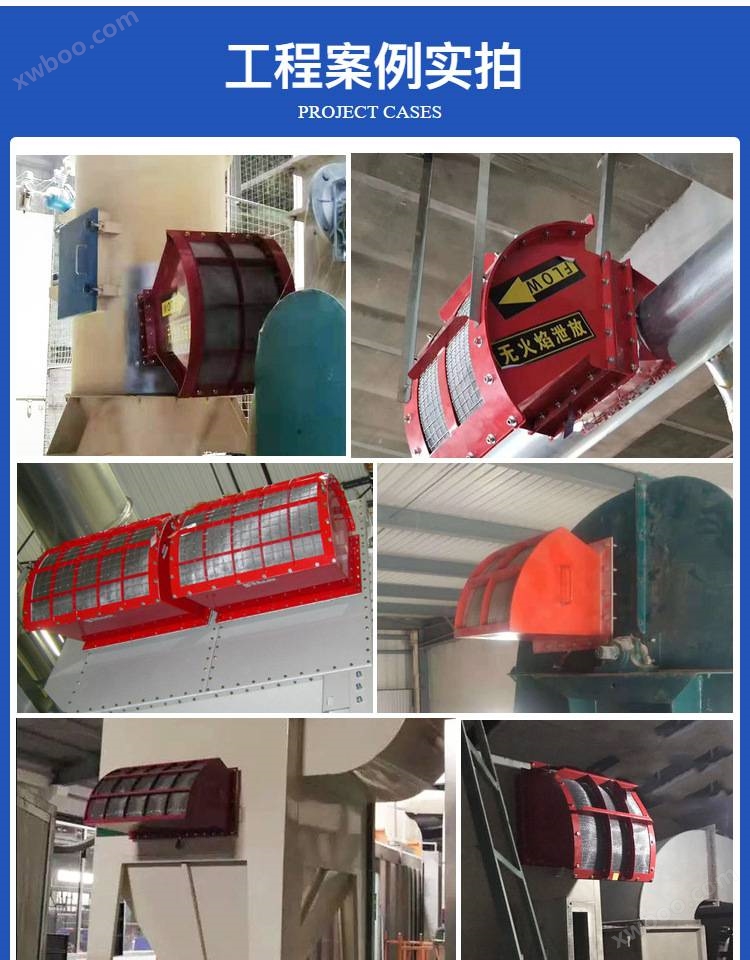

The sales scope of flameless venting devices includes: Shandong Jiangsu Jiangxi Hebei Henan Zhejiang Liaoning Tianjin Gansu Sichuan Guangdong Guangxi Fujian Hubei Hunan Chongqing Yunnan Anhui Ningxia Inner Mongolia Jilin Shanghai Guizhou Xinjiang Shaanxi Shanxi and other parts of the country. Welcome customers from all over the country to call! More installation and technical details,Please consult: Century Travel 【 Gan Gong 】

This device consists of two parts:

1) Explosion relief film;

2) Flame extinguishing module;

Static opening pressure: 0.01MPa.

Material: Carbon steel/304 stainless steel.

No special maintenance is required.

We can provide an online repair structure that allows for the replacement of venting plates and cleaning of flame arresters without the need to disassemble interfaces.

The flange interface can be customized.

Optional signal output device for real-time monitoring of the working status of the product.

Compliant with EN16009 standard and passed standard testing.

Provide various forms of flameless venting structures to meet the needs of different working conditions.

Function of pressure relief valve device for dust removal equipment:

1. Extinguish the burst flame - No burst flame can escape, providing a safe operating environment.

2. Retention and explosion of dust - Capture process materials and eliminate potential harmful substances from entering the environment.

3. Control the bursting pressure - absorb the peak bursting pressure, protect personnel and the surrounding environment from bursting pressure damage.

4. Control the explosion temperature - absorb the explosion fireball and keep the surrounding environment temperature almost unchanged.

Features:

1. No open flame design can effectively prevent huge losses caused by secondary explosion of dust

2. Customized processing according to customer requirements

3. Easy installation, simple hinge design and maintenance

4. Capture processed substances and eliminate potential harmful substances from entering the environment

5. Applicable equipment: dust collector, bucket elevator, drying equipment, cyclone separator, dust collector

6. Can be used in conjunction with explosion-proof valves

Working Principle:

A large amount of solid dust is generated in the industrial production process, which seriously affects the working environment and workers' health. When mixed with air during processing or storage operations, explosion can cause ignition of combustible gases, mist or dust. Rapid pressure rise occurs in a sealed structure, and if there is not enough strength to withstand the burst pressure, it will cause significant losses and casualties. When the dust removal equipment is located indoors and only uses the venting plate to vent, the flames and pressure waves generated by the explosion will be directly released into the work area, which may cause secondary accidents and seriously affect the working environment and worker safety. Therefore, it is very necessary to install flameless venting products in the powder system of the production workshop. When the flame passes through the mesh flame retardant element, the flame retardant element exchanges heat with the flame, quickly cooling the high-temperature flame, releasing pressure and smoke, ensuring that the flame is not spread, thereby causing secondary or multiple explosions. At the same time, the pressure waves or noise generated by the production equipment will also be reduced. In industrial production, the combination of flameless venting devices and explosion-proof valves not only effectively prevents pressure waves and flames from spreading to the production site of upstream workshops, but also suppresses the occurrence of secondary explosion accidents, reduces property losses, and protects personnel safety.

Application fields of pressure relief valve device for dust removal equipment:

Production workshops for artificial boards, wood, and furniture.

The environment of fibers, shavings, and dust generated during the movement of objects such as metals and sand.

The spark environment generated during the operation of high load equipment.

Enterprises that generate high dust environments such as tobacco, chemical, textile, food, feed, metallurgy, leather, rubber processing, etc.

Flameless venting devices are used to protect personnel and equipment from damage caused by flames and dust. During an explosion, flames and dust are emitted into the device. The flame generated by the explosion will be extinguished because it passes through several layers of heat absorbing stainless steel mesh, while the dust barrier captures the vast majority of particles. This enables flameless venting devices to be used indoors or in situations where the explosion propagation path poses a danger to personnel, also known as powder flame arresters.

In today's increasingly strict environmental inspections, safety has attracted more and more attention. In the past, we often used to install a venting plate on the dust collector to release the overpressure caused by dust storms. However, installing indoor equipment in this way is not permitted by the safety supervision department, as it can endanger surrounding personnel and equipment. The pressure waves and flames generated by explosive explosions may cause secondary or multiple explosions, posing greater risks. So using explosion-proof plates alone is unreliable for dust collectors. Therefore, we recommend using flameless venting and isolation technology (which is more economical) or explosion suppression and isolation technology to protect production safety.

Whether you need to purchase or just inquire, whether you are a distributor or a user, we are always consistent. As long as you say "are you there", we will immediately appear in front of you! Even though I have abused you a thousand times, I still spoil you like my first love!

Our company promises to complete the production tasks of the supplied products with quality, quantity, and on time, and promptly deliver the products to the customer's demand site to ensure normal operation.

Full process monitoring: Customers only need one phone call, and the after-sales service department adopts a one-stop mode, comprehensive responsibility system, full process monitoring implementation, and tracking of processing results to ensure customer satisfaction.

Instructions:

1. The above content fully complies with the requirements of relevant standards. Due to product upgrades or discrepancies between pictures and actual machines, please refer to the actual machine. This content is for reference only.

2. If your needs deviate from theirs, please call Sales Century Hang Gan Bingpeng at number 182699. Thank you for your trust and companionship. We cherish this hard won fate.

Thank you for your trust and company. This hard won fate is something we cherish。