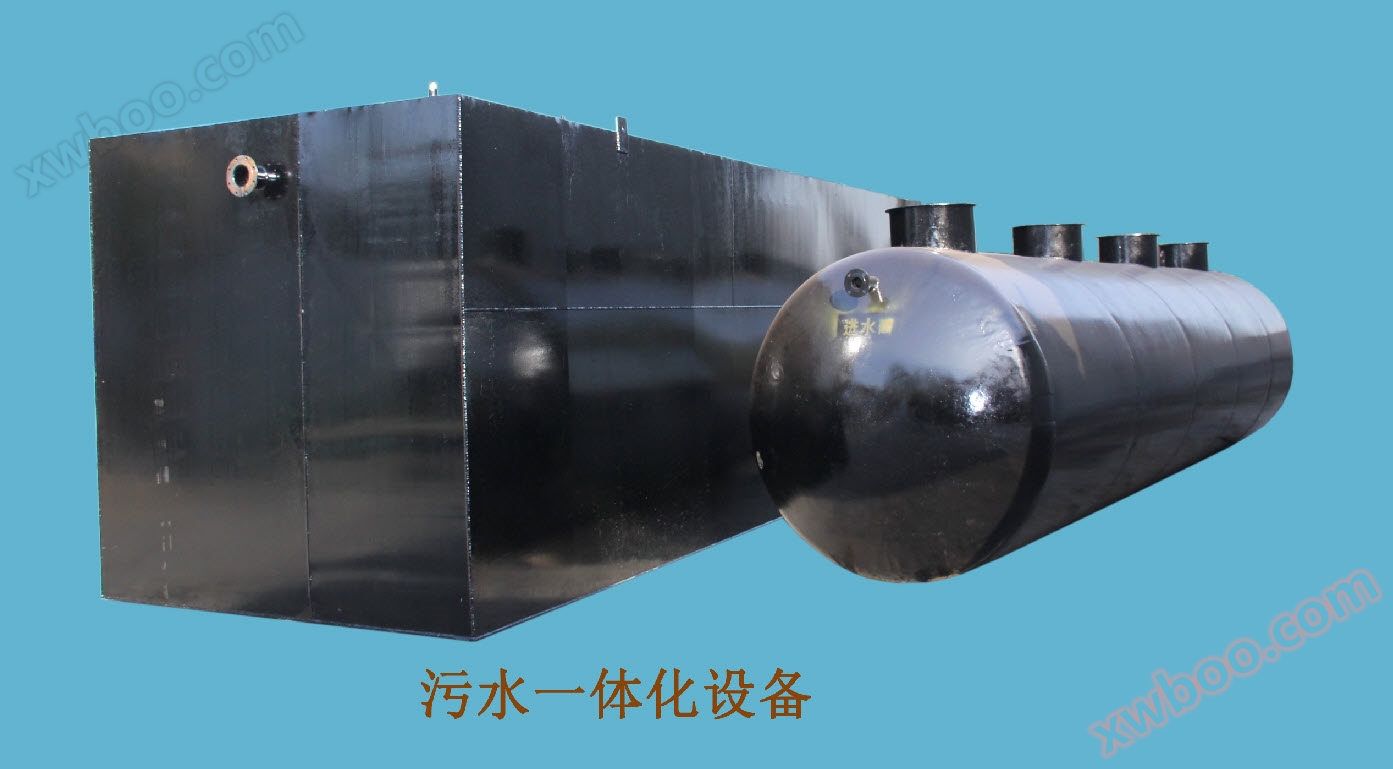

Integrated sewage treatment equipment

one.Product Application

The QTWT integrated sewage treatment equipment adopts the world's advanced biological treatment process, integrating the removal of BOD, COD, and NH-N, and is currently a convenient sewage treatment equipment. It is widely used in the treatment of domestic sewage in hotels, restaurants, shopping malls, highway service areas, office buildings, residential communities, villages, towns, factories, mines, military forces, tourist attractions, scenic spots, etc., replacing septic tanks with low removal rates and treated effluent that cannot meet national comprehensive discharge standards. Through practical application, it has been shown that the QTWT integrated domestic sewage treatment device is an equipment with ideal treatment effect and convenient management.

two.Product Features

(1) It can be buried underground and the surface can be used as green or square land, so the equipment does not occupy the surface area, does not require building, and does not require heating and insulation.

(2) Composed of two sets of equipment made of steel structure, using domestically pioneered anti-corrosion coating for corrosion prevention. It is resistant to acid, alkali, salt, gasoline, kerosene, aging, abrasion, and rust. After applying the coating, the anti-corrosion life of the equipment can generally reach more than 15 years.

(3) The AO biological treatment process adopts a push flow biological contact oxidation tank, which has a better treatment effect than fully mixed or two-stage series fully mixed biological contact oxidation tanks. And it has a smaller volume than activated sludge tanks, stronger applicability to water quality, good impact resistance, stable effluent water quality, and will not cause sludge expansion. At the same time, a new type of elastic three-dimensional material is used in the biological contact oxidation tank, which has a larger actual specific surface area, microbial biofilm formation, and convenient membrane removal. Under the same organic load conditions, it has a higher removal rate of organic matter than other fillers. Can increase the solubility of nutrients in water in the air.

(4) Due to the use of a biological contact oxidation tank in the AO biological treatment process, the volume load of the packing is relatively low, and the microorganisms are in the self oxidation stage, resulting in less sludge production. In addition, the moisture content of the sludge produced by the biological contact oxidation tank is much lower than that of the sludge produced by the activated sludge tank. Therefore, the amount of sludge generated by the QTWT integrated domestic sewage treatment device is relatively small, and generally only needs to be discharged once every 90 days.

(5) In addition to using conventional measures such as vibration isolation pads and silencers, new sound-absorbing materials have also been installed on the inner wall of the blower room, reducing the noise level during equipment operation to below 50 decibels and minimizing its impact on the surrounding environment.

(6) Equipped with soil deodorization measures, it utilizes the upper space of the reinforced concrete structure pool to set up improved soil and air distribution pipes. When odorous components dissolve in the water contained in the soil through the soil layer, they are then transferred into the soil due to surface adsorption and chemical reactions, and decomposed by microorganisms to achieve deodorization.

(7) The fully automatic electrical control system and equipment damage alarm system have good reliability, so there is generally no need for dedicated personnel to manage them, only monthly or quarterly maintenance and upkeep are required.

3、 Process flowchart

1.The main process is“A/O/OBiological contact oxidation process

2.Process flow description of integrated domestic sewage equipment

Wastewater is intercepted by a grid to remove solid suspended solids such as waste residue, paper scraps, and fibers from the water. It enters a regulating tank, where it is homogenized and evenly distributed before being pumped to an A-level biological tank. In the A-level biological tank section, heterotrophic bacteria hydrolyze soluble organic matter into organic acids, breaking down large organic matter into small organic matter. Insoluble organic matter is converted into soluble organic matter, and pollutants such as proteins and fats are ammoniated. There are aerobic microorganisms and digestive bacteria in the O-level biological pool section, where aerobic microorganisms decompose organic matter into CO2 and H2O; Under sufficient oxygen supply conditions, the nitrification process of nitrifying bacteria oxidizes NH3-N to NO3-, which is then returned to the A-level biological tank through reflux control. Under anaerobic conditions, the denitrification process of anaerobic bacteria reduces NO3- to molecular nitrogen. The effluent from the contact oxidation tank flows automatically into the sedimentation tank for sedimentation, and the effluent from the sedimentation tank enters the disinfection tank for chlorine dioxide disinfection. The disinfected effluent meets the discharge standards.

Part of the sludge in the sludge tank is returned to the A-level biological tank, and the remaining sludge is regularly transported for disposal.

1、AGrade biological pool(Hypoxia pool)

Further mixing the sewage and fully utilizing the efficient bio elastic packing material in the pool as a bacterial carrier, the difficult to dissolve organic matter in the sewage is converted into soluble organic matter by facultative microorganisms, and the large molecular organic matter is hydrolyzed into small molecular organic matter, which is conducive to further oxidation and decomposition in the O-grade biological treatment tank. At the same time, the refluxed nitrate nitrogen can undergo partial nitrification and denitrification under the action of nitrifying bacteria to remove ammonia nitrogen.

2、OGrade biological pool(biological contact oxidation tank)

This pool is the core part of this sewage treatment, divided into two sections. In the first section, under high organic load, a large number of microbial communities of different species attached to the packing participate in biochemical degradation and adsorption, removing various organic substances from the sewage and significantly reducing the organic content in the sewage; In the latter stage, under the condition of reduced organic load, the action of nitrifying bacteria degrades ammonia nitrogen in the sewage under sufficient oxygen conditions, while also reducing the COD value in the sewage to a lower level, thus purifying the sewage. The two-stage design can degrade water quality into gradients, achieving good treatment effects. At the same time, the design adopts corresponding diversion and turbulence measures to make the design more reasonable.

The aeration method adopts microporous aeration, which can effectively avoid pipeline blockage caused by sludge generated during wastewater treatment, prolong the service life, and improve oxygen utilization efficiency.

3Sedimentation tank

Precipitation is the process by which suspended solids in wastewater separate from water under the influence of gravity. This process is simple and easy to implement, with good separation effect, and is often an indispensable process in various sewage treatment systems.

The function of the sedimentation tank here is to perform solid-liquid separation and remove the biofilm and suspended sludge peeled off from the biochemical tank, so as to truly purify the sewage and stabilize the effluent effect.

4Disinfection pool

The effluent from the secondary sedimentation tank flows into the disinfection tank for disinfection, ensuring that the effluent quality meets the hygiene requirements and is discharged as qualified.

Design a disinfection device, guide plate, and disinfection design in the disinfection pool using a chlorine contact method. This dosing method has the characteristics of convenient dosing, simplicity, and safety. After disinfection, the water is discharged into the municipal sewage pipeline or nearby water areas.

5Sludge tank

The sludge from the secondary sedimentation tank is regularly discharged into the sludge tank through a sludge pump, and a sludge return device is installed. Some of the sludge is returned to the A-level biological treatment tank for nitrification and denitrification, which not only reduces the generation of sludge but also facilitates the removal of ammonia nitrogen from the sewage. The remaining sludge is subjected to sludge concentration, aerobic digestion, and the supernatant of the sludge is discharged back into the regulating tank for further treatment. The remaining sludge is regularly pumped out (two to three times a year).

6Clear water tank

The effluent from the disinfection tank enters the clean water tank and can be discharged directly to meet the standard or reused as reclaimed water.

4、 Technical features

1Stay time

The retention time of sewage in the equipment pool reaches 16 hours, and it is treated with secondary biochemical treatment. The retention time is sufficient, and the effluent meets the standard and is stable;

2. Equipped with nitrification liquid reflux pump and sludge reflux pump, ensuring the effluent ammonia nitrogen index while reducing sludge volume;

3. The fan and water pump are all one backup and one use, eliminating single continuous use;

4. The electronic control adopts PLC microcomputer touch screen fully automatic control, eliminating the old-fashioned manual button control;

5. The inlet is equipped with a disc water distributor to ensure uniform inlet and prevent short flow;

6. The inlet pipe is equipped with a flow control system, which can control the inlet flow rate and ensure stable inlet flow;

7. The aeration head is inverted, and the corners are inclined to prevent dead corners in aeration; Intelligent control of air volume to prevent disturbance of biofilm sludge; The aeration tube is installed in a circular shape to prevent uneven aeration;

8. Can be buried underground or placed on the ground, modular design, compact structure, saving floor space;

Installation and debugging section

1、 Source of sewage

Kitchen wastewater, personal sewage, and laundry wastewater. Other domestic sewage components.

Wastewater is generated on site throughout the day Left and right. The buried integrated sewage treatment equipment should select a matching sewage quality source before commissioning.

2、 Pre debugging work

1. Venue selection

2. Foundation fabrication

1) The installation of buried integrated sewage treatment equipment should be based on the foundation drawing Before installation, the buried integrated sewage treatment equipment should be appropriately protected with slope protection to prevent collapse if the soil quality is unknown. (Please refer to the drawing for details), it should be done in advance0.4mPre embedded thick reinforced concrete structure12piece10mmThick steel embedded parts.(Refer to the drawing for details)

2) Natural maintenance needs for the concrete foundation of the foundation pit of the buried integrated sewage treatment equipment14-21day

3) The buried integrated sewage treatment equipment is hoisted and transported to the designated location.

3、 Installation instructions for buried integrated sewage treatment equipment

1. The installation of the equipment must be carried out in accordance with the relevant installation specifications for buried integrated sewage treatment equipment. The civil engineering of the equipment must be undertaken by a formal construction team. This equipment can be installed in two forms: one above the floor and the other below the floor. This project is installed below the floor, while other equipment is installed on the floor.

2. Before installation, the civil engineering shall be inspected and accepted. The size and specifications of the concrete bottom plate of the equipment shall be the same as those in the plan and installation drawings, and the average bearing capacity of the foundation shall be 20T/m2The above foundation must be level. If the equipment is installed under the floor, the relative elevation of the foundation floor must be the same as the height of the equipment. The excavation width around must be at least 500mm away from the foundation edge for pipeline installation.

3. According to the installation diagram, place the equipment in place and use a crane to lift it into the position of the equipment box. The direction must not be wrong and the distance between each other must be accurate (800mm). Place the equipment in place and connect the pipelines. Special adhesive is used to connect engineering plastic pipes, and it is required that each connection interface is free of oil stains. After sanding with sandpaper, a layer of adhesive is applied with a brush. After the adhesive layer is slightly dry, the connection pipe should not leak. Weld the equipment base firmly to the embedded steel plate on the foundation, remove welding slag, and apply three coats of epoxy resin.

4. Install dosing devices, disinfection devices, and all connected pipelines according to the process requirements and actual situation.

5. Connect the control lines of the electrical control cabinet, the connections between the equipment, and the electrical control cabinet to the power supply. When wiring, pay attention to the direction of rotation of the fan and motor, which must be the same as the direction pointed by the fan.

Attached are equipment layout plan, pipeline layout plan, and foundation plan.

4Lifting and positioning of buried integrated sewage treatment equipment

Install accident bypass pipe and inlet valve well

After the underground integrated sewage treatment equipment arrives at the commissioning site, use a suitable tonnage crane to lift the sewage treatment equipment to the designated commissioning position. The equipment should not be placed in the wrong direction and the distance between each other must be accurate to facilitate subsequent work

2. Installation of external pipelines, circuits, and cable trays for sewage treatment equipment

3. After the equipment is in place, external pipeline installation, circuit connection, and bridge installation will begin.

4. The external pipeline connection interfaces should be free of oil stains. Use sandpaper to polish the connection interfaces and apply a layer of glue. Wait for the glue layer to dry slightly before connecting the pipelines. It is required that there should be no leakage at the connection pipeline.

5. The electrical control cabinet is placed on the side of the main equipment, and the external circuit connects the control line of the electrical control cabinet, the sewage equipment connection, and the electrical control cabinet to the power supply. When connecting the power line to the sewage equipment, pay attention to the direction of the fan and motor between the sewage equipment.

6. When wiring equipment, it is necessary to fix the cable trays that should be installed between the devices and prepare for the routing of power lines.

7. Internal circuit and pipeline connections

8. The internal circuits and pipeline connections must be strictly connected according to the internal electrical and pipeline wiring diagram provided by the manufacturer (see equipment internal electrical and pipeline layout diagram for details).

5、 Inspection before equipment linkage debugging

1. The rotation and operation of fans and motors in the idle testing equipment room, as well as the reliability of the operation of components in the electrical control cabinet.

2. Check the lubricating oil filling status of the fan in the equipment room.

3. Check the firmness of the internal and external pipeline connections.

4. Check the connection status of internal and external circuits.

5. Inject sewage into the buried integrated sewage treatment equipment and check for any leakage at the connections of each pipeline

6. Start the fan and check the operation of all equipment in the domestic sewage system for any abnormal vibration, noise, etc.

6、 Operation process of buried integrated sewage treatment equipment

(1) Normal operation process of sewage treatment plant

Automatic operation:

Turn on the power supply of the distribution cabinet, and at the same time, turn on the chlorine dioxide generator and flocculant dosing pump. Set the control mode to automatic mode, and the equipment will automatically operate according to the water level of the regulating tank.

Manual operation:

Start the aeration tank fan → Start the regulating tank lifting pump → Start the flocculant dosing pump → → Start the chlorine dioxide disinfection device

(2) Specific operational steps during actual debugging

1. Fill the contact biochemical tank with sewage.

2. Start the fan to aerate and oxygenate the sewage in the pool.

3. Recharge the water and continue aeration.

4. Repeatedly running like this, the daily water intake time is relatively prolonged.

5. At the same time, the contact with the filling material in the biological pool can also be observed.

6. The domestication of microorganisms requires a long time, which can accelerate the formation of biofilms.

7. Precautions

(1) Floating debris on the surface of the aeration tank should be regularly removed.

Regularly observe the operation of the equipment and treat the effluent, and promptly address any abnormal situations.

8. System monitoring

(1) Observe the color changes of sewage.

7、 Description of dosing device

1. The configuration of the drug solution involves pouring the drug into the dosing tank, starting to inject clean water into the water supply valve, and closing the water valve when a certain amount is reached. The concentration of the drug is generally controlled between 10% -20%.

2. Adjust the flow rate to the set delivery rate to deliver 1% -50% to the dosing point

%The rated dosage of the concentration.

8、 The sewage treatment plant is operating normally

1. Wait for the sewage to fill the contact tank.

2. Start the fan, open the intake valve for aeration, and adjust the air volume (with an air to water ratio of 12:1). Once adjusted, it generally remains unchanged.

3. The sewage from the contact oxidation tank flows automatically into the sedimentation tank, and the sludge from the sedimentation tank flows automatically to the regulating tank. The reflux rate varies depending on the content of activated sludge in the aeration tank and is determined according to the amount of settled sludge. Excess sludge is lifted to the sludge tank.

4. Adjust the chlorine dioxide disinfection device and dosing device according to the water volume, and adjust the dosing amount of the disinfection dosing device according to the actual usage situation by adjusting the metering pump for dosing.

(1) The domestic sewage treatment system adopts a fully automatic operation mode, and the fully automatic control process is as follows:

1. The aeration fan is linked to the domestic sewage lifting pump (with a linkage signal provided by the control box). When the sewage is cut off, the lifting pump stops and the fan can automatically operate intermittently to ensure the activity of the biofilm. The intermittent operation time is 90 minutes for operation and 95 minutes for shutdown;

2. Lift the sludge pump, and the sludge reflux is controlled by time setting.;

3. The control timing can be adjusted arbitrarily, and it is equipped with automatic protection functions for faults such as overcurrent, phase loss, overvoltage, undervoltage, etc;

9、 Maintenance, upkeep, and precautions for buried integrated sewage treatment equipment

When the equipment is buried underground, attention should be paid to ensuring that there is no water accumulation around the equipment during rain. The discharge outlet of the equipment must be below -0.60m relative to the ground level, and no vehicles are allowed to pass above the equipment. Generally, the equipment should not be emptied of internal sewage to prevent groundwater from floating the equipment.

2. Equipment management must establish a regular maintenance system, with the main vulnerable parts being the fan and water pump. The fan direction cannot be reversed, and if sewage enters, it must be cleaned and the oil replaced before use. Before starting the fan, attention must be paid to whether the air valve is open.

3. If maintenance or replacement of other components is required during the operation of the equipment, it is necessary to ensure that three or more personnel are present on site. After sufficient ventilation, maintenance personnel must fasten their safety belts and wear gas masks before entering to prevent oxygen deficiency and poisoning accidents in the pool. Measure plan:

It is necessary to drain the sewage from the pool

⑵ Dilute the accumulated water at the bottom of the sewage tank with clean water

If open flames are to be used in a closed water tank, ventilation treatment must be done first before personnel enter

⑷ It is necessary to ensure that there are at least three personnel on site

⑸ Take emergency measures

Check the power circuit and turn off the power.

4. The dosing device should regularly check the operation of the pump.

5. Pay attention to moisture prevention for pumps and motors; The operation, use, and maintenance of the metering pump are detailed in the metering pump manual.

6. Check that there is no leakage in the pipeline.

7. All lubrication parts must be regularly lubricated.

8. For specific maintenance and upkeep of the fan, please refer to the fan manual.

10、 Possible abnormal situations and troubleshooting solutions during the debugging process of sewage treatment system

|

Serial Number |

Possible abnormal situations |

Possible causes of abnormal phenomena |

Solution |

|

1 |

The water pump cannot pump water or has very little water output |

1、 Incorrect wiring of water pump motor 2The water pump is entangled by foreign objects 3The water pump motor is damaged |

1、 Replace the three-phase wiring of the motor 2、 Remove foreign objects from the pump chamber of the water pump 3、 Replace the water pump |

|

2 |

The effluent color does not meet the standard |

1、 The original water color exceeds the standard 2、 Insufficient dosage of medication 3、 The effect of the medication is not ideal |

1、 Control the chromaticity of raw water within the design range 2、 Appropriately increase the dosage of the medication 3、 Choose a more effective medication |

|

3 |

effluentCODNot up to standard |

1、 Insufficient microbial nutrition 2、 Insufficient aeration rate 3、PHAbnormal values and water temperature |

1、 Add proportionally to the poolN、PWaiting for nutrients. 2、 Increase the aeration rate. 3AdjustmentPHAnd the water temperature. |

|

4 |

There are clusters of bubbles rising in the pool |

Aeration pipeline blockage |

It should be cleaned or replaced immediately. |

|

5 |

Uneven agitation of the liquid surface |

There are blind spots in aeration |

Check if there is any mud accumulation at the four corners of the pool bottom, and promptly clear the sediment. |

|

6 |

A lot of white foam appears |

1The water contains a large amount of foaming substances such as detergents. 2The quality of the incoming water has changed. |

1、 Defoamers should be added to the regulating tank to remove the influence of surfactants. Or spray foam in the pool with water gun regularly. 2、 Measure the quality of the incoming water and adjust the concentration of the incoming water. |

|

7 |

Foam is tawny and gray |

The sludge is too old or the sludge is crushed and adsorbed on the bubbles. |

Increase the amount of sludge discharge. |

|

8 |

Bubbles are sticky and not easily broken |

High load, incomplete decomposition of organic matter. |

Reduce the concentration of incoming water. |

11、 Main construction machinery

Necessary tools and equipment for on-site debugging of generators, water trucks, cranes, transport vehicles, excavators, sewage trucks, etc

12、 Security precautions

1. All personnel participating in the clean water debugging must wear safety helmets.

2. Check if the power lines connecting the devices are connected correctly.

3. Determine the load of the underground integrated sewage treatment equipment linkage equipment to ensure normal commissioning.

4. Protective measures such as insulated gloves for commissioning and operating personnel of buried integrated sewage treatment equipment.

5. During the commissioning period of the buried integrated sewage treatment equipment, there should be a dedicated person to guard it.

6. It is not allowed to pile soil, materials, or park machinery within 1 meter of the upper edge of the foundation pit.

7. Construction personnel outside the foundation pit are not allowed to throw debris into the pit. When passing tools under the foundation pit, they must be firmly secured before releasing them.

8. Personnel underground should rest away from the edge of the foundation pit and the slope to prevent carelessness.

9. All construction machinery must obey the command of the commanding personnel, and personnel should try to stay away from the construction machinery as much as possible. If necessary, notify the operators first and wait for a response before approaching