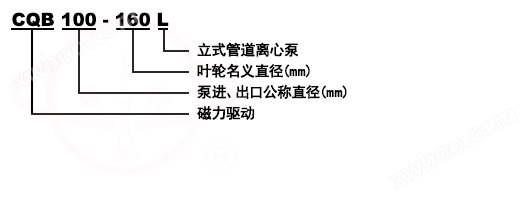

Model significance

Product Introduction

The CQB-L vertical pipeline magnetic centrifugal pump is a new type of pipeline pump developed by our unit based on years of experience in designing and manufacturing horizontal magnetic pumps. It has both the characteristics of ISG pipeline centrifugal pumps and the advantages of magnetic chemical pumps. The installation size is the same as that of ISG pipeline centrifugal pumps, and it is a new generation of leak free pipeline centrifugal pumps.

Product Features

1. Perform leak free operation, capable of transporting flammable, explosive, highly toxic, and corrosive media;

2. The material is excellent, and the pump body, impeller, isolation sleeve and other overcurrent components are all made of high-quality stainless steel;

3. The shaft sleeve is made of high wear-resistant silicon carbide and tungsten carbide, and the sliding bearing is made of carbon stone M106K, with a lubricating oil groove installed to effectively ensure the service life of the pump;

4. Vertical installation, compact structure, small footprint;

5. Low vibration, low noise, and smooth operation;

6. The vast majority of pump components are interchangeable with CQB magnetic drive centrifugal pumps, and the performance of the pump is the same as the CQB magnetic pump series; Q=3.2-100m3/h; H=20-80m; N=0.75-75Kw

Scope of application

CQB-L vertical pipeline magnetic centrifugal pump can be widely used in chemical, pharmaceutical, petroleum, electroplating, food, film photography and printing, scientific research institutions, national defense industry and other units to pump acid, alkali, oil, rare and precious liquids, venom, volatile liquids, as well as supporting circulating water equipment and filter machines. Especially for the pumping of liquids that are prone to leakage, flammable, and explosive, this pump is more ideal.

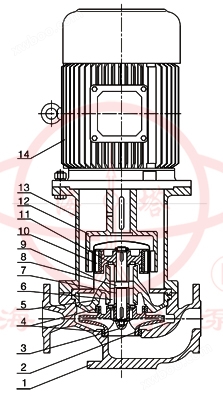

structural diagram

|

serial number |

name |

serial number |

name |

1 |

pump casing |

8 |

pump shaft |

|

2 |

impeller |

9 |

Isolation sleeve bearing seat |

|

3 |

impeller nut |

10 |

Internal magnetic rotor |

|

4 |

sealing ring |

11 |

thrust ring |

|

5 |

bearing housing |

12 |

External magnetic steel assembly |

|

6 |

Sliding bearing seat |

13 |

connection frame |

|

7 |

bushing |

14 |

motor |

performance parameters

model |

Traffic Q (m3/h) |

head (m) |

Speed n (r/min) |

Efficiency η (%) |

Motor power (Kw) |

CQB32-125L |

3.2 |

20 |

2900 |

30 |

1.1 |

CQB32-160L |

3.2 |

32 |

2900 |

28 |

1.5 |

CQB40-105L |

6.3 |

12.5 |

2900 |

39 |

1.1 |

CQB40-125L |

6.3 |

20 |

2900 |

35 |

1.1 |

CQB40-160L |

6.3 |

32 |

2900 |

32 |

2.2 |

CQB40-200L |

6.3 |

50 |

2900 |

25 |

4 |

CQB50-85L |

12.5 |

8 |

2900 |

49 |

0.75 |

CQB50-105L |

12.5 |

12.5 |

2900 |

47 |

1.1 |

CQB50-125L |

12.5 |

20 |

2900 |

39 |

3 |

CQB50-160L |

12.5 |

32 |

2900 |

39 |

4 |

CQB50-200L |

12.5 |

50 |

2900 |

31 |

7.5 |

CQB50-250L |

12.5 |

80 |

2900 |

25 |

15 |

CQB65-125L |

25 |

20 |

2900 |

45 |

5.5 |

CQB65-160L |

25 |

32 |

2900 |

45 |

7.5 |

CQB65-200L |

25 |

50 |

2900 |

35 |

15 |

CQB65-250L |

25 |

80 |

2900 |

37 |

18.5 |

CQB80-125L |

50 |

20 |

2900 |

55 |

7.5 |

CQB80-160L |

50 |

32 |

2900 |

55 |

11 |

CQB80-200L |

50 |

50 |

2900 |

50 |

18.5 |

CQB100-125L |

100 |

20 |

2900 |

56 |

11 |

CQB100-160L |

100 |

32 |

2900 |

55 |

18.5 |

CQB100-200L |

100 |

50 |

2900 |

53 |

30 |

CQB100-250L |

100 |

80 |

2900 |

48 |

45 |

Common causes and solutions of malfunctions

Fault phenomenon |

Root cause analysis |

exclusion method |

The pump is not producing water |

1. Reverse rotation of water pump 2. Air leakage in the inlet pipe 3. Insufficient water storage in the pump chamber 4. Voltage too high, coupling slips during startup 5. The suction distance is too high 6. The valve is not open |

1. Adjust the direction of motor rotation 2. Eliminate air leakage 3. Increase water storage capacity 4. Adjust voltage 5. Lower the installation position of the pump 6. Correct or change the valve |

Insufficient traffic |

1. Suction pipe diameter size or blockage 2. Impeller channel blockage 3. Head too high 4. Insufficient rotational speed |

1. Replace or clean the inlet pipe 2. Clean the impeller 3. Turn up the outlet valve 4. Restore rated speed |

Head too low |

1. Excessive traffic 2. The speed is too low |

1. Turn down the outlet valve 2. Restore rated speed |

The shower noise is too loud |

1. The pump shaft is severely worn 2. Severe wear of bearings 3. External magnetic steel or internal magnetic steel in contact with the isolation sleeve 4. Grinding of sealing ring and impeller 5. Wear of rolling bearings inside the cooling box |

1. Replace the pump shaft 2. Replace bearings 3. Dismantle the pump head and reassemble it 4. Replace the thrust ring and sealing ring 5. Replace rolling bearings |

leakage |

1. O-ring damaged | 1. Replace the O-ring seal |