Product Introduction of Diesel Engine Deep Well Fire Pump

The XBC diesel engine deep well fire pump set manufactured by Nanjing Huanya Pump Co., Ltd. is a fire pump set introduced and developed in accordance with the new Chinese fire pump standard GB6245-2006 "Fire Pump Performance Requirements and Test Methods" and the American Fire Protection Association standard NFPA20. The product has undergone type testing by the China Fire Equipment Quality Supervision and Testing Center, and all performance indicators have met the standard requirements, obtaining the Fire Product Certification.

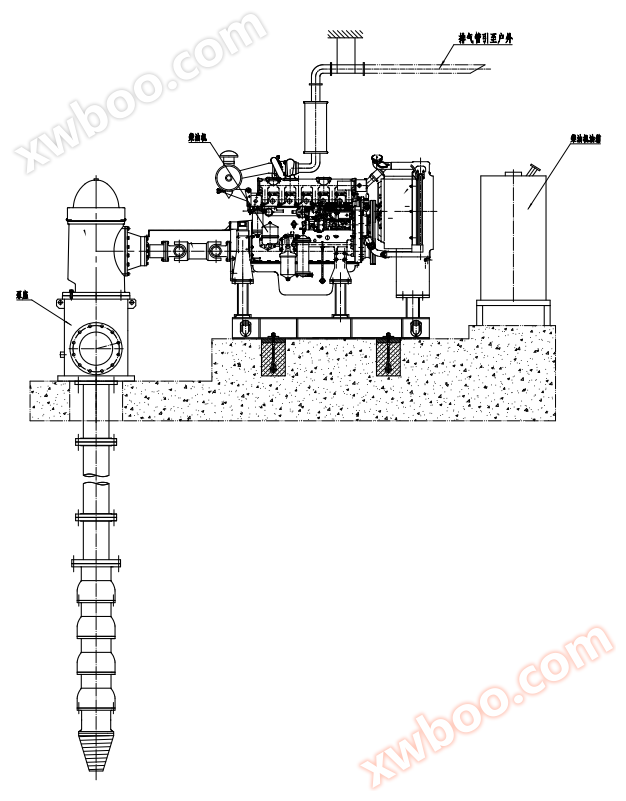

The diesel engine deep well fire pump set consists of multiple centrifugal impellers and guide shells, lifting pipes, transmission shafts, pump seats, gearboxes, diesel engine assemblies, control cabinets, and other components. The pump seat, gearbox, and diesel engine assembly are located above the wellhead. The power of the diesel engine assembly is transmitted to the impeller shaft through a transmission shaft concentric with the lifting pipe via the gearbox, thereby generating flow and pressure.

Application scope of diesel engine deep well fire pump

XBC diesel engine deep well fire pump is mainly used for fire hydrant extinguishing, automatic sprinkler extinguishing and other fire protection systems in fixed fire protection systems such as industrial and mining enterprises, engineering construction, high-rise buildings, etc. It can be used to transport clean water without solid particles and media with chemical properties similar to water. It can also be used for shared water supply systems in daily life, production, buildings, municipal water supply and drainage, docks, offshore platforms and other places without power supply.

Internal structure of diesel engine deep well fire pump

a) Gearbox: Hollow shaft gearbox for deep well pumps (H-type);

b) Adjust the nut: Adjust the axial displacement of the impeller;

c) Pump seat: capable of withstanding heavy loads and facilitating the installation of packing boxes;

d) Pre lubrication plug: Before starting, inject clean water through this area to lubricate the internal bearings of the water pump;

e) Upper short pipe (short pipe B): connected by flange, the upper flange of the short pipe is connected to the pump seat, and the lower flange is connected to the flange of the lifting pipe;

f) Wheel shaft: 2Cr13 stainless steel;

g) Mid shell: Smooth flow channel reduces frictional resistance and improves efficiency. Materials: QT450, 2Cr13, 304, 316, etc;

h) Impeller: Designed in conjunction with the middle shell, it is efficient, has a wide operating range, and undergoes precise balancing to ensure smooth operation. Material: Silicon brass QT450、2Cr13、 304, 316, etc;

i) Medium shell bearings: Copper bearings or wear-resistant rubber bearings. Reliable work and long lifespan.

j) Cone sleeve: securely fix the impeller onto the impeller shaft.

k) Lower shell bearing: Copper bearing, grease filled, long-term trouble free operation.

l) Lower shell: Guide the liquid in the water filter evenly towards the impeller with minimal loss. Materials: QT450, 2Cr13, 304, 316, etc;

m) Water filter: The length of the water filter should be appropriate and can prevent large particles from entering the water pump;

n) Drive shaft: High strength carbon steel, chrome plated on the surface of the bearing position. Stainless steel material can be provided as needed;

o) Lifting pipe: Lifting pipes can be installed using threaded connections or flange connections.

Installation and use of diesel engine deep well fire pump

Unit installation and usage instructions

1. Installation

Before installing the equipment, the entire machine and accompanying accessories should be inspected. If any loss or damage is found due to transportation, the manufacturer should be contacted in a timely manner.

During lifting, the unit should be subjected to force on the chassis and attention should be paid to force balance to avoid damaging the unit.

Warning! It is strictly prohibited to lift the unit on the lifting device of the water pump and diesel engine to avoid damaging the components such as the diesel engine and water pump.

1.3 The equipment should be installed on a stable and sturdy cement foundation without obvious vibration indoors. After the equipment is positioned, it should be leveled and fixed with anchor bolts or expansion bolts at the foot holes of the chassis. Drainage ditches and sewage collection tanks should be set up around the equipment for easy drainage and cleaning of pollutants.

When installing indoors, the hot air discharged from the diesel engine through the radiator should be directed as much as possible towards the outside. When there are difficulties, it is necessary to maintain a suitable exhaust distance from obstacles to facilitate ventilation and heat dissipation of the unit.

1.5 Users should make their own exhaust pipes and elbows. The elbows should not be too long, too many, or have too little curvature to avoid affecting the output power of the unit. When the exhaust pipe is connected to the outside, the pipe mouth should be slightly inclined downwards.

Attention: When installing shock absorbers, please select the correct model and brand of shock absorber.

1.6 The exhaust pipe should be connected to the diesel engine through a flexible joint to avoid assembly stress caused by misalignment and cracking of the connecting parts.

1.7 The fuel tank can be customized by the user or ordered directly from the manufacturer. The fuel tank capacity should usually meet the working requirements of the unit for 4-6 hours. The installation height of the fuel tank should not be lower than the height of the diesel engine oil delivery pump, generally around 1.5 meters. The oil delivery pipe can be connected with a reinforced plastic pipe or other fittings with a diameter of 10 × 1.

1.8 The inlet pipe should be equipped with independent supports and should not rely on the pump body to support weight. Flexible joints should be installed as much as possible on the inlet and outlet pipelines of the pump to facilitate pipeline connection and reduce vibration during operation.

It is best to install the pressure gauge on the outlet pipe at a distance of twice the diameter from the flange, rather than near bends and valves, to avoid interference from unstable flow.

2. Preparation before startup

2.1 Before starting the engine, check if the engine oil is sufficient. The oil level indicator should be above static full and below dynamic full (STOP). When the check is below the lower mark, add the same amount of engine oil.

Attention: Diesel engines generally use 15W/CF40 diesel engine oil.

Warning!! It is strictly prohibited to use different grades or brands of engine oil at different temperatures to avoid damaging your engine.

2.2 Before starting up, check whether the cooling water of the diesel engine is sufficient (until the radiator is filled), and check whether all water valves are closed.

2.3 Before use, check whether the fuel is sufficient (depending on the user's own power generation situation) and whether the air in the fuel system has been exhausted.

Attention: Diesel engines generally use 0 # diesel. When the temperature is below 5 ℃, please use -10 # or lower grade diesel.