VIP member

Form 3L Industrial 3D Printer

The Form3L printer is suitable for 3D printing of medium-sized workpieces. As a cost-effective large-scale 3D printer, it is easy to use and trusted b

Product details

The Form 3L printer is suitable for 3D printing of medium-sized workpieces. As a cost-effective large-scale 3D printer, it is easy to use and trusted by professionals to achieve fast delivery of industrial grade components.

Form 3L also uses advanced LFS printing technology. Low Force Stereolithography (LFS) 3D printing is a more advanced SLA printing technology that uses linear illumination and a flexible tank to cure the resin. This advanced stereolithography form can greatly reduce peel force, providing revolutionary printing quality and printer reliability.

Form 3L also uses advanced LFS printing technology. Low Force Stereolithography (LFS) 3D printing is a more advanced SLA printing technology that uses linear illumination and a flexible tank to cure the resin. This advanced stereolithography form can greatly reduce peel force, providing revolutionary printing quality and printer reliability.

Automation brings high efficiency

No specialized technicians are needed for printing. Form 3L provides an automatic resin filling system, simple print separation software, and an interface that everyone in the company can use.5 times the molding volume

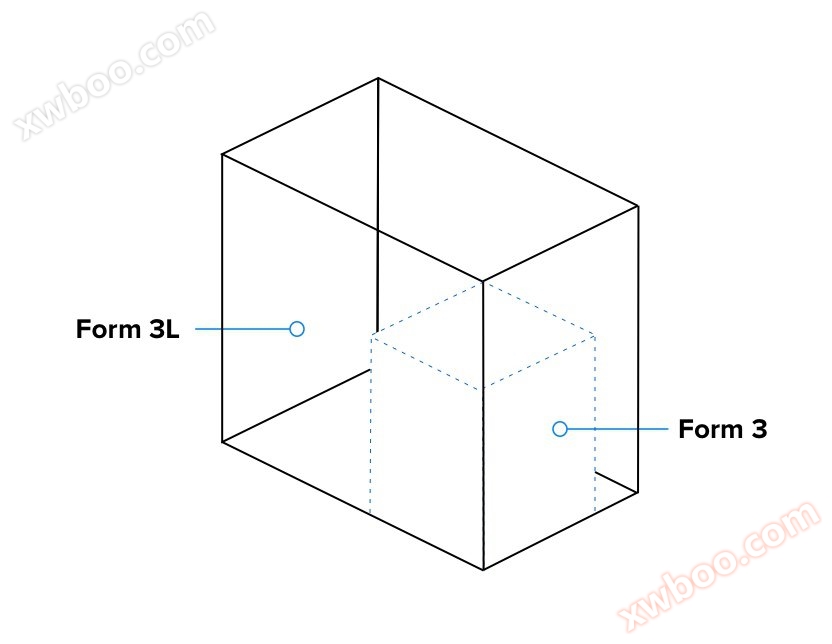

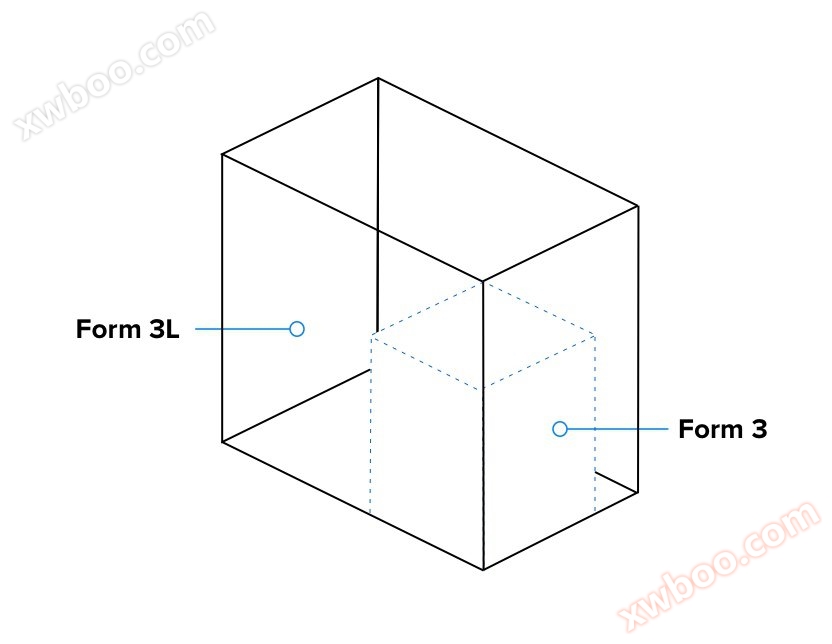

Form 3L has five times the molding volume of Form 3 and can print 500% larger than Form 3.

Faster printing

Form 3L is equipped with two laser modules, Light Processing Units, which can print large, solid parts faster at the same time.Powerful and reliable printing process

Form 3L is also developed based on the Low Force Stereo lithography printing process, continuing the industrial quality, usability, reliability, and flexibility of Formlabs products.

Device compatibility

The resin box is universal on both Form 2 and Form 3. LPU (Laser Module) is also compatible with Form 3 and Form 3L.

Available materials

1. DURABLE RESIN is resistant to mild friction and wear

Durable Resin has low modulus, high elongation, and high impact strength, and can print smooth and glossy surfaces with high resistance to deformation. Use this material for applications that require minimal friction as much as possible.

2.DRAFT RESIN , Realize true rapid prototyping design

Draft Resin is our fastest printing material, suitable for fast printing of large components. Its layer height is 300 microns, which is sufficient to meet the requirements of prototype design and achieve faster design iterations.

3.HIGH TEMP RESIN, High thermal stability

The hot deformation temperature (HDT) of High Temp Resin is 238 ° C @ 0.45 MPa. It is the type of Formlabs resin with the highest thermal deformation temperature. It can be used to print fine prototypes with high heat resistance.

4.FLEXIBLE RESIN, Used for hard and flexible components

A type of 80A Shore hardness material suitable for harder flexible components, with a matte black soft touch. Choose Flexible Resin to create ergonomic features for larger assemblies.

5. Castable Wax Resin

This wax filled resin material is tailor-made for reliable direct investment casting, clean and burn out, with no ash residue. The printed components are suitable for customization, trial production, and final production of jewelry.

6. Standard Resins, High detail prototyping and assembly

The matte finish of Standard Resins can excellently showcase every detail, making it an ideal material for quickly and affordably making jewelry prototypes. It is sturdy enough to not easily break when picked up, worn, or even shipped to customers. This material is very suitable for cheap customized accessories, allowing customers and designers to determine the prototype before casting. This material comes in four colors: gray, black, white, and transparent.

Online inquiry