GTS30 Fully Automatic Vacuum Shaped Can Sealing Machine

Fully automatic vacuum shaped can sealing equipment. The fully automatic vacuum sealing of various specifications (square cans, oval cans, etc.) of shaped tinplate or aluminum cans is suitable for automated large-scale production of canned meat, canned fish, canned aquatic products, canned fruits and vegetables, etc. This machine has the characteristics of stable operation, high vacuum degree, and sealing quality that meets standards. The key components are processed using ultra high precision equipment, especially for the phenomenon of unqualified corner sealing in most irregular cans, which is precisely optimized and adjusted to ensure the continuous stability of the whole machine operation and sealing quality.

Fully automatic vacuum shaped can sealing equipment. The fully automatic vacuum sealing of various specifications (square cans, oval cans, etc.) of shaped tinplate or aluminum cans is suitable for automated large-scale production of canned meat, canned fish, canned aquatic products, canned fruits and vegetables, etc. This machine has the characteristics of stable operation, high vacuum degree, and sealing quality that meets standards. The key components are processed using ultra high precision equipment, especially for the phenomenon of unqualified corner sealing in most irregular cans, which is precisely optimized and adjusted to ensure the continuous stability of the whole machine operation and sealing quality.

1、 Mechanical structure part 1) Safety device part:

1. Can lid linkage control device: When a can body enters, a corresponding can lid is allocated. If there is no can, no lid is needed

2. 'No lid shutdown': When an error occurs and the can lid is not allocated, the electric eye recognizes the absence of a lid and automatically shuts down to prevent the can from getting stuck due to the sealing caused by the absence of a lid

3. Safety clutch device: When the transmission fails and exceeds the load, it can interrupt the transmission and stop the tank feeding

2) The six fork can mold is used to vacuum and seal the can with the can entering the main engine head. Customized with high-precision user can shape

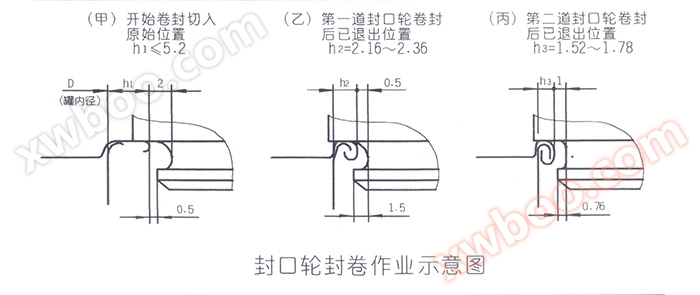

3) Pressure head mold, sealing wheel and sealing principle:

1. The head mold and sealing wheel of this machine are both made of high-quality steel with ultra-high precision machining, and are subjected to vacuum heat treatment to make the head mold precise and the sealing wheel have a long service life

2. The service life of the sealing wheel can reach 200000 to 300000 cans.

3. We can make special material rollers (such as stainless steel, wire mesh, etc.) specifically for customers' requirements

4. Overview of sealing wheel rolling operation:

2、 Main technical specifications

Production capacity: 35-40 cans/sealed cans

Scope:

The maximum diameter of the outer circle of the can shape is 175 millimeters

The maximum diameter of a circular can is 153 millimeters

The maximum width of the can shape is 132 millimeters

Minimum can width: 50 millimeters

Outer height of the tank: 35-130 millimeters

Rated power: 2.2 kilowatts

Dimensions (length x width x height) -------2500x1555x2200 millimeters

Weight of the host (approximately) --------------------------------------------2000 kilograms

3、 Picture of sealed sample canister