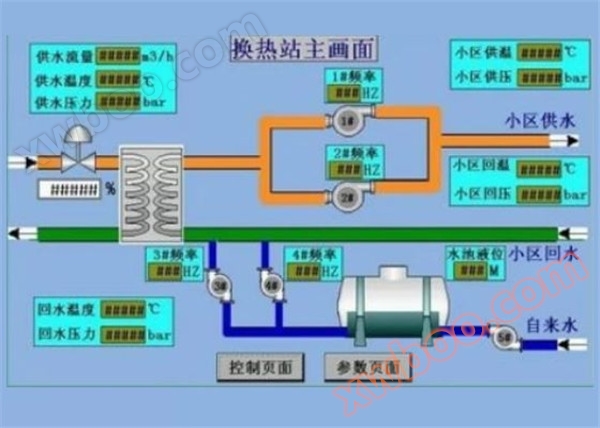

Control strategy and functions

1. Data collection

Mainly responsible for simulating the on-site process of the pipeline network (such as temperature, pressure, flow rate, electricity, heat, etc.), state variables (such as pump status, water level status, etc.), and comparing the upper and lower limits of corresponding physical quantities, PID operations, logical operations, etc.

The main task is to measure and display the following parameters, and the measurement results will be transmitted to the monitoring center.

① Pressure:

Primary network water supply pressure, primary network return pressure, secondary network water supply pressure and secondary network return pressure of each heating unit.

② Temperature:

Outdoor temperature, primary network water supply temperature, primary network return water temperature of each unit, secondary network water supply temperature, secondary network return water temperature, and other data.

③ Flow rate and heat:

Instantaneous water flow rate and heat, cumulative flow rate and heat, instantaneous water replenishment flow rate and cumulative water replenishment flow rate.

④ Valve position feedback:

Valve position feedback of electric control valve.

⑤ Frequency feedback:

Circulating pump frequency converter, water replenishment pump frequency feedback, current feedback.

⑥ Running status:

Remote, local, manual/automatic operation status of circulating pumps and make-up pumps.

⑦ Fault status:

Circulating pump frequency conversion fault, water replenishment pump frequency conversion fault.

2. Temperature control

The secondary water temperature control can be controlled according to the temperature control target value issued by the dispatch center, or it can be adjusted locally based on the outdoor temperature value transmitted by the dispatch center and the supply and return water temperature characteristic curve set by the on-site controller.

The temperature control target values or temperature characteristic curves of each station can be weighted and offset according to the actual heating environment of the thermal station.

The electric regulating valve can be controlled automatically or manually.

3. Pressure control

① Differential pressure setting: selectable manual/automatic setting

Automatically/manually adjust the speed of the variable frequency circulating pump based on the set or feedback secondary network supply and return water pressure difference, to stabilize the pressure difference within the required range.

It should be possible to observe the set value of the secondary network supply and return water pressure difference, the actual pressure difference, and the feedback value of the circulating pump frequency.

Can modify the set value of the secondary network supply and return water pressure difference locally and in the monitoring center.

② Return water pressure control

Control the return water pressure by adjusting the frequency of the water replenishment pump or adjusting the electric control valve once and twice. The system should be able to select and switch between one or both modes of operation through water replenishment. The ability to modify the return water pressure setting value, return water pressure low deviation setting value, and modify PID parameter values locally and in the monitoring center.

When using a water replenishment pump control, manual/automatic can be selected.

In automatic mode, PID calculation is performed based on the set value of return water pressure and the actual return water pressure to control the frequency of the water replenishment pump. In manual mode, the frequency of the water replenishment pump can be directly modified.

To prevent the system from being too short of water replenishment, which is not conducive to the operation of the water replenishment pump, the frequency converter of the water replenishment pump should be set to sleep mode.

③ Discharge pressure control

High limit setting for supply (return) water pressure. When the secondary supply (return) water pressure is higher than the upper limit set value during automatic operation of the drain valve, the drain valve opens. When it is lower than the lower limit set value, the drain valve closes. Measures should be taken to prevent the drain valve from repeatedly opening and closing.

In manual mode, the drain valve can be directly opened and closed

4. System protection

When the temperature of the secondary network supply water exceeds the high limit, the temperature of the primary network return water exceeds the high limit, or when all circulating water pumps stop or power is cut off, the primary side electric control valve automatically closes.

When the pressure value of the secondary network water supply is higher than the high limit value, or when the pressure value of the secondary network return water is lower than the low limit value, in order to protect the equipment, the operation of the entire heat exchange unit is stopped until the fault is resolved, and then put back into operation.

Set low and high opening settings for the regulating valve to ensure that it operates within a certain set range during automatic operation, without closing to 0% or opening ...