Principle, structure

An instrument that measures volumetric flow by detecting the effect of fluid flow on an ultrasonic beam (or ultrasonic pulse). The external mounted ultrasonic flowmeter consists of a host and an external mounted sensor. By simply attaching the sensor to the surface of the pipeline, various liquid flow measurements can be completed. Unlike other types of flowmeters, it does not require pipe or flow interruption and is easy to install.

application

Widely used in industries such as tap water, heating, water conservancy, metallurgy, chemical industry, machinery, energy, etc., it can be used for production monitoring, water balance debugging, heat network balance debugging, and energy conservation monitoring.

characteristic

The optimal choice for new large-scale pipelines without real flow verification parameters

● Measurable non-conductive liquids

The measurement of DN15~DN6000mm pipelines can be completed by a set of hosts and several pairs of sensors in combination

● No flow obstruction measurement, no pipeline pressure loss

● Automatically remember the cumulative flow rate of the previous 512 days, 128 months, and 10 years, automatically remember the power on/off time and flow rate of the first 64 times, and automatically remember whether the working status of the flowmeter is normal for the first 32 days

● Support heat measurement, equipped with temperature sensors, can achieve heat measurement.

● Supports SD card storage for data storage.

Technical Parameter

| host | |||||

| Principle: | Ultrasonic Time Difference Principle | ||||

| Accuracy: | be better than±1% | ||||

| Display: | Connectable2×10Backlight type or2×20Character LCD display | ||||

| Signal output: | 1 Road4~20mACurrent output, impedance0~1K,accuracy0.1% | ||||

| 1 RoadOCTPulse output (pulse width)6~1000ms, default200ms) | |||||

| 1 relay output | |||||

| Signal input: | 3 routes4~20mAcurrent input,accuracy0.1%, | ||||

| Can collect temperature, pressure, liquid level and other signals and display them (limited)FU30A) | |||||

| Can connect three wire systemPT100Platinum resistance for heat measurement | |||||

| Data interface: | quarantineRS485Serial interface, supportsMODBUSagreement | ||||

| Application pipeline | |||||

| Pipe: | Steel, cast iron, copper, aluminum, etc., with lining allowed | ||||

| Cement pipesPVCFiberglass reinforced plastic | |||||

| Straight pipe section: | upstream10D, downstream5D, from the pump outlet30D(DFor the application of pipe diameter) | ||||

| Tube inner diameter: | 15~100mm(FitterKU1,KUH1sensor) | ||||

| 50~700mm(FitterKU2,KUH2sensor) | |||||

| 300~6000mm(FitterKU3,KUH3sensor) | |||||

| work environment | |||

| Temperature: | Host -20~60 ℃; Sensor: -30~160 ℃ | ||

| Humidity: | Host 85% RH; flow sensor: capable of working in water with a depth of less than 2m (note: after the sensor is glued) | ||

| Power Supply: | DC8~36V or AC85~264V | ||

| power waste: | 1.5W | ||

| Measurement medium | |||

| Temperature: | Temperature: -30~160 ℃ | ||

| Temperature: -30~160 ℃ | |||

| Turbidity: | 10000ppm with low bubble content | ||

| Current Speed: | 0~±10m/s | ||

| Applicable medium: | water | ||

| seawater | |||

| Pre treated wastewater | |||

| acid liquor | |||

| lye | |||

| Alcohol, beverages | |||

| oils | |||

Measurement composition diagram

FU30A Wall mounted

FU30B cabinet mounted tray type

FU30C cabinet mounted tray type

FU30D - On site online type

FU10 Handheld

FU20- Portable Printing Type

Standard flow sensor

High temperature flow sensor

Bracket type flow sensor

SD card storage optional

The SD card data storage realizes massive storage of ultrasonic flowmeter measurement data, solving the problem of inconvenient storage, reading and processing of wall mounted flowmeter measurement data. It can completely replace manual stopwatches and paperless recorders

The measurement data can be processed using the following four types of "traffic data analysis and statistical software" Including functions such as tabulation, statistics, data analysis, printing reports, and creating flow curves

Raw data recorded by SD card

Software import data

Instantaneous flow curve generated by software

Cumulative traffic bar chart generated by software

Model Selection Table

| FU10- | Handheld external clamp ultrasonic flowmeter | ||||||||||

| FU20- | Portable printed external clamp ultrasonic flowmeter | ||||||||||

| FU30A- | Wall mounted external clamp type ultrasonic flowmeter | ||||||||||

| FU30B- | Disk mounted external clamp ultrasonic flowmeter | ||||||||||

| FU30C- | External clamp type ultrasonic flowmeter (explosion-proof functional type) | ||||||||||

| internet traffic sensor |

|||||||||||

| KU1 | Standard small DN15~DN100 | ||||||||||

| KU2 | Standard medium-sized DN50~DN700 | ||||||||||

| KU3 | Standard large DN300~DN6000 | ||||||||||

| KUH1 | High temperature small DN15~DN100 | ||||||||||

| KUH2 | High temperature medium DN50~DN700 | ||||||||||

| KUH3 | High temperature large DN300~DN6000 | ||||||||||

| BU1 | Bracket standard small DN15~DN100 | ||||||||||

| BU2 | Bracket standard medium-sized DN50~DN700 | ||||||||||

| BU3 | Bracket extension type DN300~DN6000 | ||||||||||

| BUH1 | Bracket high temperature small DN15~DN100 | ||||||||||

| BUH2 | High temperature medium-sized bracket DN50~DN700 | ||||||||||

| BUH3 | Bracket high temperature extension type ≥ DN300 | ||||||||||

| Signal cable length | |||||||||||

| 5 | Standard 5-meter cable (each group includes 2 5-meter cables) | ||||||||||

| X | The unit is meters (X represents the required cable length on site) | ||||||||||

| (Special alternative) VARIO | |||||||||||

| /SD | SD card data storage and computer reading software (FU30 series optional) | ||||||||||

| /P1 | IP68 high protection instrument protection box (portable type) | ||||||||||

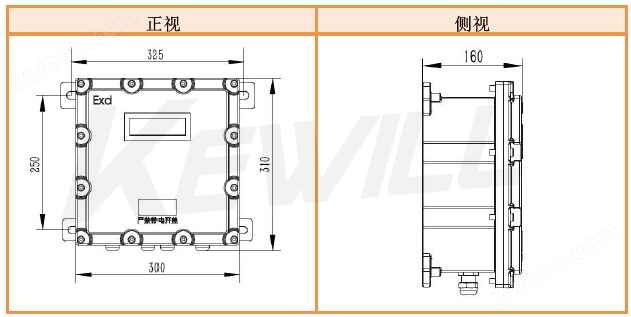

| /P2 | IP65 instrument host protective box (fixed fire-resistant plastic version) | ||||||||||

| /P3 | IP65 instrument host protective box (fixed type 304 stainless steel version) | ||||||||||

| (Special backup option for cold and heat measurement) VARIO | |||||||||||

| /TK-MINI | External temperature sensor (suitable for metal pipes without insulation layer) | ||||||||||

| /TK61 | Plug in temperature sensor | ||||||||||

| /TK61P | Inserted temperature sensor with pressure installation | ||||||||||

| /TP21 | Small caliber temperature sensor | ||||||||||

| FU- | KU1 | 5 | /P1 | /TP21 | ← Selection Example | ||||||

Temperature sensor optional

| type | model | measuring range | temperature range | INSTALLATION REQUIREMENTS |

| PT100 External Adhesive (Three Wire System) | TK-MNI | ﹥DN50 | ﹣40~160℃ | No need to cut off the current |

| PT100 insertion temperature sensor (three wire system) | TK61 | ﹥DN50 | ﹣40~160℃ | Need to cut off the flow |

| PT100 pressure installation with inserted temperature sensor (three wire system) | TK61P | ﹥DN50 | ﹣40~160℃ | No need to cut off the current |

| Small caliber PT100 insertion temperature sensor (three wire system) | TP21 | ﹤DN50 | ﹣40~160℃ | Need to cut off the flow |

About coupling agents

Short term measurements can be made using butter (with good acoustic properties) or lipids such as Vaseline.

Long term measurement can be done with silicone grease and silicone gel

High temperature measurement can be carried out using silicone grease or high-temperature coupling agents.

About installation method

External clamp sensors have V-shaped and Z-shaped installation methods.

Normally, when installing pipelines with an inner diameter ranging from DN15 to DN40, the V-shaped installation method is preferred. When the signal strength of the V-shaped installation method is poor, it can be replaced with the Z-shaped installation method.

When installing pipelines with an inner diameter above DN40, the Z-type installation method can be prioritized. When the pipeline material is cast iron, the Z-type installation method should be preferred.

V-shaped installation method

Align a pair of sensors horizontally during installation

Z-type installation method