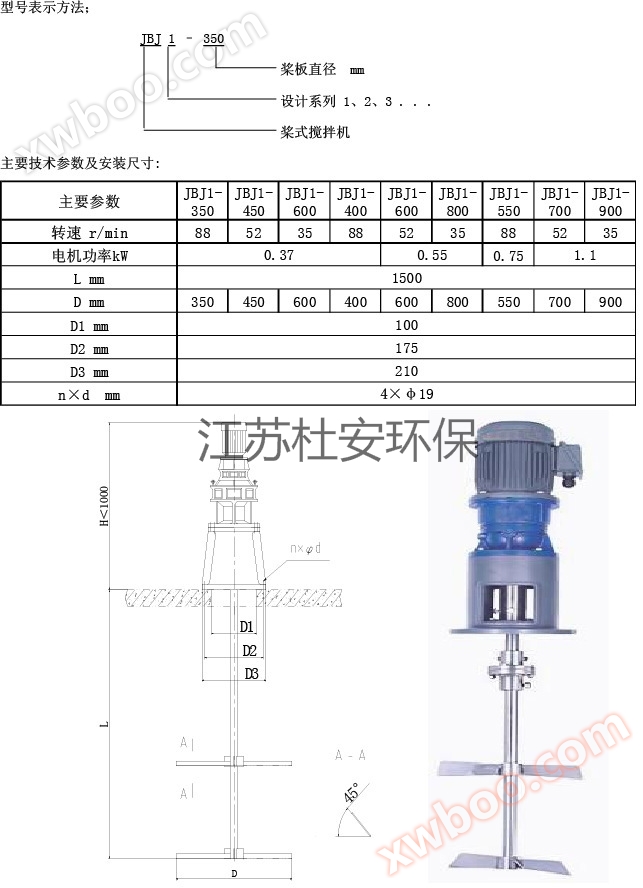

Intermediate pool paddle mixer, high viscosity paddle mixer, JBJ1-1200 paddle mixer

Jiangsu Du'an Environmental Protection

Construction and Materials of JBJ1-1200 Paddle Blender

1)Blender structure

The vertical mechanical mixer consists of a horizontally arranged motor, gear reducer, mixing shaft, and impeller. The electric motor and gear reducer are assembled together.

2)Electric motor and deceleration device

The electric motor and deceleration device are assembled as a complete set of equipment.

① Electric motor

The technical specifications of the electric motor are as follows:

-The material and performance of the electric motor comply with the Basic Technical Requirements for Rotating Electrical MachinesGB755-87Standard,ASTMandIECThe relevant technical standards issued.

-Electric motors are suitable380VAC 3PH 50HzThe insulation level of the motor stator winding and stator leads for power operation isFGrade, shell protection levelIP55Outdoor vertical installation.

② Deceleration device

The reduction device of the vertical mechanical mixer is gear reduction, and the selected material and performance meet the following technical specifications:

-The material of the gearbox body is cast steel, which is strong and sturdy. Cracks, sand holes, air holes, and other phenomena are not allowed during casting.

Fast mixer gear reduction, helical gear design, and fully sealed oil bath lubrication structure. The gearbox is driven by helical gears and does not allow the use of turbine worm structures; The transmission efficiency of the gearbox shall not be lower than95%.

-The deceleration device can transmit the required power for operation under various design conditions and withstand the load transmitted by the mixing shaft; All gears have protective measures to avoid impact loads.

-The bearings adopt standardized products and can work continuously under the most unfavorable design conditions, with a basic rated lifeL10no less than100,000Hour.

-The lubrication system provides absolutely reliable continuous oil supply to the gears and bearings, and no separate oil pump can be installed. The oil level in the gearbox can be checked through a bull's-eye mirror or oil level gauge.

3)Support for mixing shaft

The support of the mixing shaft has the following technical specifications:

① The support of the mixing shaft does not extend into the pool, can withstand the weight of the mixing shaft and impeller, and can withstand the required torque, bending moment, and axial load for operation; The support form ensures that during the operation of the mixing mixer, most of the shaft deflection force is not transmitted to the reducer gears and bearings.

② The supporting bearing of the mixing shaft is lubricated with grease and equipped with an oil cup for replenishing grease. The basic rated life of the supporting bearing isL10no less than100,000Hour.

4)Mixing shaft and impeller

① Mixing shaft

-The mixing shaft adopts316LStainless steel, without using fiberglass or composite materials; Straighten the shaft during machining.

-The mixing shaft has sufficient torsional and bending stiffness: the calculated tensile force of the shaft is at least lower than its material tensile yield force3The calculated shear force value is at least lower than the material's shear yield force value3.5Twice.

-The mixing shaft is equipped with underwater auxiliary bearings.

② Impeller

The impeller consists of a cast hub and blades, made of316LStainless steel, the connection between the wheel hub and blades is designed for easy disassembly and anti-corrosion effect, and has the following characteristics:

-The impeller is an efficient axial flow impeller.

-The blades are bolted to the central hub, which is connected to the shaft.

-The number of leaves is not more than3The blade has sufficient strength and rigidity, and does not deform during rotation.

Testing standard for folding paddle mixer

The inspection, acceptance, warranty, and rejection of equipment shall comply with the relevant provisions of general technical regulations and meet the following conditions:

The perpendicularity of the blade to the axis is equal to the length of the slurry plate0.4%And not exceeding5mm.

The straightness of the axis per meter is less than0.25mm.

After the installation of the mixing equipment, a load test run of the mixing working medium is carried out, and the test run is filled in the mixing tank2/3The above volume of medium. During the trial operation, the equipment ran smoothly without any abnormal vibration or noise. The load trial operation time shall not be less than24h.

Scope of supply: Motor reducer, machine base, spindle, blade and installation accessories. The on-site control box for Jiangsu Du'an Environmental Protection's folding paddle mixer is provided by Jiangsu Du'an Environmental ProtectionProvided as a matching item, the control box adopts a perspective double-layer door and stainless steelMade of 304 material, the bracket is also made of stainless steel 304 material, which can be firmly fixed; The thickness of the board shall not be less than 1.5mm, the outdoor protection level shall be IP55, and the indoor protection level shall not be lower than IP4X. Protective switches, control switches, and logic components shall be installed inside the box. The panel shall be equipped with a multifunctional meter, conversion switch, on/off button, emergency stop button, and operation indicator light. When the equipment fails, the operation of the equipment shall be stopped. Jiangsu Du'an Environmental Protection provides complete electrical control schematics, wiring diagrams, general layout of electrical component locations, specific wiring diagram numbers, and a list of electrical component configurations for each control box, based on the performance requirements of the equipment provided and the aforementioned control requirements.

Must havePrimary components and operational functions such as circuit breakers, AC contactors, thermal relays (if required), and frequency converters (if required), with the main electrical components (circuit breakers, contactors, thermal relays) using Schneider, ABB, or Siemens products.