Overview:

The IH chemical pump is a single-stage single suction cantilever centrifugal pump. Its markings, rated performance points, and dimensions are equivalent to the international standard ISO2858, which is determined to replace the F-type corrosion-resistant centrifugal pump as an energy-saving and updated product. Can meet the transportation of corrosive liquids with viscosity similar to water in chemical processes.

The temperature of the medium transported by the pump is generally between -20 ℃ and 105 ℃. If necessary, appropriate cooling measures can be taken to increase the temperature of the medium transported.

The maximum working pressure of the pump is designed to be 16 bar.

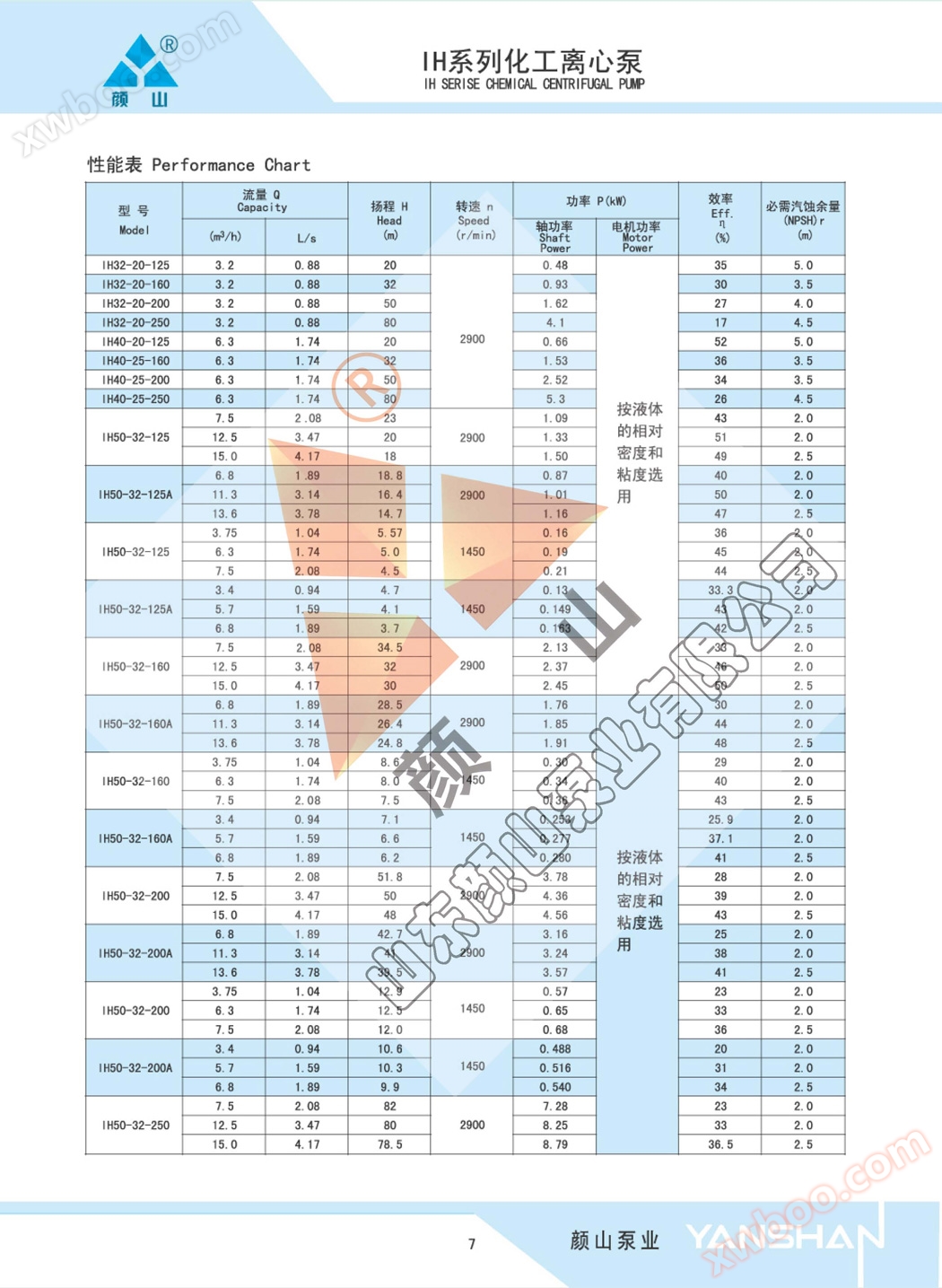

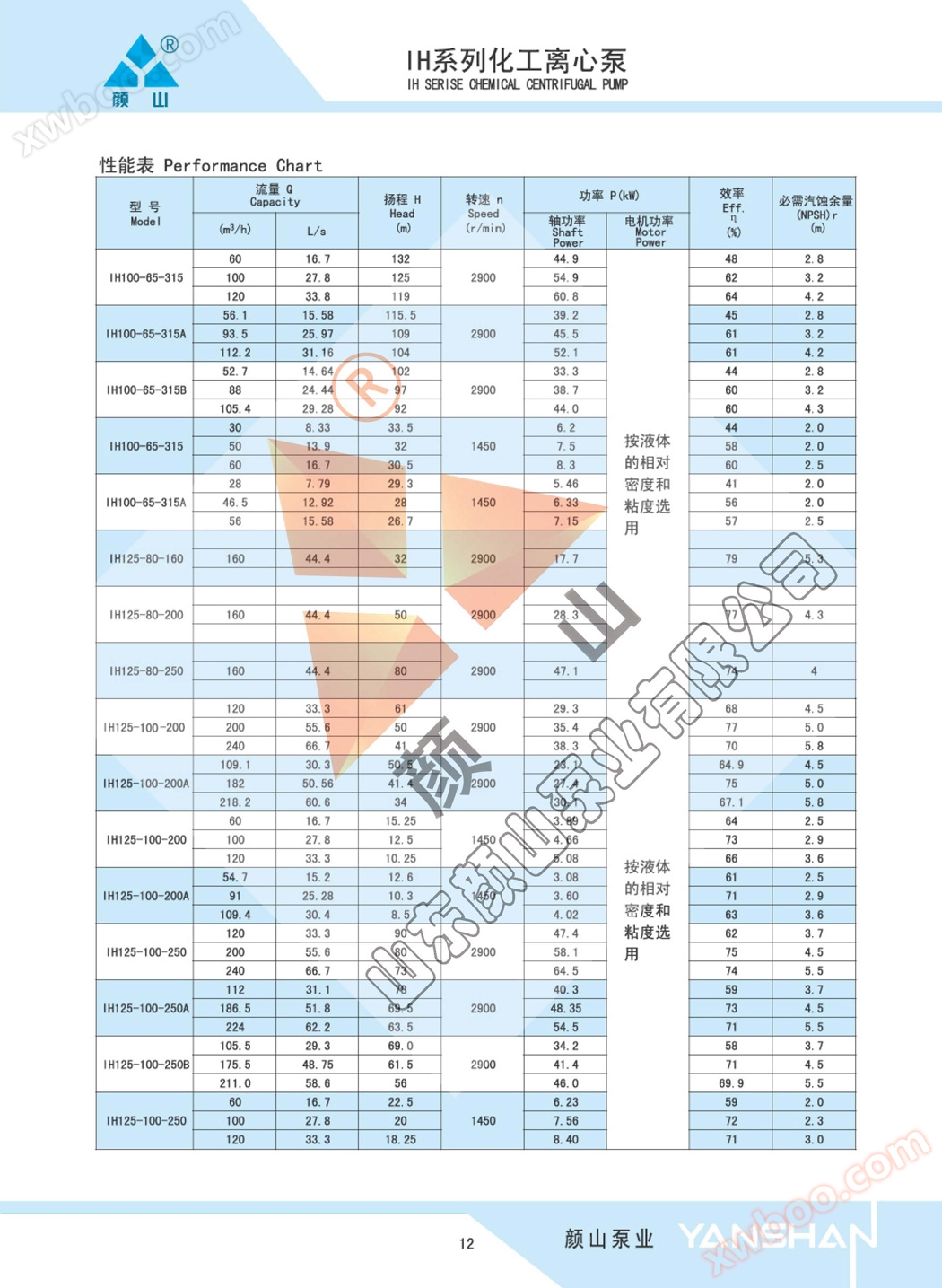

The performance range (design point) of this series of pumps: when the flow rate is 1.6-400m3, the head is 5-125m

According to the corrosion of the pump caused by the conveyed medium, users can choose the appropriate material for the liquid contact part. The main parts that come into contact with the medium of the pump are made of materials such as 1CrNi9, 1Cr18Ni9Ti, 0Cr18Ni12Mo2Ti, 1Cr18Mn13Mo2CuN, 303, 305, 306, 307, 402, etc. Users are allowed to choose other materials suitable for the production of this series of pumps.

Purpose:

IH type chemical pumps are suitable for a wide range of industries, such as chemical, metallurgical, power, papermaking, food, pharmaceutical, synthetic fiber, etc., for transporting corrosive or non polluting media.

Model meaning:

IH50-32-160A SI IH - International Standard Chemical Pump Series Products 50- Pump Inlet Diameter (mm) 32- Pump Discharge Diameter (mm) 160- nominal diameter of impeller (mm) A - same model impeller with reduced performance parameters after one cutting: SI - pump sealing type, SI is single end internal mechanical seal: 303- Material code for pump contact parts: 1Cr18Ni9