Overview of 50p screw chiller

Advantages of 50p screw chiller

🔰 Safety and Environmental Protection 🔋 Efficient and energy-saving 💎 Excellent quality 🎯 High precision

The 50p screw chiller compressor is an energy adjustable oil injection compressor. Its three continuous processes of compression, exhaust, and suction are achieved through the periodic volume changes generated by the rotation of a pair of interlocking male and female rotors inside the engine. Generally, the female rotor is the driven rotor and the male rotor is the active rotor.

The selection of a 50p screw chiller should be considered based on its purpose and cooling load. For refrigeration systems that operate under low load conditions for a long time, screw compressor units and multi head piston compressor units are suitable for energy saving and adjustment.

Adopting international brand compressors, matched with high-quality and high-efficiency copper pipes to make evaporators, condensers, and world brand control components, it has the advantages of long service life, high energy consumption, easy operation, low noise, small size, etc. Its exquisite and beautiful appearance design and high-efficiency energy-saving reliability are stable, with low failure rate and high stability!

Performance characteristics of 50p screw chiller

Performance characteristics of 50p screw chiller

efficiency

Screw chillers have the characteristic of forced gas transmission, which means that the gas transmission volume is almost unaffected by pressure. High efficiency can still be maintained within a wider range of work.

Balance and vibration

Screw compressors do not have reciprocating mass inertia force and have good power balance performance. Screw compressors belong to rotary compressors and do not have centrifugal or reciprocating compression motion. And the pressure vibration of its compressed exhaust is very low, because when the screw rotates, the recovery compression occurs 6 times per cycle, and even if a coin is placed during the compression operation, it will not fall due to vibration.

Gas transmission coefficient

Screw refrigeration compressors have different gas transmission coefficients under different operating conditions, approximately ranging from 0.7 to 0.92. The lower limit is taken when the gas transmission volume is small and the high pressure ratio is low, and the upper limit is taken when the gas transmission volume is large and the low pressure ratio is low. Due to the absence of inlet and outlet valves and clearance volume in screw compressors, the application of new tooth profiles and oil injection greatly improve the sealing and cooling effects. Therefore, its gas transmission coefficient is higher than that of piston and other types of rotary compressors, and the variation is flat.

Gas transmission regulation

The gas transmission volume adjustment slide valve is a structural component used in screw refrigeration compressors to adjust the gas transmission volume. Although there are various methods for adjusting the gas transmission volume of screw refrigeration compressors, the use of slide valve adjustment has been widely applied. By using the method of refluxing some of the working fluid in the elementary volume to the suction chamber, the elementary volume value is reduced (delaying the starting position of the compression process), thereby achieving stepless adjustment of the gas transmission volume.

50p screw chiller function

Adopting a microcomputer control system, it has powerful functions such as safety protection, communication, fault diagnosis, and automatic adaptation.

By adopting intelligent control, the unit can automatically adjust the output of the input compressor according to load changes, so that the unit can maintain optimal cooperation with high efficiency at any time.

The compressor is equipped with an unloading energy control device, which can achieve multi-stage or stepless energy regulation. It adopts an advanced 5:6 gear ratio imported semi closed twin-screw compressor.

The 45p screw chiller unit has a compact structure, small footprint, simple pipeline design, only requires external water pipes, and is easy to install and maintain.

The main refrigeration components are selected from domestic and foreign brand products, with superior performance and reliable operation.

The 50p screw chiller has an open structure, with a beautiful appearance and a simple structure. The operation of the unit can be checked at any time, and installation and maintenance are simple and convenient;

The models of 50p screw chillers adopt single compressor or multi compressor combined refrigeration systems, which are convenient for energy regulation and more energy-efficient at partial loads. The compressor can change the load and automatically alternate operation, balancing the operating hours of each compressor, achieving the effect of saving energy consumption and extending the service life of the chiller unit.

Pressure protection: automatic protection devices for high and low pressure in refrigeration systems;

Power protection: undervoltage protection, phase loss protection, reverse phase protection, overload protection, motor overheating protection;

Anti freezing protection: When the temperature of the chilled water is too low, the unit will automatically shut down;

Safety valve protection: When the refrigerant pressure exceeds a certain value, the safety exhaust valve will automatically open;

Delay protection: Compressor delay start protection to prevent frequent compressor starts;

Oil level protection: activate the protection device when the oil level of the compressor is too low;

Water flow protection: When the water flow stops or decreases, continuing to operate will harm the unit and the unit will automatically shut down;

Principle of 50p screw chiller

Classification of 50p screw chillers

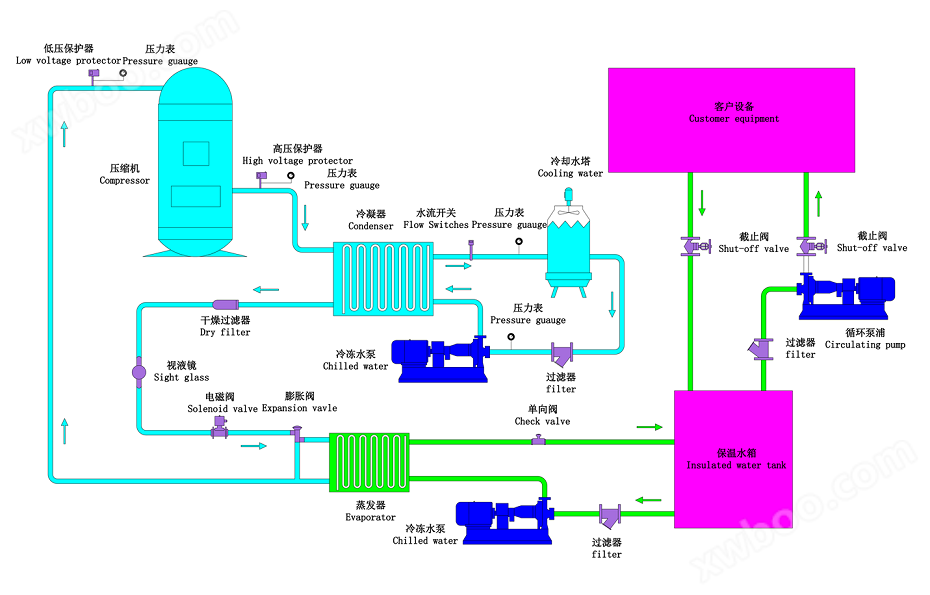

The water-cooled screw chiller is mainly composed of a compressor, evaporator, condenser, refrigeration accessories, electronic control system, etc. When a company purchases a water-cooled screw chiller for installation, it is necessary to purchase additional auxiliary equipment for heat exchange to provide the circulating cooling water required by the water-cooled screw chiller. The supporting auxiliary equipment includes: cooling water tower, circulating water pump, and double-layer stainless steel insulated water tank.

The configuration of air-cooled screw chiller is the same as that of water-cooled screw chiller, but the condenser type is different. It uses a fan to dissipate heat, so a finned condenser is used to continuously exchange heat with the air. Therefore, air-cooled screw chillers do not require a cooling tower, but require a circulating water pump and a double-layer stainless steel insulated water tank.

Screw chillers are divided into industrial screw chillers, medium temperature screw chillers, and low-temperature screw chillers according to the range of water supply temperature.

1. Industrial screw chiller unit

We can provide 5-15 ℃ chilled water or use ethylene glycol solution as a refrigerant. We can provide -5~+5 ℃ process chilled water solution, which can be used as a process cold source for ice storage, low-temperature air supply, central air conditioning, and other production processes. At the same time, I can design the unit according to user requirements and provide large temperature difference chillers (with an inlet and outlet water temperature difference of 8-15 ℃). Or higher than the water temperature unit (outlet temperature 15 ℃~25 ℃). The cooling capacity is 94KW-3360KW.

2. Medium temperature screw chiller unit

The outlet temperature ranges from -5 ℃ to -45 ℃, and an imported semi enclosed screw compressor unit (with an economizer) is used; We can provide low-temperature ethylene glycol solution or saline solution ranging from -5 ℃ to -45 ℃. Can be used as a cold source for processes such as chemical, pharmaceutical, cold storage, and ice rinks. The cooling capacity is 55KW-2000KW.

3. Low temperature screw chiller unit

The outlet temperature ranges from -45 ℃ to -110 ℃, and it can provide frozen water of alcohol or calcium chloride solution at -45 ℃ to -110 ℃; Adopting binary or ternary cascade screw refrigeration systems. Features such as high energy efficiency and stable operation.

At the same time, special industrial screw chillers can be designed according to usage requirements, including ultra-low temperature, anti-corrosion, and explosion-proof types, which can meet the requirements of various industries for process cooling sources.

Application of 50p screw chiller in the industry

| ✅ | Plastic and rubber industry | Control the mold temperature of various plastic processing methods, shorten the molding cycle, and ensure stable product quality |

| ✅ | Petroleum and Chemical Industry | Aggregation, condensation, distillation, melting, dehydration, forced insulation |

| ✅ | oil industry | Temperature control and cooling of reaction vessels for fatty acid distillation, oil decomposition, concentration, esterification, vacuum deodorization, etc |

| ✅ | synthetic fiber industry | Aggregation, melting, spinning, stretching, drying |

| ✅ | Textile printing and dyeing work | Heat setting roller, drying room heating, heat capacity dyeing |

| ✅ | Nonwoven industry | non-woven fabric |

| ✅ | Pharmaceutical Industry | Used for temperature control of fermented drugs, pharmaceuticals, and biological products; Low temperature and low humidity environment is required during production and storage |

| ✅ | Paper industry | Dry and corrugated paper processing |

| ✅ | chemical fiber industry | Freeze dry air to ensure product quality |

| ✅ | Construction work | Supply chilled water for concrete to make the molecular structure of concrete suitable for building use requirements, effectively enhancing the hardness and toughness of concrete |

| ✅ | Machinery industry | Control the pressure and oil temperature of the hydraulic system, stabilize the oil temperature and pressure, prolong the use time of oil quality, improve the efficiency of mechanical lubrication, and reduce wear and tear |

| ✅ | food industry | Used for high-speed cooling after food processing to meet packaging requirements |

| ✅ | Air conditioning industry | Cooling for industrial plants and civil buildings |

| ✅ | Control machine tools, coordinate boring machines, grinding machines, precision machine tools | Spindle lubrication and cooling of hydraulic system transmission medium |

| ✅ | Light industry, raw material processing, electronic products | Production lines for ink, laundry detergent, lithium batteries, LED lights, etc |

| ✅ | electroplating industry | Control the electroplating temperature, increase the density and smoothness of the plated parts, shorten the electroplating cycle, improve production efficiency, and enhance product quality |

| ✅ | vacuum coating | Control the temperature of the vacuum coating machine to ensure high quality of the coated parts |

| ✅ | Other industries that require constant temperature and cooling |

Service process of 50p screw chiller

💯 Xingde Machinery provides you with efficient and thoughtful service experience, solving your temperature control problems! 💯

◆ Professional and technical personnel conduct research to comprehensively understand the actual needs of customers ◆ Free consulting services and feasible technical selection plans ◆ Coordinated on-site inspections to confirm models ◆ Nationwide door-to-door delivery, strong freight logistics support ◆ Logistics tracking to ensure timely delivery ◆ Irregular customer follow-up, tracking after-sales service ◆ One year warranty for the entire machine, lifelong maintenance and upkeep!