Principle, structure

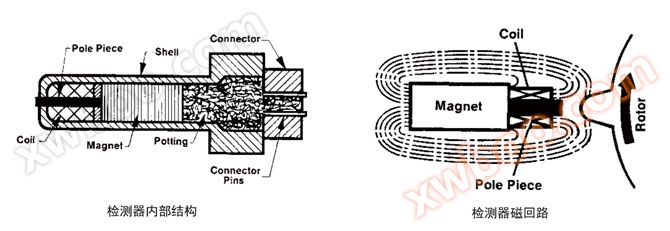

Turbine flowmeter is a type of velocity flowmeter. As shown in the figure below, a turbine is placed at the center of the pipeline, supported by bearings at both ends. When the fluid passes through the pipeline, it impacts the turbine blades, generating a driving torque on the turbine, causing it to overcome friction torque and fluid resistance torque and rotate Within a certain flow range, for a certain viscosity of the fluid medium, the rotational angular velocity of the turbine is proportional to the fluid flow velocity Thus, the fluid velocity can be obtained by the rotational angular velocity of the turbine, and the fluid flow rate through the pipeline can be calculated.

characteristic

● Install high reliability long-life bearings

Excellent repeatability, suitable for ingredients

Excellent low flow velocity measurement performance

Extremely fast response, suitable for use in batch control and proportioning control scenarios

Multi blade structure rotor with high precision

● Steam cleaning is allowed

Equipped with high and low alarm function, it can drive relays

● Equipped with 10 point nonlinear correction function

Standard RS485 communication (MODBUS protocol)

Modular circuit design and rich self diagnostic functions, easy to maintain

● Compact type suitable for equipment installation

| Applicable medium temperature for bearing types | ||

| Bearing material | temperature range | purpose |

| 440C stainless steel ball bearing | ﹣40℃ to 120℃ | Non aqueous medium |

| Ceramic journal bearings | ﹣75℃ to 120℃ | liquid |

| Graphite journal bearing | ﹣75℃ to 160℃ | liquid |

| Tungsten carbide journal bearing | ﹣50℃ to 180℃ | liquid |

application

Finished oil, light crude oil, gasoline, light oil, jet fuel, light diesel, naphtha, ethylene, etc

Lubricating oil, hydraulic oil, etc

● Water, pure water, distilled water, deionized water, desalinated water, softened water, etc

Alcohol, benzene, toluene, xylene, butadiene, carbon tetrachloride, methylamine, acrylonitrile, etc

Formaldehyde, oxalic acid, caustic soda, carbon disulfide, etc

Milk, coffee, etc

High temperature media such as thermal oil and kerosene

Selection Guide

|

|

|

| FR80 flange type | FR80 sanitary clamp type | FR80 thread type |

| Caliber: DN10~DN250 | Caliber: DN15~DN50 | Caliber: DN4~ DN50 |

| Equipped with self-lubricating bearings | Equipped with self-lubricating bearings | Equipped with self-lubricating bearings |

| Accuracy: ± 0.5%/± 0.2% | Accuracy: ± 0.5%/± 0.2% | Accuracy: ± 0.5%/± 0.2% |

| Power Supply: AC 85~ 265 V | Power Supply: AC 85~265 V | Power Supply: AC 85 ~265 V |

| DC 16~36V | DC 16 ~36V | DC 16~36V |

| Output: 4-20 mA, pulse | Output: 4-20 mA, pulse | Output: 4-20 mA, pulse |

| Equipped with two sets of normally open contact output drivers: | Equipped with two sets of normally open contact output drivers: | Equipped with two sets of normally open contact output drivers: |

| Driver: 24V DC, Current<30 mA | Driver: 24V DC, Current<30 mA | Driver: 24V DC, Current<30 mA |

| Communication: RS485 (Modbus) | Communication: RS485 (Modbus) | Communication: RS485 (Modbus) |

| Equipped with 10 point non-linear correction function | Equipped with 10 point non-linear correction function | Equipped with 10 point non-linear correction function |

| Equipped with density setting function and mass unit capability | Equipped with density setting function and mass unit capability | Equipped with density setting function and mass unit capability |

| Low flow rate of 0.1m/s | Low flow rate of 0.1m/s | Low flow rate of 0.1m/s |

| Quick response type, response time 50ms | Quick response type, response time 50ms | Quick response type, response time 50ms |

Technical Parameter

| performance parameter | |

| Accuracy: | 0.5% of rate and 0.2% of rate |

| Repeatability: | ± 0.1% of the measured value |

| Response time: | Maximum 50 milliseconds relative to input change |

| Stability: | Stability for more than 6 months is ± 0.1% of the measured value |

| The impact of environmental temperature: | Exceeding the working temperature range is ± 0.25% |

| The impact of installation location: | If the sensor is fully loaded and there are sufficient straight pipe sections in front and behind, the installation will not be affected |

| Start time: | Starting from zero traffic takes 50 milliseconds |

| Preheating time: | It takes 5 minutes from power transmission to reaching the rated measurement accuracy |

| Sensor parameters | |

| Size: | DN4 to DN250 |

| Temperature range of the tested fluid: | -29 to 120℃; - 29 to 300 ℃ (high temperature customized type) |

| Sensor body material: | AISI 304 SST, Can choose 316L |

| Material of impeller and accessories: | AISI 304 SST, Can choose 316L |

| Ball bearing material: | 316L SST bearings or ceramic bearings |

| Process connection: | DIN PN10 to PN63 |

| Coil impedance: | 1600 ohm |

| Converter parameters | |

| Environmental temperature range: | -20 to 140° F (-29 to 60 ℃ ) |

| Converter shell material: | Low copper die cast aluminum Nema 4X, IEC60529 IP66 (standard), customizable stainless steel converter housing |

| Converter sealing ring: | rubber |

| Power Supply: | AC 86 to 265V, 50/60HZ, 1A quick fuse; DC 16.8V to 31.2V, 1A quick fuse; Or powered by a 3.6V battery |

| Communication protocol: | RS485 communication (MODBUS protocol) |

| Protection level: | IP65&IP68 |

| Electrical interface: | 2 PG13.5 |

| Power: | 3W |

| Output: | 4 to 20 mA current output (for instantaneous flow), pulse output (for total flow) |

| Equipped with high and low alarm outputs, two sets of normally open contacts, driving capability: 24VDC, 30mA | |

FR80 index parameters

| component | describe |

| 1A \\ 1B \\ 1C \\ 1D | Sensor casing |

| 2 | locating ring |

| 3 | Locknut |

| 4 | Signal line connector |

| 5 | Detection probe |

| 6 | support |

| 7 | Impeller and bearing components |

FR80 sensor size and flow range

| Size (mm) | Flow range | Size (mm) | Flow range | ||||||||||||||||

| Minimum m ³/h | Maximum m ³/h | Minimum m ³/h | Maximum m ³/h | ||||||||||||||||

| 4 | 0.005 | 0.317 | 50 | 0.71 | 49.5 | ||||||||||||||

| 6 | 0.01 | 0.712 | 65 | 1.2 | 84 | ||||||||||||||

| 10 | 0.028 | 1.978 | 80 | 1.81 | 127 | ||||||||||||||

| 15 | 0.064 | 4.5 | 100 | 2.83 | 198 | ||||||||||||||

| 20 | 0.113 | 7.9 | 125 | 4.42 | 309 | ||||||||||||||

| 25 | 0.177 | 12.4 | 150 | 6.36 | 445 | ||||||||||||||

| 32 | 0.289 | 20.3 | 200 | 11.3 | 792 | ||||||||||||||

| 40 | 0.452 | 31.7 | 250 | 17.67 | 1236 | ||||||||||||||

FR80 turbine flowmeter converter

| Model | Function | casing | |||||||||||||||||||

| FR80-AC | Power Supply: AC 86 to 265 V; LCD display; Equipped with 4 to 20mA output, pulse output, and RS485 communication; Equipped with high and low alarms | die-casting aluminum | |||||||||||||||||||

| FR80-DC | Power Supply: DC 16 to 36 V; LCD display; Equipped with 4 to 20mA output, pulse output, and RS485 communication; Equipped with high and low alarms | die-casting aluminum | |||||||||||||||||||

| FR80-B | Power supply: 3.6V lithium battery, LCD display, no output | die-casting aluminum | |||||||||||||||||||

FR80 flange type external dimensions

| Size (mm) | Flange end face size L (mm) | Outer diameter of flange D (mm) | Height H (mm) | Approximately weight (kg) | ||||||||||||

| PN16 | PN40 | PN16 | PN40 | PN16 | PN40 | |||||||||||

| 10 | 80 | 90 | 90 | 144 | 144 | 3.0 | 3.0 | |||||||||

| 15 | 75 | 95 | 95 | 146 | 146 | 3.0 | 3.0 | |||||||||

| 20 | 85 | 105 | 105 | 151 | 151 | 4.0 | 4.0 | |||||||||

| 25 | 100 | 115 | 115 | 156 | 156 | 4.5 | 4.5 | |||||||||

| 32 | 120 | 140 | 140 | 169 | 169 | 6.0 | 6.0 | |||||||||

| 40 | 140 | 150 | 150 | 180 | 180 | 7.0 | 7.0 | |||||||||

| 50 | 150 | 165 | 165 | 192 | 192 | 9.0 | 9.0 | |||||||||

| 65 | 175 | 185 | 185 | 210 | 210 | 11.0 | 11.0 | |||||||||

| 80 | 200 | 200 | 200 | 224 | 224 | 13 | 13 | |||||||||

| 100 | 220 | 220 | 235 | 244 | 251 | 16.0 | 19.0 | |||||||||

| 125 | 250 | 250 | 270 | 271 | 281 | 23 | 27 | |||||||||

| 150 | 300 | 285 | 300 | 300 | 307 | 31.0 | 37.0 | |||||||||

| 200 | 360 | 340 | 375 | 353 | 370 | 43 | 53 | |||||||||

| 250 | 420 | 395 | 450 | 406 | 433 | 64.0 | 80.0 | |||||||||

FR80 threaded connection type external dimensions

| Size (DN) | End face size L (mm) | Outer diameter of the body (mm) | thread specification | Height H (mm) |

| 4 | 50 | 36 | M30*1.5 | 113 |

| 6 | 50 | 36 | M30*1.5 | 113 |

| 10 | 50 | 36 | M30*1.5 | 113 |

| 15 | 75 | 40 | G1 | 117 |

| 20 | 85 | 44 | G1 | 121 |

| 25 | 100 | 52 | G1-1/4 | 129 |

| 32 | 120 | 58 | G1-1/2 | 134 |

| 40 | 140 | 69 | G2 | 146 |

| 50 | 150 | 81 | G2-1/2 | 158 |

FR80 clamp connection type external dimensions

| FR80 external dimensions clamp connection | |||

| size(DN) | End face sizeL(mm) | Clamp outer diameterD(mm) | heightH(mm) |

| 15 | 75 | 51 | 124 |

| 20 | 80 | 51 | 124 |

| 25 | 100 | 51 | 124 |

| 32 | 120 | 51 | 124 |

| 40 | 140 | 64 | 137 |

| 50 | 150 | 77.5 | 151 |

| 65 | 175 | 91 | 164 |

FR80 installation requirements

FR80 Pressure Loss Curve

Ordering Tips

When placing an order, please specify the flow direction, type, diameter, and expected measurement range of the medium. We can help you complete precise calibration at the factory.

If it is a viscous medium, please indicate the viscosity, temperature, type of medium, and flow range.

Model Selection Table

| FR80- | turbine meter | ||||||||||

| orifice | |||||||||||

| DN4 DN6 DN10 DN15 DN20 DN25 DN32 DN40 DN50 DN65 DN80 DN100 DN125 DN150 DN200 DN250 (special pipe diameters such as DN300 are agreed upon for delivery) | |||||||||||

| output signal | |||||||||||

| Pulse+4 to 20mA current signal | |||||||||||

| Pulse+0 to 5V voltage signal | |||||||||||

| High point low point normally open contact signal (switch value full range setting) | |||||||||||

| Connection method | |||||||||||

| Threaded sealed connection | |||||||||||

| Flange connection | |||||||||||

| Sanitary grade clamp connection | |||||||||||

| Quick sealing hose connector | |||||||||||

| accuracy | |||||||||||

| Accuracy 0.2% (applicable to pipelines above DN15) | |||||||||||

| Accuracy 0.5% (applicable to pipelines above DN10) | |||||||||||

| Accuracy 1.0 | |||||||||||

| Voltage resistance level | |||||||||||

| EN 1092-1(DIN)PN10 | ASME B16.5(ANSI)CLASS150 | ||||||||||

| EN 1092-1(DIN)PN16 | ASME B16.5(ANSI)CLASS300 | ||||||||||

| EN 1092-1(DIN)PN25 | ASME B16.5(ANSI)CLASS600 | ||||||||||

| EN 1092-1(DIN)PN40 | ASME B16.5(ANSI)CLASS900 | ||||||||||

| EN 1092-1(DIN)PN63 | ASME B16.5(ANSI)CLASS1500 | ||||||||||

| EN 1092-1(DIN)PN100 | ASME B16.5(ANSI)CLASS2500 | ||||||||||

| EN 1092-1(DIN)PN250 | JIS 10K | ||||||||||

| EN 1092-1(DIN)PN400 | JIS 20K | ||||||||||

| Special standards for product application areas | |||||||||||

| System power supply mode | |||||||||||

| 12 to 24V DC | |||||||||||

| 86 to 265V AC | |||||||||||

| 3.6V lithium battery (for pulse signal or display selection only) | |||||||||||

| Material of the liquid receiving body | |||||||||||

| Stainless steel 1.4301 (304) | |||||||||||

| Stainless steel 1.4435 (316L) | |||||||||||

| Internal impeller and accessory material | |||||||||||

| 403F stainless steel | |||||||||||

| Stainless steel 1.4435 (316L) | |||||||||||

| Hastelloy C | |||||||||||

| Bearing material | |||||||||||

| Stainless steel 440C ball bearing (non water environment) | |||||||||||

| Ceramic journal bearings | |||||||||||

| Graphite journal bearing | |||||||||||

| Tungsten carbide journal bearing | |||||||||||

| (Special alternative) VARIO | |||||||||||

| Customized with special parameters | |||||||||||

| The above selection table does not include selection codes. If you need selection codes, please contact us or fill in your information | |||||||||||