Product Features

◆DC5V; 7-30V; 24V Power supply optional;

◆Relay output contact isolation;

◆The communication interface supports RS485 or RS232 (two different versions, the communication serial port can only support one);

◆Communication baud rate: 2400480096001920038400 (can be modified through software, default 9600)

◆Communication protocol: Supports standard Modbus RTU protocol;

◆You can set 0-255 device addresses, and the 5-digit address dip switch can set 1-31 address codes. For addresses greater than 31, they can be set through software;

◆Equipped with flashing and breaking functions, it can include parameters in the command and operate the relay to automatically turn off after a period of time;

◆It has a strobe function and can control the periodic switching of relays.

PRODUCT FUNCTION

◆twoRelay control, two-way DI input, two-way AI input;

◆Supports 5-digit addressing addresses;

◆Support manual control through computer software;

Product Selection

Main parameters:

Interface Description:

wire connectionway

Relay wiring method

Schematic diagram of passive input wiring

Analog wiring diagram

Second line system:

Three wire system:

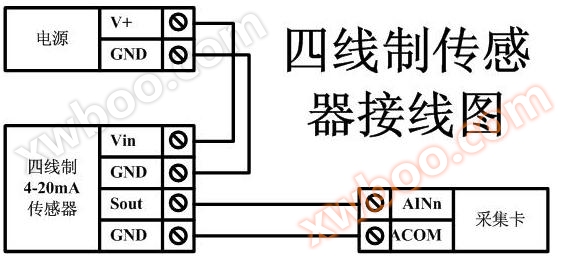

Four wire system:

232 wiring instructions

RS485 wiring diagram

Test software description

http://www.juyingele.com.cn/software/software/DAM Debugging software. rar (software video tutorial link)

Software functions:

Relay status inquiry

Relay independent control

Analog reading

Switch status query

Debugging information query

Change of working mode

Setting of offset address

Relay overall control

Working mode functions and settings

Connected Device

http://www.juyingele.com.cn/software/software/DAM Debugging software. rar (software video tutorial link)

Open the "Juying Soaring DAM Series Configuration Software"; Serial port settings bar: Select the corresponding COM port of your computer for the serial port, choose the default baud rate of the device (9600) for the baud rate (before setting the baud rate yourself), fill in the device address as "254" (254 is the broadcast address of the device), select the corresponding device model, set the four parameters of the above device, and clickOpen serial portClick the relay button“JD1”If the relay responds, the connection is successful.

Method for changing device address

Introduction to device address

The device address can be changed through a dip switch, please refer to the dip switch address table below for details.

Introduction to the Address of the Device Dialing Switch

1. When all five dialing codes are dialed to the "ON" position, it is the address "32";

2. When all five dialing codes are dialed to the "OFF" position, it is the address "1";

3. The leftmost 1 is the binary lowest bit.

4. Address Table:

Reading and Setting of Baud Rate

Click on "Read" and "Set" in the baud rate settings bar below to read and set the baud rate and address respectively. After the operation, you need to restart the device and modify the computer serial port settings.

Flashing function and settings

Introduction to the Flashing and Breaking Function

Manual mode: For each operation of the relay, the relay will flip once (open when closed, close when open);

Flashing mode: For each operation of the relay, the relay will close for 1.5 seconds and then automatically disconnect;

Flashing mode: For each operation of the relay, the relay will disconnect for 1.5 seconds and then self close;

Flashing and disconnecting settings

Open the "Juying Soaring DAM Series Configuration Software" and click the dropdown arrow after the relay mode to select the mode.

Example of Communication Instructions

This product supports standard Modbus instructions. For detailed instruction generation and parsing methods, please refer to the register table in this article and consult the "MODBUS Protocol Chinese Version".

Modbus protocol Chinese version reference:

http://www.juyingele.com.cn/software/software/Modbus%20POLL Software and User Tutorial. rar

Modbus Register Description

This control card is mainly a coil register, which mainly supports the following instruction codes: 1, 5, 15

Coil register address table:

remarks:

① Modbus device commands support the following Modbus addresses:

00001 to 09999 are discrete outputs (coils)

10001 to 19999 are discrete inputs (contacts)

30001 to 39999 are input registers (usually analog inputs) 40001 to 49999 are holding registers (usually storing device configuration information)

Using a 5-digit code format, the first character determines the register type, and the remaining 4 characters represent the address. Address 1 starts from 0, such as 00001 corresponding to 0000.

② Table of baud rate values correspondence

③ Relay status can be queried through address 30002 or address 00001--00002, but control can only use address 00001--00002.

The data length of 30002 address is 16 bits. It can represent up to 16 relays.

The corresponding results are as follows:

The bit 8 of the data in register 30009 is the same as the data in register 00001.

Similarly, the same goes for optocoupler input. The bit8 and bit9 of register 30003 and registers 10001 and 10002 correspond to the specified hardware.

The register address follows the PLC naming convention, where the real address is obtained by removing the highest bit and then subtracting one.

Instruction generation instructions

Application example and explanation: In addition to the dip switch address, the default broadcast address for this device is 254. When there is only one device on the bus, there is no need to worry about the dip switch address. Simply use the 254 address. When there are multiple devices on the bus, select different addresses through the dip switch and send control instructions based on address differentiation.

Note: The RS485 bus can mount multiple devices.

The instructions can be obtained through the debugging information of the "Juying Soaring DAM Series Configuration Software".

Instruction generation instructions: For instructions not listed in the table below, users can generate them themselves according to the Modbus protocol. For reading and writing relay coils, it is actually reading and writing coil registers in the Modbus register. The address of the relay register has been explained in the previous text, and users only need to generate read and write instructions for register operations. For example, reading or writing the status of relay 1 is actually a read/write operation on the coil register 0001 corresponding to relay 1.

Detailed explanation:

Control 1 relay (taking the first circuit as an example, refer to this example for other channels)

Send code: FE 05 00 00 FF 00 98 35

Relay card return information:

Return code: FE 05 00 00 FF 00 98 35

1: Relay inquiry

Query 2 relays

FE 01 00 00 00 02 A9 C4

Relay card return information:

FE 01 01 00 61 9C

2Query optocoupler (4-channel optocoupler)

Send command code: FE 02 00 00 02 ED C4

Optocoupler return information:

Return code: FE 02 01 00 91 9C

3. Query analog data (2-channel 4-20mA)

Send command code: FE 04 00 00 00 02 65 C4

Return information:

Return code: FE 04 04 00 00 00 00 F4 8B

4. Flash development code: FE 10 00 03 00 02 04 00 04 00 0A 00 D8

Flashing sending code: FE 10 00 03 00 02 04 00 02 00 14 21 62

Return code: FE 10 00 03 00 02 A5 C7

4. Analysis of fully open and fully closed commands

Full development code: FE 0F 00 00 02 01 FF D1 D3

Total disconnection sending code: FE 0F 00 00 02 01 00 91 93

Complete disconnection and full open return code: FE 0F 00 00 02 C0 05

Common problems and solutions

1. After the relay board is powered on, communication cannot be established using the 232 interface and cannot be controlled

Firstly, test whether different baud rates can be controlled. Pay attention to the A+, B-line, and shielded line of the 485 interface. Shielded line is not necessary, but it must be connected in cases of high communication error rate, even if the distance is very close.

On the 2.485 bus, with more than one device mounted, I sent the relay 1 draw sum with broadcast address 255, but not all modules have relay 1 draw sums.

When there is only one device on the bus, the broadcast address can be used. If there are more than one device, please use a dip switch to distinguish the address for control. Otherwise, the module may not execute instructions correctly due to asynchronous judgment of communication data.

3. Siemens PLC and equipment cannot communicate normally

The definition of Siemens 485 bus AB is opposite to that of equipment