In today's increasingly strict environmental inspections, the installation of explosion-proof valves or dust explosion isolation valves on dust collector pipelines has attracted more and more attention. In the past, we often used to install explosion-proof plates (explosion-proof plates) on dust collectors to release excess pressure caused by dust storm explosions and reduce the possibility of dust collector explosions. But if explosion-proof valves are not installed in the dust collector pipeline, especially in the inlet pipeline, the pressure waves and flames generated by explosions will propagate along the pipeline to the upstream and downstream equipment of the dust collector, causing secondary explosions or multiple explosions, resulting in greater risks.

Dust removal system explosion-proof valve parameters:

Explosion proof valve, gravity based design, no need for sensor triggering, available in normally open and normally closed types;

Applicable: Unidirectional explosion-proof, negative pressure system, horizontal installation;

Applicable dust: St1 and St2 dust with Kst less than or equal to 300 barg * m/s;

Caliber ranges from DN100 to DN1000, with multiple options available;

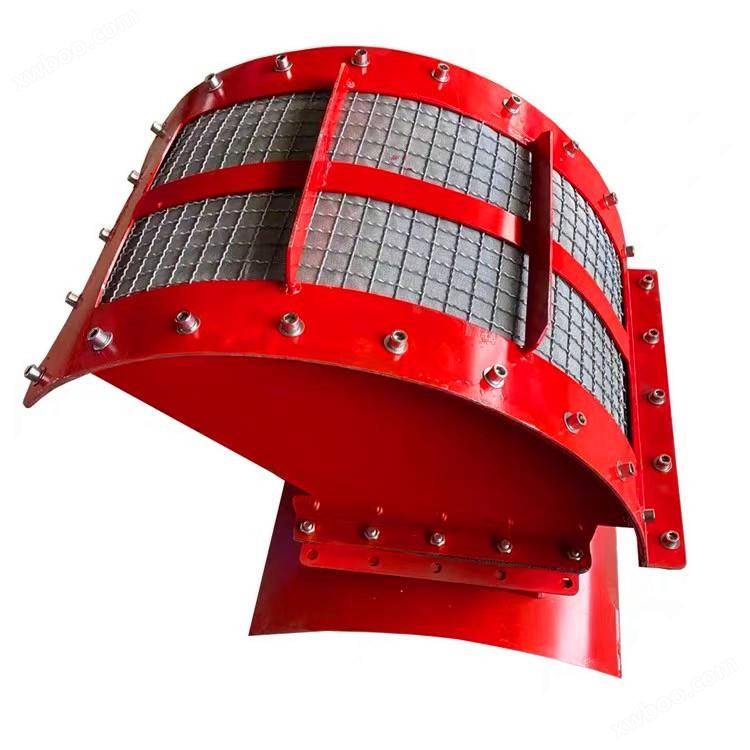

Material: Valve body carbon steel, coating color RAL3000; Valve disc made of stainless steel;

Applicable wind speed: 15-30m/s;

Pressure loss: around 200pa;

Can withstand pressure: 2.0barg@20 ℃;

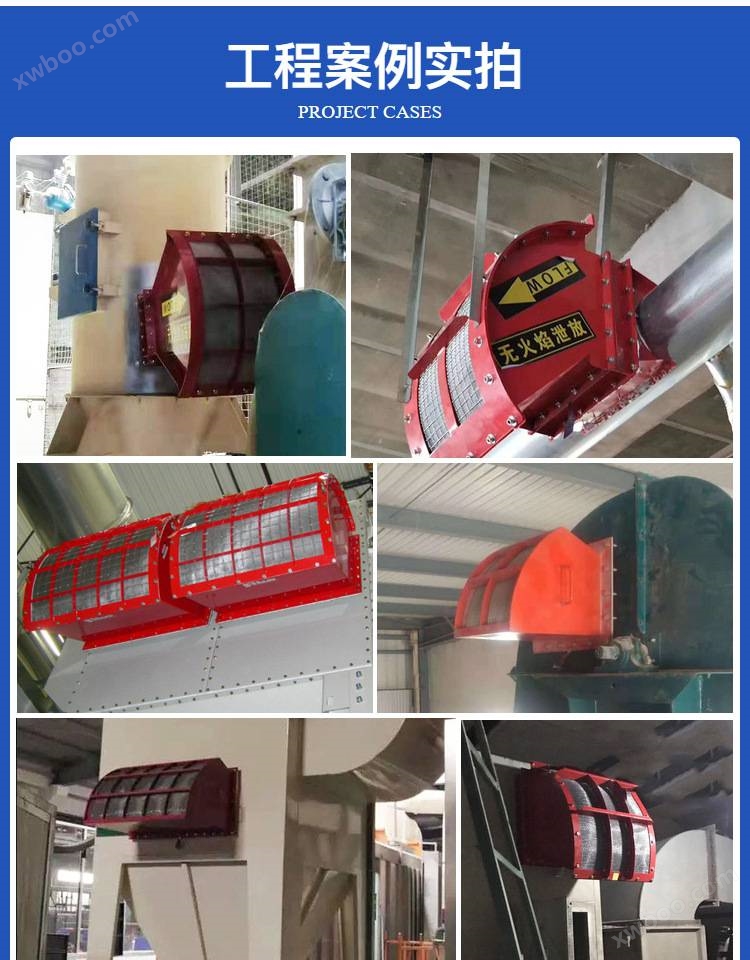

Standard installation method for pipeline explosion-proof valve: horizontal installation, using flange connection;

Installation location: 2-7m from the inlet pipeline of the dust removal equipment;

By integrating sensors to detect operating conditions, longer maintenance times can be allowed;

Durable and sturdy design, allowing for minimal maintenance;

Comes with an inspection cover for easy inspection;

Optional accessories such as signal sensors and closed position indicator switches;

Can provide testing reports from domestic authoritative institutions; Installation standard for pipeline explosion-proof valve

The product has obtained multiple national certifications and can pass through security checks. Accompanying the goods are relevant certificates.

Dust removal system explosion-proof valve - Characteristics of dust explosion-proof valve:

1. Wide applicability

2. Self locking device, adjustable by balance hammer, slight pressure loss

3. The product adopts an anti explosion design with integrated sensors for monitoring, providing millisecond level response

4. Low maintenance cost

5. Applied to the inlet pipe of dust collectors, cyclone separators, and other dust process pipelines

6. The valve disc is designed to be normally open

Principle:

Unidirectional explosion-proof valve is normally used on the inlet pipeline of dust collectors or cyclone separators. It is a simple, economical and reliable explosion-proof product, mainly used to block the flame and shock wave generated after internal explosion of equipment from transmitting to upstream pipelines and equipment. During operation, the valve disc of the one-way explosion-proof valve is opened by the normal working airflow in the pipeline or is in a normally open state. In the event of an explosion inside the protected equipment, the valve disc of the explosion-proof valve is closed due to the impact of the shock wave.

Notes:

Before installing the explosion-proof valve, the dust removal pipeline should be purged of accumulated dust, and the pipeline should be cut according to the size measurement of the explosion-proof valve. Use auxiliary equipment such as cranes for installation, and fix the bracket of the explosion-proof valve.

Preparation by the construction party before construction:

1. Prepare construction tools: plasma cutting machine, polishing machine, pliers, wrench, screwdriver, inflatable drill, hand drill, etc. 2. Prepare the high-altitude homework rope, hat, and gloves.

3. Provide construction personnel with work certificates.

4. Renting scaffolding and cranes.

5. Measure the average wind speed of three dust removal pipelines and record it. Installation location: The explosion-proof valve is about 3-4 meters away from the dust removal equipment.

Installing explosion-proof valves can effectively prevent the spread of explosions, protect adjacent workshops or equipment, and avoid secondary or multiple explosions.

Our main products include one-way explosion-proof valves, flameless venting devices, pipeline spark detectors, and other security products. We can provide installation and technical consultation.

The flameless release device consists of two parts, an explosion-proof board and a fire extinguishing module. The explosion-proof plate responds to the rapid increase in detonation pressure and immediately opens to reduce the pressure. When the expanding fireball passes through the opened explosion-proof plate, it is intercepted by the fire extinguishing module. Stainless steel precision mesh with frame support plays a three-dimensional flame capture role in extinguishing flames. The fire extinguishing module eliminates the flames of detonation, reduces the temperature of hot gases, and captures the combustion and unburned dust passing through the opened explosion-proof plate.

There are three main ways to prevent dust explosions: explosion venting, explosion isolation, and explosion suppression

Explosion relief: By using a pressure relief device to release the explosion in advance, the equipment is protected from damage.

Explosion proof: A type of explosion-proof valve is used to block explosions and prevent flames from spreading.

Explosion suppression: Firstly, the detection device detects the initial spark formed, and then feedback activates the fire extinguishing device to instantly extinguish the fire and prevent the occurrence of an explosion.

Dust removal system explosion-proof valve - Five safety functions of dust explosion-proof valve:

Flame Capture - No flame can escape, providing a safe operating environment.

Eliminate the harm of external secondary ignition and its potential continuous explosion to the equipment.

Dust retention - capturing processed substances and eliminating potential harmful substances from entering the environment.

Eliminate high-pressure buffering explosion pressure peaks, protect personnel and the surrounding environment, including buildings, from the threat of explosion pressure.

Temperature control - absorbs fireballs, but the surrounding environment temperature hardly rises.

Dust conveying pipeline explosion-proof device - Pipeline explosion-proof valve manufacturer price and technical characteristics:

Static opening pressure: 0.01MPa.

Material: Carbon steel/304 stainless steel.

No special maintenance is required.

We can provide an online repair structure that allows for the replacement of venting plates and cleaning of flame arresters without the need to disassemble interfaces.

The flange interface can be customized.

Optional signal output device for real-time monitoring of the working status of the product.

Compliant with EN16009 standard and passed standard testing.

Provide various forms of flameless venting structures to meet the needs of different working conditions.

Working Principle:

When the flame passes through the mesh flame retardant element, the flame retardant element exchanges heat with the flame, quickly cooling the high-temperature flame, releasing pressure and smoke, ensuring that the flame is not spread, thereby causing secondary or multiple explosions. At the same time, the pressure waves or noise generated by the production equipment will also be reduced. In industrial production, the combination of flameless venting devices and explosion-proof valves not only effectively prevents pressure waves and flames from spreading to the production site of upstream workshops, but also suppresses the occurrence of secondary explosion accidents, reduces property losses, and protects personnel safety..

A large amount of solid dust is generated in the industrial production process, which seriously affects the working environment and workers' health. When mixed with air during processing or storage operations, explosion can cause ignition of combustible gases, mist or dust. Rapid pressure rise occurs in a sealed structure, and if there is not enough strength to withstand the burst pressure, it will cause significant losses and casualties. When the dust removal equipment is located indoors and only uses the venting plate to vent, the flames and pressure waves generated by the explosion will be directly released into the work area, which may cause secondary accidents and seriously affect the working environment and worker safety. Therefore, it is very necessary to install flameless venting products in the powder system of the production workshop.

Composition of flameless explosive device:

The flameless explosion-proof device of the dust collector consists of a flame extinguishing template, explosion-proof plates, explosion-proof junction boxes, and clamps.

The explosion-proof core is formed by connecting the shell and the upper cover with square tubes, forming a extinguishing module component. When the plate reacts to the rapidly accumulating explosion pressure and opens to release the pressure, it is intercepted by the extinguishing module as the forming fireball passes through the opened plate. The stainless steel precision mesh screen installed in the stainless steel frame serves as a three-dimensional flame arrester to extinguish flames. The extinguishing module suppresses the flames and hot gases of detonation, as well as the combustion and unburned dust by opening the explosion-proof door. The three-dimensional mesh design can serve as a heat sink, preventing explosions in the middle section and absorbing pressure waves and dust released by the explosion.

Although the temperature of the fireball from a dust explosion can easily reach 1000 ° C, the large surface area of the extinguishing module can quickly cool and maintain at 100 ° C. Below the temperature of C. This makes the temperature changes around the system negligible. Due to its ability to extinguish flames, contain dust, and control pressure and temperature, flameless pressure relief devices can be used in any indoor location where explosion impact needs to be avoided.

Application fields:

Production workshops for artificial boards, wood, and furniture.

The environment of fibers, shavings, and dust generated during the movement of objects such as metals and sand.

The spark environment generated during the operation of high load equipment.

Enterprises that generate high dust environments such as tobacco, chemical, textile, food, feed, metallurgy, leather, rubber processing, etc.

Dust explosion requires five elements, and when these five elements coexist, there is a possibility of explosion occurring. The five elements are as follows: oxygen; Combustible dust; Fire source; Dust cloud; confined space

Dust explosion is accompanied by strong shock waves and flames. Due to the lack of pressure resistance of the equipment, it will be damaged during the explosion, resulting in the risk of secondary or multiple explosions. So we are required to pay attention to dust explosion protection.

In order to prevent equipment from generating dust explosions or to avoid greater harm in the event of dust explosions, explosion-proof pressure relief equipment is particularly important.

Explosion venting is one of the commonly used and effective methods of explosion protection; Release pressure during potential industrial explosions and provide a well-designed pressure release! Flameless discharge flame arrester device

For more installation and technical details, please consult: Jiangxi Century Travel Gansheng

Our main products include flameless explosion-proof devices, explosion-proof valvesPipeline spark detector, inlet and outlet pressure difference alarm,Waiting for security products, we can provide installation and technical consultation