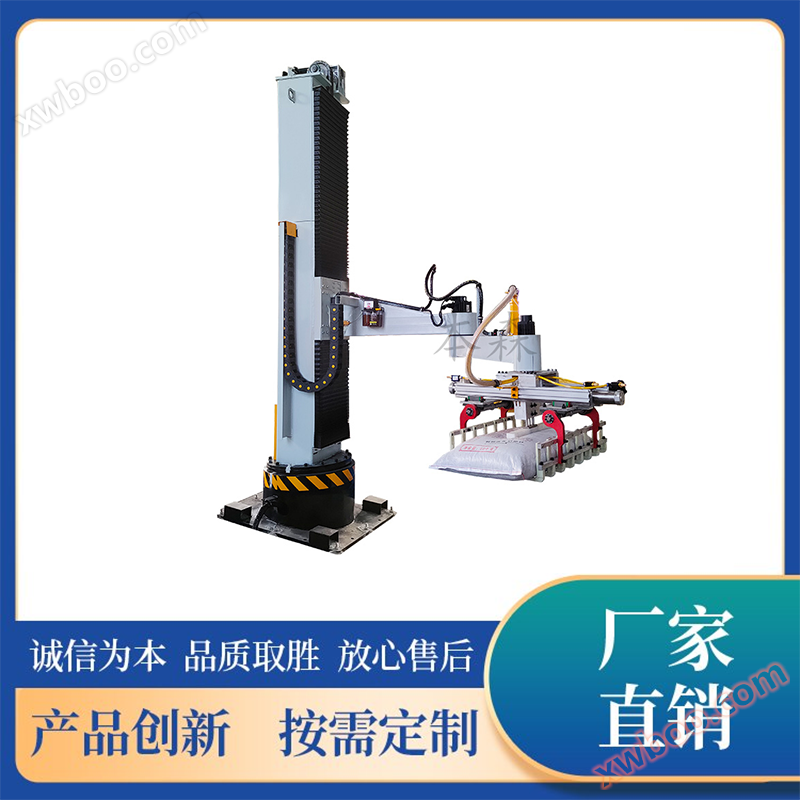

The Shandong Bensen corn flour column palletizing robot is one of the key equipment in modern automated production lines, mainly used to achieve automatic stacking and sorting of corn flour bagged products at the end of the production line. These types of robots usually use advanced robot technology and control systems to efficiently and stably stack the quantitatively packaged corn flour bags continuously produced on the assembly line according to preset stacking requirements through precise grasping, moving, and placing actions.

In the cornmeal production line, palletizing robots can significantly improve production efficiency, reduce labor costs, ensure standardization and safety of the palletizing process, and reduce the risk of product contamination and work-related injuries caused by manual operations. In addition, palletizing robots generally have flexible programming capabilities and can adapt to changes in packaging specifications and stacking requirements, achieving 24-hour uninterrupted operation, greatly improving the automation level and overall production capacity of the entire production line.

Shandong Bensen cornmeal column palletizing robot is one of the key equipment in the

modern automated production line, which is mainly used to realize the automatic stacking

and sorting of cornmeal bagged products at the end of the production line. This kind of robot

usually adopts advanced robot technology and control system, and through precise grabbing,

moving and placing actions, the quantitatively packed corn flour bags continuously produced on

the assembly line are continuously palletized according to the preset palletizing requirements.

In the cornmeal production line, the palletizing robot can significantly improve production efficiency,

reduce labor costs, ensure the standardization and safety of the palletizing process, and reduce the

risk of product contamination and work-related injuries that may be caused by manual operation.

In addition, palletizing robots generally have flexible programming capabilities, which can adapt to

changes in different packaging specifications and palletizing needs, and achieve 24-hour uninterrupted

operation, which greatly improves the automation level and overall production capacity of the entire production line.