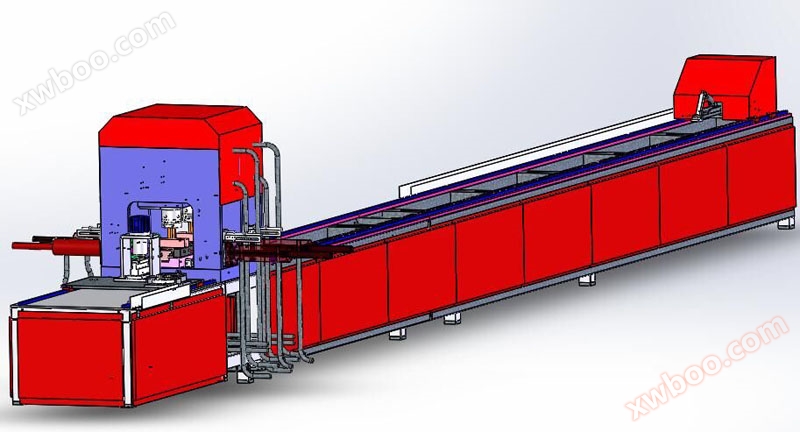

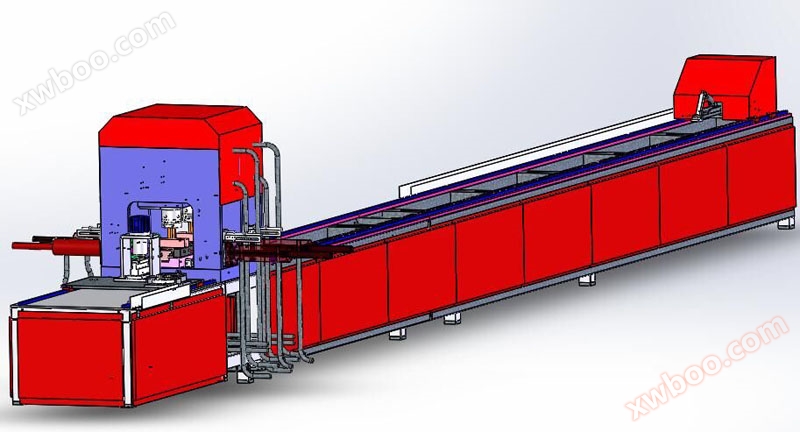

1. Equipment model NLCU-3/4/6

2. Main purpose and characteristics of the equipment

This equipment is mainly used for stamping and processing installation holes on C-shaped steel parts of photovoltaic brackets.

Main features of the equipment:

The equipment can perform CNC feeding on C-section steel with a length of 9500mm according to the established CNC program. CNC hydraulic punching can perform three-axis 6-station stamping or single station continuous stamping, reducing labor intensity, ensuring quality, and high efficiency.

Convenient mold replacement: The unique upper and lower mold installation structure makes it easy and convenient to disassemble the mold without using heavy wrenches.

The manufacturing of upper and lower molds is simple.

Using a CNC system specifically designed for stamping ensures more reliable performance and easier maintenance.

Well configured, with main accessories being branded products.

The front and rear clamps are clamped, and there is no dead zone during operation.

The operation is simple, one person can operate it, and the efficiency is extremely high.

The whole machine is simple, occupies a small area, and has a beautiful appearance.

The C-shaped steel CNC punching machine is a high-speed automated production equipment developed by our company for photovoltaic bracket C-shaped steel,

It has the characteristics of high precision, high efficiency, and labor saving. One clamping can complete the punching processing of three sides of C-shaped steel,

Very suitable for large-scale production.

|