1、 Overview:

The BMZ (BMJ) type gas booster centrifugal blower is a new type of gas exhaust blower developed by Zibo Mingbo Fan Co., Ltd. based on the development trend of two-stage gas stoves and combined with single-stage gas stoves. It fundamentally solves the problem of long-term dependence on imported or Roots blower for high noise and flow rate that cannot be adjusted. Since its launch on the market, the operation has proven that the machine has low noise The performance curve is flat and the flow regulation area is large efficient. Low energy consumption, especially the good sealing performance of the fan, has been highly praised by users.

This machine can rotate clockwise or counterclockwise, with outlet angles of 0 degrees, 90 degrees, and 180 degrees respectively. Users can choose according to their actual pipe distribution needs.

2、 Purpose:

This machine is specifically designed for gas pressurization in factory and mine gas stations Blast furnace Coke oven Converter gas pressurization and ammonia gas Gas with strict airtightness, such as biogas.

3、 Structural features:

This type of fan is a plate welded integral structure, mainly composed of the following components:

1. Impeller. The impeller is the heart of the entire fan, so the blade profile of the fan is optimized and designed according to the new effective fan theory. The material is made of stainless steel or alloy according to different needs, which has good corrosion resistance and sufficient strength. After the impeller is formed, it passes through static Dynamic balance correction, with an accuracy of G4 level (higher than the national standard G6.3 level).

2. Chassis. Made of high-quality carbon steel welded to the machine base as a whole, ensuring the rigidity of the entire machine. The casing is coated with epoxy resin to enhance corrosion resistance; The upper part of the casing is equipped with a G3/4 steam pipe interface, and the lower part is equipped with a G3/2 drain valve; The inlet and outlet flanges of the fan adopt standard flanges to facilitate the connection of user pipelines.

3. Sealing group. This seal mainly uses soft packing and centrifugal sealing, with no vulnerable parts inside the seal. The structure is very simple, the effect is particularly reliable, and it is easy to replace.

4. Motor. The motor matched with this machine adopts Y series or explosion-proof motor, with explosion-proof grade d Ⅱ BT4 and protection grade IP44

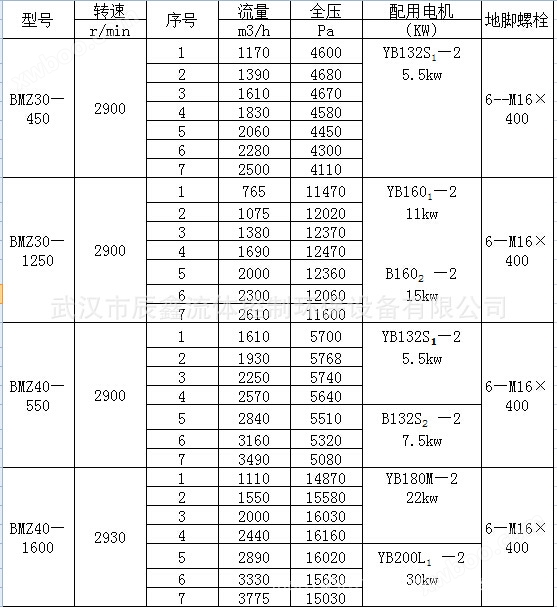

4、 Performance parameters: