The freeze-drying technology for extracting anthocyanins from indigo fruit isA natural plant water extraction, separation, concentration and freeze-drying method at room temperature, combined with anthocyanin freeze-drying machine equipment, effectivelyimprovedLonicera edulisextractanthocyaninproductfreeze-dryingdeep processingofApplication,Preserved various nutrients and trace element substances, solving the problem of pollution and damage to nutrients caused by traditional organic solvent extraction freezing.At present, the integrated system of anthocyanin freeze-drying machine has been implementedDa Hinggan LingApply production to enterprises in Ningxia region.

Freeze drying technology for extracting anthocyanins from indigo fruitIt's breaking the wall of indigo fruitsqueezeAfterwards, adoptPurified water extracts substances,pass throughLayer by layer filtration to remove suspended solids, powders, and microorganisms, obtaining purified extraction solutionQuickly proceedCooling down,after thatPerform molecular separation at room temperatureSystem performs cyclic separationThe entire process of separating the extraction solution is controlled at 25~At a temperature range of 30 ℃, the separation rate is 8-10 liters per minute,Remove moisture to achieve highconcentrationExtraction solution. Further prepared with auxiliary materialsAnd homogeneityFreeze dried to become an instant powder that can dissolve immediately in both warm and hot waterAnthocyanins and various nutrientsThermal sensitive raw materialscharacteristicCan be fully maintainedanthocyaninThe product color is consistent with the true active ingredients, and the product does not deteriorate, remain unchanged, or change color.

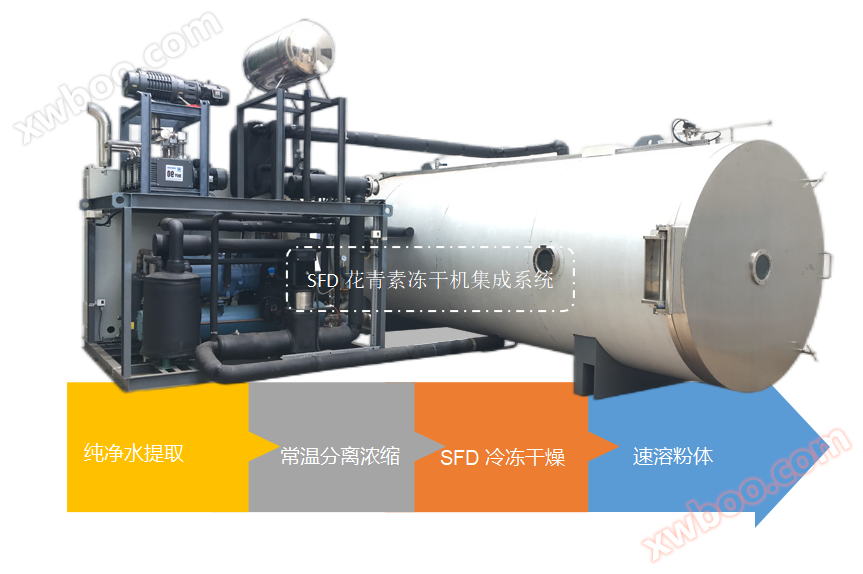

Anthocyanin freeze-drying machine integrationThe system includes a wall breaking and pressing system, a boiler systemCleaning, medicated cleaning, sterilizationSystemFiltration system、condensesystem、Homogenization system, AGV car system, freeze-drying machine system, detection system, weighing and packaging system, etc. are integrated through SFD freeze-drying machine water extraction and room temperature separation system, and are respectively utilizedTechnology of extracting liquid thermal sensitivity and phase change、The technology of maintaining low temperature in the concentration operation systemart、Operation technology for converting concentrated liquid into powder、Powder amplification technology and blending technology、Vacuum freeze-drying technology andDry powder packaging technologyWaiting for production and processing. The SFD freeze dryer water extraction and room temperature separation integrated system is widely used in various natural plant extraction and freeze drying, includingFreeze dried processing of blueberry anthocyanins, freeze-drying of tea polyphenols, freeze-drying of rose anthocyanins, freeze-drying of Ganoderma lucidum extract, and freeze-drying of ginseng extractsaponinFreeze drying and sea buckthorn extractionflavoneFreeze drying, etcProvide technical solutions and turnkey engineering services for complete sets of equipment!