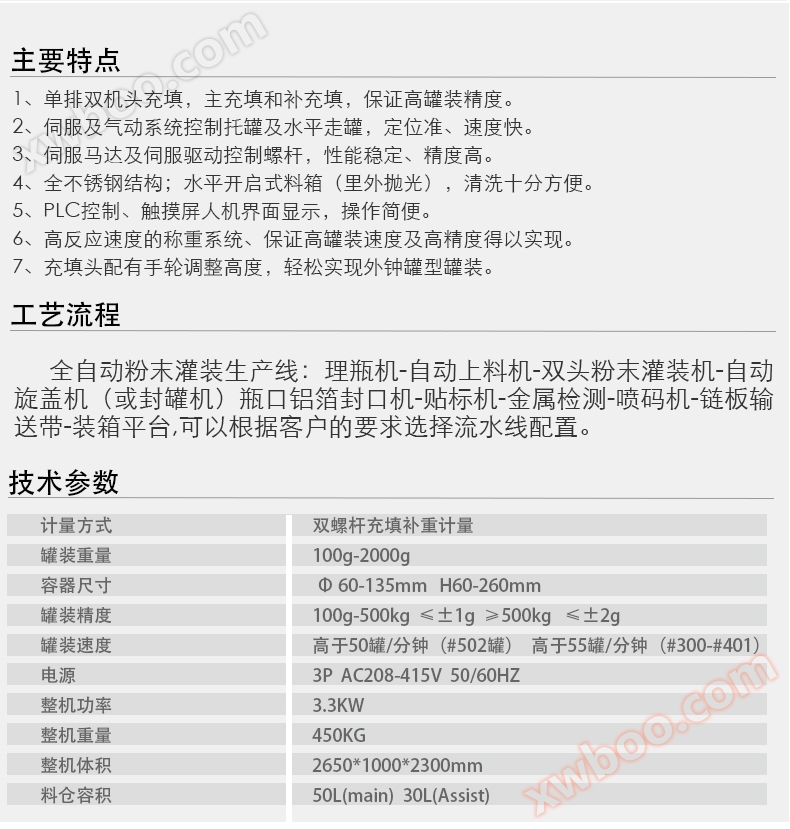

2Technical parameters

measuring method |

Measurement of twin-screw filling head |

Canned weight |

100g-2000g |

Container size |

Φ 60-135mm H60-260mm |

Canned precision |

100g-500kg ≤±1g ≥500kg ≤±2g |

Canning speed |

Above 50 cans/minute (# 502 cans) above 55 cans/minute (# 300- # 401) |

power supply |

3P AC208-415V 50/60HZ |

Whole machine power |

3.3KW |

Whole machine weight |

450KG |

Whole machine volume |

2650*1000*2300mm |

hopper capacity |

50L(main) 35L(Assist) |