Spark catcher, when we hear this name, we think what kind of machine it is. The so-called spark arrester is a common safety device on industrial pipelines, mainly used to protect the dust collector and prevent accidents such as bag or cylinder burning in the subsequent bag or filter dust collectors. It has a wide range of industrial applications. Next, Century Travel Gan Gong will take you to learn about spark arresters!!!

Dust removal Mars catcher (swirl spark catcher) Introduction:

1. Spark catcher, as the name suggests, is a device that captures sparks and extinguishes them.

2. Laser cutting, robot continuous welding, and metal cutting and polishing generate a large amount of splashing sparks.

3. When a large number of continuous splashing sparks are generated, they enter the dust collector directly through the exhaust duct of the dust collector.

4. The dust collector is equipped with filter material, and encountering a continuous large number of sparks and sparks on the surface often causes fire accidents.

5. Even if flame-retardant filter material is used, a large amount of sparks can burn the surface of the filter material, causing filtration failure and powder leakage.

6. The filter material is the heart of the dust collector. Once it fails and leaks powder, it is scrapped and needs to be replaced with a new filter material, causing serious economic losses.

7. The pipeline type spark arrester, originating from European and American technology, is specifically developed to address the safety issue of the inability to extinguish sparks during the induced draft process of the old air duct layout.

Structure description:

1. It includes a hollow shell with air outlets and air inlets at both ends. The cross-sectional area of the shell is larger than that of the air inlet. Multiple layers of capture nets are installed inside the shell, and the aperture of the capture nets increases from front to back.

2. Multiple partitions are inserted into the anti splash baffle shell, and the partitions are equipped with through holes. The through holes of each partition are arranged in a staggered manner. Several guide vanes are installed on the partition to guide the exhaust gas and intercept and capture the powder on the partition. The partition blades have certain wear-resistant measures and appropriate rotation angles;

3. Spark catcher mechanism: 1. Screening effect, 2. Inertial collision, 3. Diffusion effect, 4. Intercepting effect. The various trapping mechanisms mentioned above are not all effective for Mars with the same characteristics at the same time. The dominant mechanism is often only one mechanism or a combination of two or three mechanisms. Its dominant role should be determined based on the actual conditions such as the properties, structure, characteristics, and operating conditions of Martian dust particles.

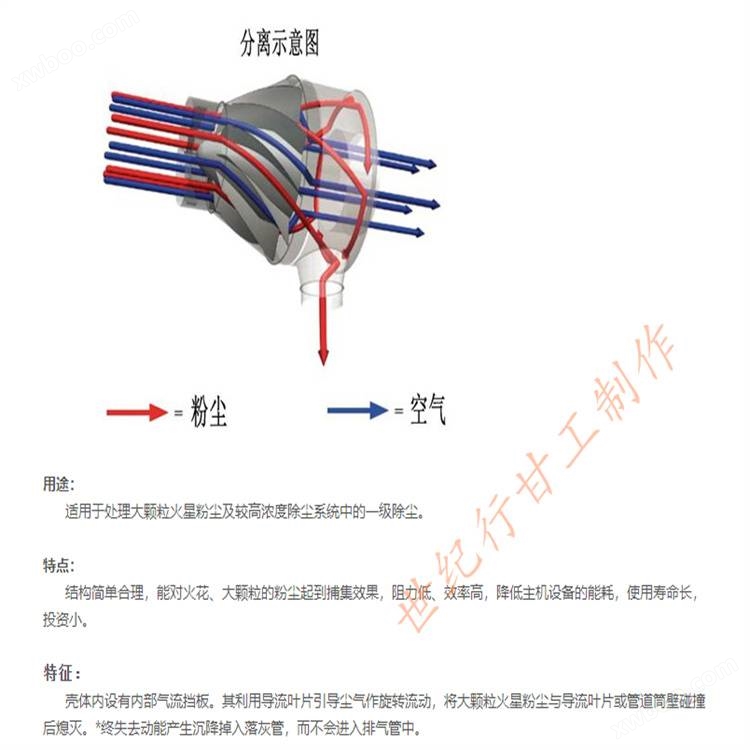

4. Using rotating guide vanes to guide the smoke to rotate and flow, the Martian dust is extinguished after colliding with the guide vanes or pipe walls. There is an internal airflow baffle inside the shell, which is equipped with C-shaped steel.

Working principle of dust removal Mars catcher (swirl spark catcher):

When sparks pass through the specially constructed airflow guide plate inlet, due to the principles of aerodynamics, a cyclone will be generated, completing the process of collision, extinguishing, settling, and export in a special structural channel.

Scope of application:

Class A: Welding fumes generated during the construction of secondary protection welding and argon arc welding, and sparks generated during the work of spark cutting. Mainly smoke, with a small amount of dust

Class B: working conditions with high temperature, biomass boilers, melting furnaces, multiple sparks, and easy reignition. This type of fire catcher is based on the normal temperature spark catcher and requires additional upgrades to the necessary mechanisms, such as installing a star shaped discharge net to continuously scrape sparks and sparks into the collection bucket. At the same time, it effectively prevents flammable substances from colliding and extinguishing, and can reignite and cause fires at high temperatures.

The operating conditions and configurations of Class A and Class B are different, so when selecting, it is necessary to understand the detailed actual production conditions of the user.

The main function of the dust removal spark catcher (swirl spark catcher) is to treat some high-temperature and spark containing flue gas, eliminate sparks in the flue gas, and avoid burning the filter bag of the bag filter.

There are various structural forms of spark arresters, including swirl type, louver type, gravity settling type, etc.

1. The swirl type capture method uses swirl type guide vanes to guide the flue gas to rotate and flow, and extinguishes large particle Martian dust after colliding with guide vanes or pipe walls.

2. Gravity settling type uses a pipeline to pass the flue gas to the bottom of the cylindrical settling chamber, and then the flue gas passes through the wall to settle the sparks, and the remaining exhaust gas is discharged to the dust collector process.

3. Loubet style, a simple barrier method.

If choosing gravity settlement, it is necessary to ensure that the cross-sectional flow velocity is controlled below 3m/s, and the diameter of the device cylinder is about 11-12m. There is no installation space on site for this. The swirl type is a cylindrical device coaxial with the pipeline, mainly using inclined guide vanes arranged radially inside the cylinder to make the particles have a high radial movement tendency, and slide along the cylinder wall under the axial airflow to the outlet end dust collection ring. The gas flows out from the outlet center, and the particles fall into the bottom ash hopper of the dust collection ring. The device has a moderate length and a wide range of applications. Let's take a detailed look below!

The Mars trap is generally installed before the inlet of the dust collector, including a housing, with inlet and outlet ports on both sides of the housing. The lower part of the shell is connected to the ash collection bucket, and the lower part of the ash collector is equipped with an ash discharge mechanism. The shell is installed on the bracket. The Mars trap is mainly composed of air ducts, shafts, small shafts, diaphragms, and rotating guide vanes, supported on the air outlet through bearing seats. When the wind speed is constant, the movable guide vanes installed on the small shaft automatically change their deflection angle with the change of speed. Forming a baffle at the outlet of the flue can control and adjust the exhaust speed, collide and extinguish sparks, and play a role in fire prevention. It is an economical and ideal flue fire prevention device. It has the advantages of high spark rate, simple structure, no need to increase system resistance, long service life, and low investment.